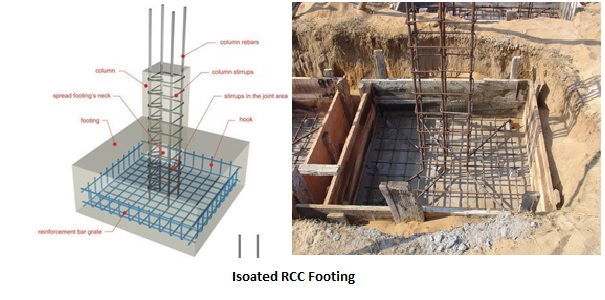

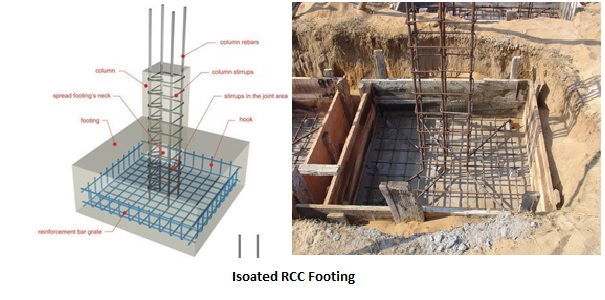

Foundation of any structure is like roots of a tree which holds total weight and give stability to the structure.Before designing foundation structural engineers asses depth of strata the type of fit for resting the foundation considering its bearing capacity.

Foundation is part of structure which lies below the plinth and transfers load from superstructure to footing finally terminating too

Footing is the structure which is in contact with ground and distributing load over a larger area,rcc footings are done in load bearing structures. Footing plays very critical role in overall structure stability of a building, before initiating RCC Footing there are various things we need to keep in mind so that it achieve its purpose over buildings lifespan.

Checks and tips for RCC footing

- Check top surface of pcc is in level using Spirit level or tube Level for uniform and balanced distribution of load over footings. PCC makes steel cage not coiming in direct contact with soil strata, its right level ensure that the structural grade concrete is consumed as per design and better cover to bottom reinforcement are maintained.

- Check inside dimensions of shuttering (Length,Breadth,Depth) is as per size, shape and dimension proposed by architectural and structural engineer. Ensuring the footing structural requirement.

- Ensure that joints between shuttering and formwork are water tight such that there will be no slurry losses leading to honeycombing or unpleasant finish. Visible Gaps between shuttering panels to be closed using shuttering tape etc.

- Check alignment and position of footing is as per centerline proposed by architect using measurement tape and strings preferably using level. Measure center to center distance between footings.

- Ensure that shuttering provided to rcc footings are strong / sturdy enough to take a load of concrete.

- Check formwork used for reinforcement is clean and defect free. For plane, smooth RCC footing.

- Check Diameter, number of bars, spacing between bars and position of bars is as per structural drawings.

- Ensure effective depth of rcc footing is as per structural. Effective Depth= Total size of RCC footing – Cover.

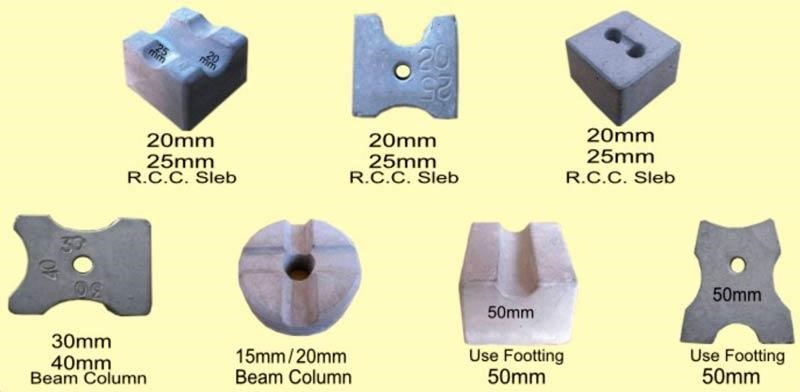

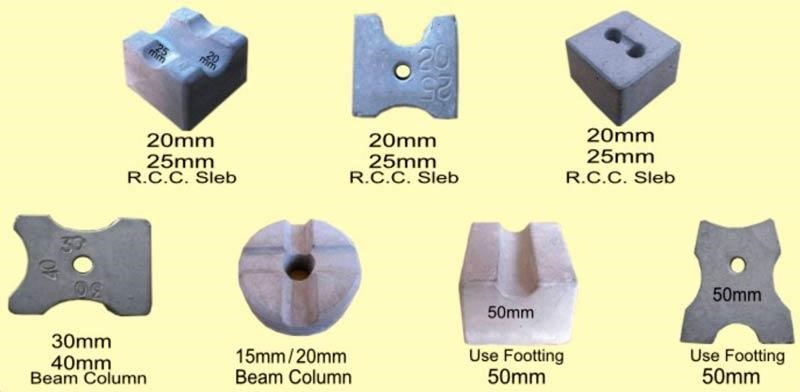

- Cover to RCC footing to be maintained as recommended by structural designer. Cover is a distance between reinforcement and shuttering which protects deterioration of steel embedded in RCC ,due to exposure conditions.

Generally there are two types of cover available in market according to concrete grade.

- Ensure support is provided to column reinforcement is stable so that column should not tilt.

- Concrete pour height should be less than 1.5mts, to avoid segregation of concrete mix. Necessary arrangements like chute, pump etc. can be made to restrict concrete fall below 1.5m.

- Proper concrete compaction to be ensures using needle vibrators for better in-situ results.

Points to remember while Casting Foundation

before Pouring Concrete

- Ensure that there are proper safety provisions on construction site like helmet, safety shoes, gloves etc.

- Place proper lighting provisions on site for smooth working in night.

post Shuttering Removal

- Curing for RCC Footing should be done at least for 10 days from the date of concreting.

- If any honeycombing, bulging, crack found on RCC footing then rectify it by using proper method statement as recommended by structural engineer.

- Remove all nails, binding wires, concrete flakes from finished footing.

Important Note: Backfilling can be done only after 03 days curing period of all footings are over,if schedule permits delay as much as possible.