Aggregate is a granular material, such as sand, gravel, crushed stone used with a cement to produce either concrete or mortar.

Aggregate is relatively inexpensive and does not enter into complex chemical reactions with water; it has been customary, therefore, to treat it as inert filler in concrete and mortar.

However, due to increasing awareness of the role played by aggregates in determining many important properties of concrete and mortar, the traditional view of the aggregate as inert filler is being seriously questioned.

It is true that aggregate strength is usually not a factor in normal concrete strength because, with the exception of lightweight aggregates, the aggregate particle is several times stronger than the matrix and the interfacial transition zone in concrete(from where the concrete starts failing). In other words, with most natural aggregates the strength of the aggregate is hardly utilized because the failure is determined by the other two phases.

There are, however, aggregate characteristics other than strength, such as the size, shape, surface texture, grading (particle size distribution), and mineralogy which are known to affect concrete strength in varying degrees.

Basic Functions of Aggregate

- Cheap fillers

- Hard material

- Provide volume stability

- Reduce volume changes

- Provide abrasion resistance

Nomenclature & Classification of Aggregates

Aggregates are generally classified according to particle size, bulk density, or source sieve

Coarse aggregate is used to describe particles larger than 4.75 mm, and the term fine aggregate is used for particles smaller than 4.75mm.

Fine aggregates contain particles in the size range 75 µm to 4.75 mm, and coarse aggregates from 4.75 to about 40 mm, except for mass concrete which may contain particles up to 150 mm.

Most natural mineral aggregates, such as sand and gravel, have a bulk density of 1520 to 1680 kg/cum and produce normal-weight concrete with approximately 2400 kg/m3 unit weight.

For the most part, concrete aggregates are comprised of sand, gravel, and crushed rock derived from natural sources and, therefore, are referred to as natural mineral aggregates ( are further classified as granite, limestone, basalt etc. depending upon their parent rock source).

Aggregate’s Characteristics and their Significance

Generally, aggregate properties affect not only the concrete mixture proportions but also the behavior of fresh and hardened concrete. Due to considerable overlap between the two, it is more appropriate to divide the study of aggregate properties into three categories that are based on microstructural and processing factors.

Characteristics dependent on porosity: density, moisture absorption, strength, hardness, elastic modulus, and soundness

Characteristics dependent on prior exposure and processing factors: particle size, shape and texture

Characteristics dependent on chemical and mineralogical composition: strength, hardness, elastic modulus, and deleterious substances present.

A knowledge of certain aggregate characteristics (i.e., density, grading, and moisture state) is required for proportioning concrete mixtures. Porosity or density, grading, shape, and surface texture determine the properties of plastic concrete mixtures.

The mineralogical composition of aggregate affects its crushing strength, hardness, elastic modulus, and soundness which, in turn, influence various properties of hardened concrete containing the aggregate.

Properties of Aggregates

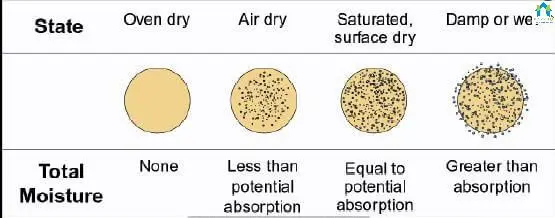

Absorption capacity is defined as the total amount of moisture required to bring an aggregate from the oven-dry to the SSD condition.

SSD Condition : When all the permeable pores are full and there is no water film on the surface, the aggregate is said to be in the saturated-surface dry condition (SSD).

Surface Moisture:

The amount of water in excess of the water required for the SSD condition is referred to as the surface moisture.

Specific Gravity :

Ddefined as the density of the material including the internal pores.

Bulk Density :

defined as the mass of the aggregate fragments that would fill a unit volume.

Soundness :

An aggregate is considered unsound when the volume changes in aggregate induced by weather (e.g., alternate cycles of wetting and drying, or freezing and thawing) ,result in the deterioration of concrete.

IS limit:

Fine Aggregate = 10% (weight loss of five cycles with Na2SO4)

Fine Aggregate = 15% (weight loss of five cycles with MgSO4)

Coarse Aggregate = 12% (weight loss of five cycles with Na2SO4)

Coarse Aggregate = 18% (weight loss of five cycles with MgSO4)

Shape:

Flakiness Index : Thickness being 0.6 times their mean dimension, contributes more surface area for a unit volume occupied.

Elongation Index: Greatest dimension being 1.8 times their mean dimension, contributes more surface area for a unit volume occupied

Mechanical Properties of Aggregates

Crushing strength, impact value abrasion resistance, and elastic modulus of aggregate are interrelated properties that are greatly influenced by porosity. Aggregates from natural sources that are commonly used for making normal-weight concrete, are generally dense and strong; therefore they are seldom a limiting factor to strength and elastic properties of concrete.

BIS limit:

Crushing and Impact Value:

Wearing surface = 30% & Non-wearing surface = 45%.

Abrasion Resistance:

Wearing surface = 30% & Non-wearing surface = 50%.

Sizing and grading of Aggregate

Grading is the distribution of particles of a granular material among various size ranges, usually expressed in terms of cumulative percentage larger or smaller than each of a series of sizes of sieve openings, or the percentage between certain ranges of sieve openings.

Size of aggregate

The maximum size of aggregate is conventionally designated by the sieve size on which 15 percent or more particles are retained. In general, the larger the maximum aggregate size, the smaller will be the surface area per unit volume which has to be covered by the cement paste of a given water-cement ratio.

Since the price of cement may be 10 to 15 times as much as the price of aggregate, any action that saves cement without reducing the strength and workability of concrete can result insignificant economic benefit.

There are several reasons for specifying grading limits and maximum aggregate size, the most important being their influence on workability and cost.

For example, very coarse sands produce harsh and unworkable concrete mixtures, and very fine sands increase the water requirement (therefore, the cement requirement for a given water-cement ratio) and are uneconomical.

Aggregates that do not have a large deficiency or excess of any particular size produce the most workable and economical concrete mixtures.

Fineness Modulus

Empirical factor called the fineness modulus is, often used as an index of the fineness of aggregate, a very important factor when making selection for a source/type of fine aggregates.

The fineness modulus is computed from screen analysis data by adding the cumulative percentages of aggregate retained on each of a specified series of sieves, and dividing the sum by 100. The sieves used for determining the fineness modulus are: No. 100 (150 µm), No. 50 (300 µm), No. 30 (600 µm), No. 16 (1.18 mm), No. 8 (2.36 mm), No. 4 (4.75 mm), 10 mm, 20mm, 40mm etc.

As per our experience Fine Aggregate with F.M of 2.6 to 3.0 are best suited concrete application and Fine Aggregate with F.M of 2.4 to 2.6 are best suited plaster applications

Silt Content

Material finer than 75-µm (No. 200) sieve are generally called silt. They affect the workability as water demand increases; strength is also influenced (lowered) along with bonding. BIS limit is 3% by weight.

By Volume silt to be <12% after 10min.

As river sand are prone to be silty and its dredging from river bed affects environment manufactured sand are slowly replacing them at metropolitan cities.

Concluding Remarks

Aggregate primarily acts as inert filler, but has secondary influences on various concrete and mortar properties. Awareness about the role played by aggregate in concrete and mortar can be instrumental in exploiting the use of the same in achieving concrete & mortar properties as per intended requirements, which would be of high performance and economical.

It is inappropriate to treat the aggregates with any less respect than cement.

You can Buy Quality Verified Aggregate (12mm, 20mm and 40mm) on Our Online Store.