Reinforcement is an important building material which withstands loads from all component parts of structure. It also resists seismic loads experienced by sub structure. Due to aging, reinforcement steel get damaged due to various factors and excessive loading.

Hence, it is necessary to repair/maintain them. Reinforcement is provided in sub surface component parts like foundation and super structure component parts such as beam, column, slab, lintel, chajja, staircase, etc.

Common Defects in Structural Elements in Old Buildings

- Buckling in column (vertical steel bars )

- Bending in beam (horizontal steel bars)

- Corrosion in steel bars

- Excessive yielding

- Elongation of steel bars

Causes of Defects in Reinforcement steel in Structural Elements

- Improper installation of steel bars

- Poor workmanship and improper execution

- Faulty material

- Faulty design of RCC

- Excessive loads from structure (sub and super surface)

- Seismic waves

- Natural Disasters

- Water logging and seepage

- Soil / mortar erosion

- Fixtures and fittings of pipes

- Movement of structures

- Temperature / humidity / moisture content

- Improper maintenance

- Termite attack / Fungal decay / chemical attack

- Aging of structure

Procedure for Repair of Reinforcement in Old Buildings

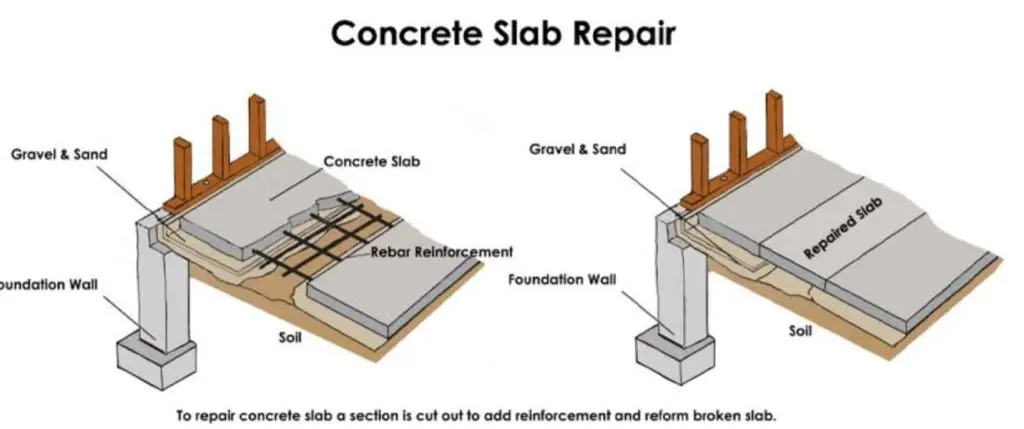

1. Procedure for Repair of Reinforcement Steel In Slab

- Removal of concrete cover

- Cleaning of steel bars with wire brush

- Application of epoxy layer on steel bars

- In case of high corrosion , steel mesh should be added

- Fastening of steel mesh

- Application of new concrete before drying of epoxy material

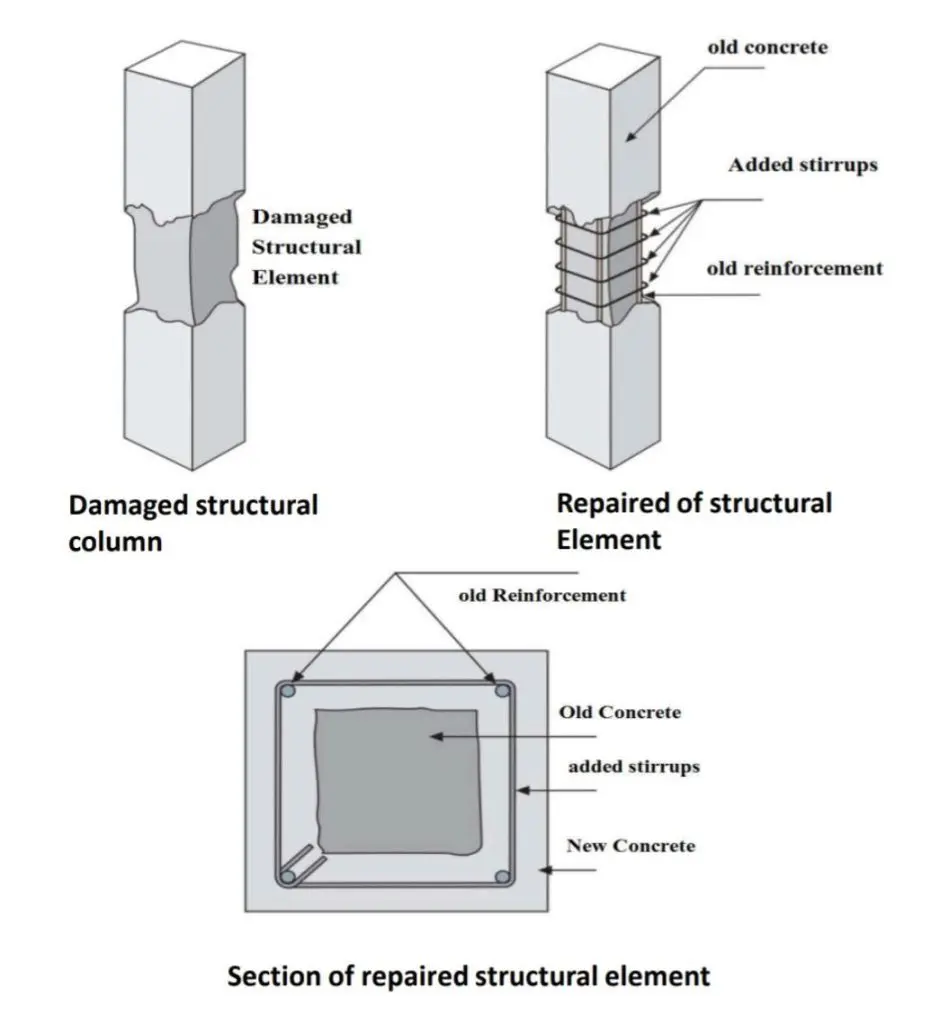

2. Procedure for Repair of Reinforcement Steel in Coloumn

a. reinforcement concrete jacket

- Adding steel connectors to faster new stirrups in both direction. This can be done by drilling holes of suitable diameter and depth

- Inserting epoxy material in holes and further installing the connectors

- Installation of new steel bars and stirrups of jacket as per design

