Formwork by name means “The Mold” which means it is the casing into which the casting material, usually concrete, is poured to obtain the desired structural shape.

In construction industry formwork is similar to a mold to cast concrete member in different shape and sizes using different types of materials such as timber, steel, aluminum, plastic, etc. Shuttering is a synonym term used for form-work. Form work should have sufficient strength to carry dead load and live load coming on it during casting operation and after that till concrete gets hard and gain some percentage of design strength.

Requirements of good Formwork

- It must be capable to withstand all types of dead and live

- It is practically good to have water proof character, so that it won’t absorb water from concrete.

- Entire formwork should be rigidly constructed and propped, so that there should be no deformation in the shape and retain its original shape.

- Deflection and shrinkage should be minimum.

- The joins should be tight enough to minimize the leakage of cement grout.

- The formwork should be constructed with different segments. So that while removing the formwork it should not damage the concrete

- The material of the formwork should be cheap, easily available and should be suitable for reuse.

- The formwork should be set accurately to the desired line and levels should have plane surface.

- It should be as light as possible. So that it is easy to transfer and erect.

- The material of the formwork should not warp or get distorted when exposed to the elements.

Different Types of formwork – Based on Material

1. Timber formwork

The Timber formwork is one of the mostly used type in construction industry, fabricated on site using timber. It is easy to produce but time-consuming for larger structures. We can’t produce curved shapes economically. Timber shuttering should satisfy the following requirement:

- Lightweight

- Well-Seasoned

- Free from termite attacks

- Easily Workable

2. Plywood Formwork (In Combination with Timber)

Plywood is an artificially manufactured wooden material available in different thickness and size used in formwork for concrete member. It is strong enough, durable and light weight. The main advantage of this forms from timber forms is we get smooth cement surface with this form.

3. Steel Formwork

Steel formwork is now becoming popular due to its long-life time and multiple time reuses. Steel formwork is costly but can be used for large number of projects. Steel shuttering give very smooth finishes to concrete surface. It is suitable for circular or curved structures such as tanks, columns, chimneys, tunnel and retaining wall.

4. Aluminium Formwork

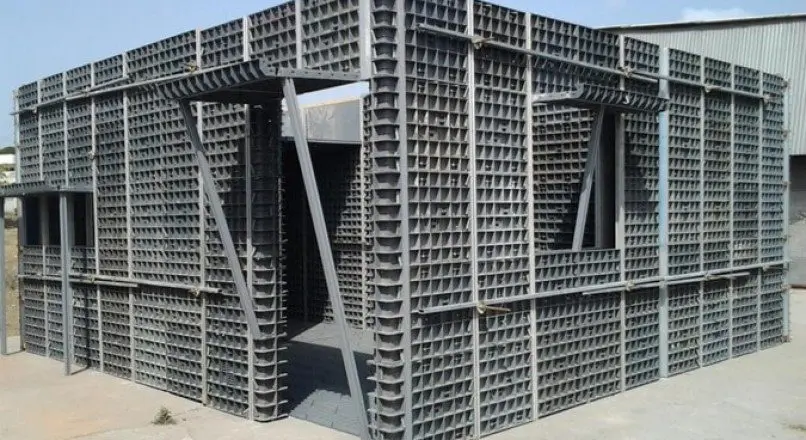

Aluminum formwork is almost similar to those made of steel. Aluminum forms are lighter than steel forms due to low density and this is their primary advantage when compared to steel. The shuttering is economical if large numbers of repeating usage are made in construction. The disadvantage is that no alteration is possible once the formwork is constructed.

5. Plastic Formwork

Plastic formwork is lightweight, posses interlocking mechanism and could be used for multiple times. Plastic shuttering is mostly useful where similar construction shape structures are required.

6. Coffor Formwork

Coffor is a structural stay-in-place shuttering used in concrete construction. Coffor is made of two filtering grids, in which vertical stiffeners are reinforced. After the placement of coffor formwork, concrete is poured between the grids and excess water is drained through grids due to gravity.

7. Fabric Formwork

Fabric formwork is used for construction of complex and irregular shaped member. Usage of fabric formwork provides an opportunity for construction of efficient and architecturally marvellous structural members of any shape and sizes.

Different Types of Formwork – Based on Structural member they are used for

1. beam formwork

Beam formwork consists of pre-assembled form sheeting parts. A method for cover straps is used for nailing of sheeting boards together for providing sheeting base and side panels. The extent of work is dependent upon width and thickness of sheeting base and cover straps and the width of thrust board. A whaler is mounted at the upper edge of side sheeting to hold together the forms by wire ties. The whaler and segments are propped by diagonal sheets.

2. Coloumn Formwork

The sheeting of column formwork is prefabricated, depending upon required column dimensions. Steel bolts are used to anchor the sheeting panels in foot rim. Vertical arch timbers are placed to take the forces from cover straps of formwork sheeting. The diagonal board braces are used to tie the column in formwork laterally

3. Wall Formwork

Wall shuttering consists of vertically arranged upright formwork bearers and sheeting boards are nailed to it, at concrete side. Moreover, upright timbers are braced diagonally by using boards at both sides. The opposite whalers must be tied at specific distances and cleaning holes are to be allocated at the foot of formwork.

4. Foundation Formwork

Foundation formwork are designed differently for different foundation types and sizes. Formwork specifications will be different for isolated and strip foundation. The design of formwork is mainly dependent on size and depth of foundation. Metal screws and tie wires are used as formwork ties and generally sheeting panels are used along with formwork bearers for foundation formwork.

5. Slab Formwork

System of ceiling shuttering provides ease in transport, assembling and stocking. Ceiling formwork has optimum stability and time is saved while assembling and disassembling. The basic elements of ceiling shuttering are wooden beam beams and steel supports and it doesn’t require much expertise.

Technical requirements of Good Formwork

- Formwork should be exactly designed of the required shape and size so that it fits at the designed position.

- According to the desired concrete surface the material of the formwork will be selected.

- Formwork should be strong enough to withstand the pressure of fresh concrete and working loads and should not distort or deflect from their position during the concrete placing operation.

- Formwork should support the designed horizontal and vertical loads. It should also support the other unusual loads also during the construction period.

- The formwork should not disturb the structure or concrete surface during the removal time.

- The segments of the formwork should be tightly fitted to minimize the gaps between them which prevents the leakage of cement material.

Functional Requirements of Formwork

- Form segments should be of suitable size so that they can be transported and stored easily and reused at another place.

- Formwork should be easy to dismantle and fit so that construction of building process advances.

- Formwork segments should have symmetry so that they can be interchangeable and can be used at different places.

- Forms should be simple to build.

- Formwork should be as lightweight but with enough strength required to withstand the loads and pressure.

- Forms should be made such that workers can handle them without any safety issue, respecting the Health, Safety, and Hygiene Regulation in effect.