Kota stones are fine-grained naturally available limestone. Quarried at Kota district of Rajasthan, India, it is one of the most preferred building stone for exteriors, driveways, pathways, corridors, balconies, etc. It also finds its application in flooring of chemical industries for its inertness towards a large number of chemicals.

These stones are available in different finishes (Smooth and rough) and in wide variety of earthy colours with brown being the most popular. It’s also available in Black, Beige, Grey and Pink. It outstands other stones in similar applications for its homogeneity, hardness and non-porous properties.

Different colours of Kota Stone

Specifications for Laying Kota Stone Flooring

1. Stone Slabs

The slab should be of desired quality, hard, dense, homogeneous and free from any cracks, decay, weathering, etc. It could be either hand or machine cut for the required thickness. The exposed face of slab should be polished before being placed at site and also the contractor shall get the slab sample approved by the concerned Engineer.

Kota Stone Slabs

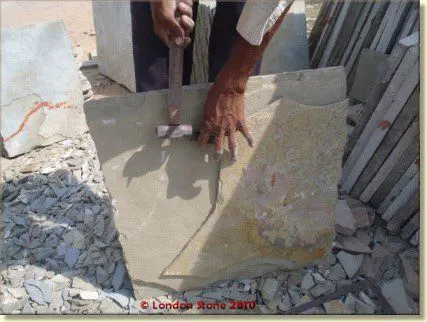

2. Dressing of Slab

Each slab shall be tailored to the required size and shape and chisel dressed along the sides to obtain a straight edge. The edges shall be either table rubbed or machine rubbed with coarse sand before paving.

Utmost care should be taken to ensure all angles and edges are true, square and free from chippings. Tolerance of ±2mm is acceptable for thickness. With respect to length and breadth of the slab, a tolerance of ±5mm and ±2mm for hand cut and machine cut respectively is acceptable.

Fine Chisel Dressing of Kota Stone

3. Preparation of Surface

The surface (usually concrete) upon which the slabs are to be laid should be cleaned, wetted and mopped. The bedding mortar of slab shall be of specified thickness.

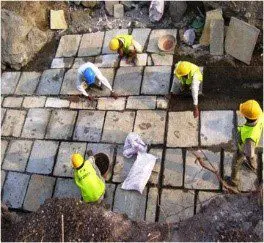

4. Laying of Kota Stone

Mortar of specified mix (usually 1:4 Cement : Coarse Sand) is prepared and spread under the area of each slab for the indicated thickness (usually 20mm).

The cleaned slab is laid on top, pressed and tapped with a wooden mallet in order to bring in same level of the adjoining slab. The slab is then lifted and placed aside. The top surface of the mortar is made uniform by filling up the hollows with fresh mortar and is allowed to harden.

The mortar is then topped with cement slurry of honey like consistency at the rate of 4.4 kg of cement per square meter. The slab to be laid is lowered gently back in its position. Subsequent slabs are laid in similar manner and the excess grout coming out of the joints of the slab is cleaned off.

Laying of Kota Stone Slabs

5. Curing, Polishing & Finishing

The curing of slab by wetting the surface shall be continued for a minimum period of seven days. Thereafter the surface shall be ground evenly with a machine fitted with fine grade grit block (No. 120). After grinding the surface should be prepared by thoroughly washing and cleaning for final grinding. Final grinding is done the day after the first grinding with machine fitted with the finest grade grit blocks (No.320).

Hand polishing may be allowed instead of machine polishing for small areas after laying. In case of hand polishing carborundum stones of medium grade (No. 80) and fine grade (No. 120) shall be used for first and final polishing respectively.

The polished surface is then rubbed hard with oxalic acid sprinkled with water and spread at the rate of 33 gm per square metre using pad of woollen rags, also known as namdah block.

6. Acceptance Criteria

The finished surface shall be intact and free from loose stones. A wooden mallet tap on the surface shall not produce hollow sound. The joints shall run parallel to the adjoining walls and shall not be too wide or too narrow.

Advantages and Disadvantages of Kota Stone Flooring

Advantages of Kota Stone Flooring

- Kota Stones have wide application in exterior works for its non-porous, non-absorbent, tough and homogenous properties and is an excellent building stones for both humid and freezing regions.

- Availability of the stones in slab and tile form makes it convenient to achieve different pattern of flooring.

- It gives rich aesthetics to both interior and exterior flooring and is cheaper than other stones used in similar application.

- High customization can be achieved because of its availability in sizes of 30×30, 40×40, 30×60, 40×60, 60×60, 50 x50, 55×55, and 60×90 centimetres.

Disadvantages of Kota Stone Flooring

- Unlike granite or marble Kota stone slabs are not available in bigger sizes. This is because of its fragile nature.

- On a longer run Kota stones flakes out. However if well maintained and polished regularly the flaking of stones can be intercepted to a greater extent.

- The finished surface is not as glossy or luminous as that of marble and granite.