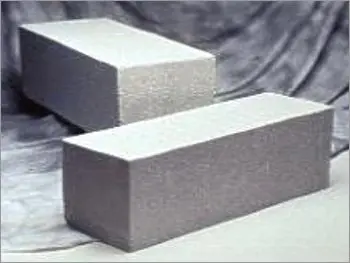

CLC Blocks (Cellular Light Weight Concrete Blocks) are made of Cellular Light weight concrete (CLC) or Foam Concrete. Cellular Light Weight Concrete (CLC) is a light weight concrete that is produced by mixing cement and flyash slurry with pre-formed foam.

These CLC blocks are competitive with red clay bricks in pricing and offer significant savings for finished structures.

Advantages of CLC blocks in Construction

- Light in Weight: The density of CLC blocks vary from 600 to 800 Kg/cum. This is almost three times less than the traditional clay bricks or flyash brciks.

- Reduced Construction Cost: The overall dead load of structure is decreased when CLC blocks are used in construction. By optimizing the design accordingly house owners can save money on major construction materials like cement and steel.

- Eco friendly: CLC blocks are made of material such as fly ash and other industrial wastes. The production process of CLC blocks don’t release any harmful effluents that affects ground, water or air.

- Sound and Thermal Insulation: CLC Blocks are excellent for both Sound insulation and Heat Insulation. This decreases the energy spent on heating and cooling the houses thereby decreasing the electricity costs for the house owners.

- Lower Water Absorption: Due to the presence of air pockets which are not interconnected, the water absorption of CLC blocks are relatively lower than any other materials. This compares much better than concrete 50% and ordinary brick, which has water absorption of around 50% to 80%. The low water absorption property of these blocks will help to reduce the cracks in the walls.

- Fire Protection: Foam concrete blocks offers grate fire protection. With a just 100mm thickness of wall with density of 1000 kg/m3, offers fire endurance for heat transmission for 4 hours without releasing any toxic fumes during the fire. Fire rating of cellular concrete is far superior to that of brickwork or dense concrete.

- Ease to Handling: Due to its less weight CLC blocks are easy to handle and install, thus minimizing the construction costs. They also require lesser materials like cement and sand during construction for bonding.

Where are CLC blocks Used (Applications)?

- Acoustic construction

- Precast exterior walls

- Roof insulation and waterproofing

- Green construction

- Additional floors to existing structure

- Building material for highrises

- Air-conditioned buildings

- Low cost housing

- Subways

Raw materials used in Manufacturing CLC blocks

- Portland Cement

- Flyash

- Water

- Foaming agent

manufacturing Process of CLC blocks

- For manufacturing 1 Cum of CLC bricks approximately 5 Bags of OPC 53 Grade Cement and 500 Kgs of Fly ash is added into a mixer.

- Around 1.2 Kgs of Foaming agent diluted with 30 Ltrs of water is added and mixed thoroughly

- Foaming agent allows airs to entrain the mixture making the slurry light weighted

- One litre of slurry is collected from the mixer and weighed for density. If the required density is achieved, then the slurry is drained into trollies.

- The slurry is then poured into assembled moulds of bricks of required dimension and is allowed to set for 18 to 24 hours.

- Finished CLC bricks are taken to the curing area and are allowed to cure for 28 days. Good curing gives strength and dimensional stability to bricks

- Steam curing is also used in some cases to reduce the curing period. This is suitable for higher production rates. Steam curing requires less labor, less production cost and better finish.

Watch the video on CLC Block Manufacturing Process:

https://www.youtube.com/watch?v=qinP25SuNK0

Standard Sizes of CLC blocks available in Market

CLC Blocks are usually available in the following 4 dimensions:

- 600mm x 200mm x 100mm

- 600mm x 200mm x 150mm

- 600mm x 200mm x 200mm

- 600mm x 200mm x 250mm

How many CLC blocks are there in 1 Cubic meter (Cum)

| CLC Blocks Size | Blocks per Cum |

| 600mm x 200mm x 100mm | 83 Blocks |

| 600mm x 200mm x 150mm | 55 Blocks |

| 600mm x 200mm x 200mm | 41 Blocks |

| 600mm x 200mm x 250mm | 33 Blocks |

Rates of CLC block per Piece

| CLC Blocks | Rate per Piece |

| 600mm x 200mm x 100mm | Rs. 50 |

| 600mm x 200mm x 150mm | Rs. 70 |

| 600mm x 200mm x 200mm | Rs. 90 |

| 600mm x 200mm x 250mm | Rs. 110 |

Note: This is just an approximate cost as of December’2018. The price depends on availability and location and might vary. To get the exact pricing of CLC blocks in your location, you can request for a quote here.