The concrete is a mixture of cement, sand, aggregates and water which, when placed in the skeleton of forms followed by curing becomes hard like a stone. The standard method of evaluating the quality of concrete in buildings or structure is to test specimens for compressive, flexural and tensile strength.

Several destructive and non destructive tests are performed on concrete to determine its strength and various informations relating to strength of concrete.

Destructive Tests on Concrete

As the name suggest, after destructive test the concrete specimen gets destroyed and is not available for further use. In destructive testing, tests are performed till the failure of specimen to understand the behavior of material under different loading conditions. These tests are much easier and yields more information as compared to non destructive tests.

Non Destructive tests on Concrete

Non destructive testing is an in-situ method of evaluating the concrete structure for its strength and durability. This test apart from indicating the strength, also indicates the other characteristics of concrete in relation to presence of voids, cracks depth, micro cracks and deterioration of concrete. Moreover, after the performance of this test, specimen can further be used as testing is done without loading the specimen till failure.

The range of properties that can be assessed using non-destructive tests and partially destructive tests is quite large and includes such fundamental parameters as density, elastic modulus and strength as well as surface hardness and surface absorption, and reinforcement location, size and distance from the surface. In some cases it is also possible to check the quality of workmanship and structural integrity by the ability to detect voids, cracking and delaminating.

Advantages of Non-Destructive Tests

- No damage to the main structure.

- NDT methods are valuable in detecting flaws and defects in concrete as well as determining the depth and thickness of concrete.

- NDT can also be applied to old structures.

- NDT can prevent accidents.

- Monitoring long term changes in concrete properties.

- Determines the position, quantity or condition of reinforcement.

Disadvantages of Non-Destructive tests

NDT is simple but it requires skilled and experienced persons having some knowledge to analyze the test.

Non-Destructive Testing Methods

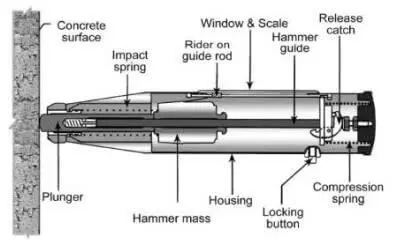

1. Schmidt rebound hammer test

Rebound hammer consists of a spring control mass that slides over the plunger in tubular casing. When the hammer is pressed against concrete surface to be tested, it retracks against the force of the spring carrying along the rider with it. Movement of which is noted over the scale and is referred as rebound number which is further used to indicate the strength of concrete.

The result of this test depends on several factors as:

- Smoothness of the surface under the test

- Internal and external moisture conditions

- Age of the specimen

- Size, shape and rigidity of the specimen

- Types of coarse aggregates and mould used

- Type of cement used

- It also depends on the angle on which rebound hammer is placed

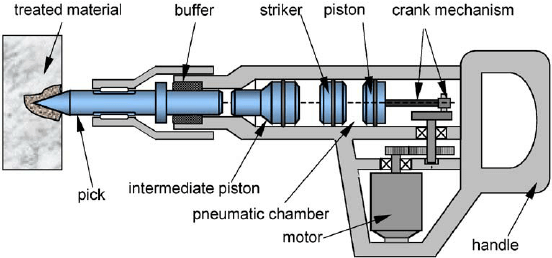

2. ultrasonic Pulse Velocity Test

The principal of this test is based upon the fact that velocity of the sound in solids depends upon the modulus of elasticity and density of the solid.

The apparatus of this test consists of a transmitter and receiver. Transmitter is used to generate the pulse of ultrasonic frequency i.e. detected by the receiver placed on the other face of the specimen.

The time required by the pulse to travel through the known distance in the specimen is noted which is further used to calculate the velocity of the pulse, which is related with the quality of the concrete under the test.

Results of this test also depends upon several factors:

- Smoothness of the surface under the test.

- Temperature of the specimen.

- Reinforcement used in the specimen.

- Internal and external moisture conditions.

3. Penetration Resistant Tests

Penetration resistance test offers a means to determine relative strength of concrete in same or different structures. Some mainly used penetration devices are as follows,

1. Windsor probe

In this device, a gun powder actuated driver is used to fire a hardened alloy probe into the concrete. During testing, it is the exposed length of probe which is measured by calibration depth gauge.

2. Pin penetration test

Pin penetration is used for concrete having low strength i.e. less than 28 N/mm2 . A device is used to drive a steel pin into the concrete. The penetration of pin creates a small hole on the surface of concrete. The hole depth is measured with a depth gauge after removing the pin. The strength of mortar and aggregates influences the penetration depth of pin in concrete.

4. Radio Active Methods

Radioactive methods of testing concrete can be used to detect the location of reinforcement, measure density and perhaps establish whether honeycombing has occurred in structural concrete units. The equipment is quite simple and running costs are small, although the initial price can be high. Concrete up to 45 cm thick can be examined without difficulty.

– Anand Singh