- Coating existing column with epoxy material

- Application of new concrete layer as per required thickness before drying of epoxy

B. Steel Jacket

- Removal of concrete cover

- Cleaning of steel bars with wire brush

- Application of epoxy layer

- Installation of steel jacket of required size , shape , thickness as per design

- Pour epoxy in openings and space between column and jacket

3. Procedure for Repair of Reinforcement Steel in Beams

- Increasing steel bars and cross section area of concrete if beam fails to take required loads

- Increasing steel bars without disturbing cross section area if bars fail to resist stresses

- Adding steel plates to beam if beam fails to resist structural properties like shear stress, moment distribution, etc. Steel plates are designed and added with suitable thickness

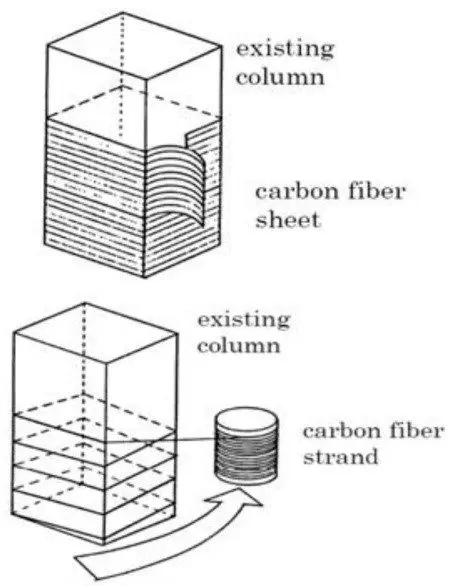

4. Carbon Fiber Wrapping

- Concrete surface is cleaned with wire brush and all dust / loose particles are removed

- Epoxy material is applied on this cleaned surface

- CFRP (Carbon Fibre Reinforcement Polymer) is cut into required dimensions and is placed on the epoxy material

- An overlap of 50mm to 100mm should be maintained while placing 2 adjacent pieces of CFRP on any structural element

- All air voids should be removed by hand pressure while pasting the CFRP on epoxy

- After this, 2nd coat of sealer is applied as final surface

- Let it dry for 24 hours. Apply 3rd coat if necessary

- This technique can be applied on any type of shape of structural element for strengthening purpose

Summary

- Reinforcement in old structures can be repaired

- It is advisory to change the whole part newly instead of temporary repair / adjustments

- Epoxy material can be used to form good bonding between new and old materials after repair

- Repair of reinforcement can be economical over new construction

- Time saver as compared to new construction

- Faulty design , poor material , bad workmanship is wiped out during repair process

- Structural properties of building components are checked and strengthened

– Vrushali Pathak