Brickwork is masonry produced by using mortar and bricks. Brickwork provides a natural pleasing aesthetic to structure. Brick masonry provides high durability as during construction, one layer is laid upon another and avoiding a continued line of joints for two or more layer or course, moreover, an appropriate bond is formed adhering bricks together by filling joints with mortar. Standard brick size for modular brick is 200mm x 100mm x 100mm, including 10mm mortar thickness.

Workmanship simply means the grade of skills used to deliver the required tasks. Poor workmanship can result into lower quality work, higher cost for maintenance and even failure of structure. It can take as long as a year for defects or faults to surface after the completion of structure.

Defects in Brickwork Due to Poor Workmanship

1. Failure to Fill Bed Joints

A higher work pace or weak supervision and during furrowing practice, the bed joint filling might be improper. During practice of furrowing, a long and narrow trench is made in mortar bed with the tip of his trowel, i.e. a gap is created in middle of mortar bed parallel to face of wall.

A reduction in strength as much as 33% can be noted due to incomplete filled bed joints. However, a significant impact in noted on flexural resistance rather than on compressive strength and moreover, filling of vertical joints is quite difficult than horizontal joints.

Further inevitable problems with respect to sound insulation and weather exclusion are caused as result of unfilled perpendicular joints. Furrowing practice must be avoided and a considerable work pace must be attained.

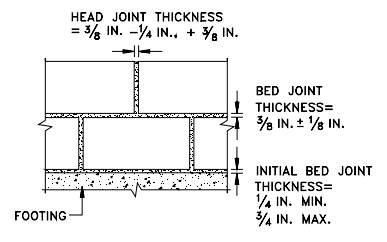

2. Excessive thickness of Bed Joints

An effective reduction in compressive strength of masonry is noted with increase in thickness of bed joints as the larger thickness of bed joints results in larger lateral tensile stresses in comparison to thin bed joints.

Thus, a too thick joint increases chances for collapse of member or structure under working loads. For example, a bed joint that is 16 mm to 19 mm thick possesses up to 30% less compressive strength than the bed joint that is only 10 mm.

3. Deviation from alignment or Verticality

One of the main issues with the brick walls is their vertical alignment, that’s why a plump is always used to check for verticality at certain work points. If masonry brickwork is constructed without use of plumb, there might be unnecessary deviations from required vertical alignment.

This resulting deviations will result into extra amount of eccentric loads and moreover, an effective reduction in strength. For example, a brick wall that possesses deviation of 12 mm to 20 mm from required alignment might possesses up to 15% less strength than the walls with no such defect.

4. Exposure to Adverse Weather

Exposure to hot weather may cause a substantial moisture loss, due to which cement hydration might remain incomplete and desired strength is not attained by mortar. Newly constructed brickwork must be prevented from exposure to high heat or very low temperature conditions.

Due to low temperature or freezing might cause reduction in strength due to abnormality vertical alignment. To reduce impacts of these adverse conditions, polythene sheets could be used to cover brickwork in hot conditions and in freezing weather, strategy of heating construction materials might be adopted.

- Masonry construction practices must be done under favourable temperature conditions : 4 deg C to 37.8 deg C

- In case temperature is greater than 32.2 deg C along with wind velocity greater than 12.9 Km per hour implicates hot weather requirement. In such case, protect materials from direct sunlight and use cool mixing water and maintain mortar consistency. Fog spray newly constructed masonry unit for a minimum of 3 times a day for not less than 3 days after completion.

- For freezing conditions, do not lay masonry units at temperature below -6.7 deg C . Heat the surface without causing any damage. Heat mixing water to produce mortar at recommended temperature, but do not heat water or aggregates above 60*C. Protect newly constructed masonry by covering with a resistive membrane for at least 24 hours after completion

5. Failure to Adjust suction in Bricks

During construction of slender walls with using absorptive bricks, a significant amount of water is absorbed by the bricks. Due to this loss of water from mortar, its shape changes from flat to pillow shape and the mortar might not be able to return to its original shape as along with loss of water from mortar there is substantial movement of bricks.

These conditions might result into unstable brickwork due to curving and swelling out shape of mortar and corresponding loss of strength. To avoid this condition, pre-wetting of bricks and addition of lime to mortar mixture to resist water suction is recommended.

6. defects due to incorrect Mixing and Proportioning of Motar

Use of unnecessary amount of plasticizer or use of high water to cement ratio can result into a weak or lean mortar i.e. reduced strength of mortar. Proper considerations must be kept while deciding for bricks of required crushing strength and corresponding mortar strength and proportioning. A slight change in any of the strengths (brick or mortar), majorly affects the masonry.

– Tushar Meena