Air entrained concrete is one of the most important development in concrete technology. It was first used in early 1930 especially in USA. The air entrained concrete is manufactured by introduction of any air entraining agents or using air entrained cement which is in turn manufactured by inter grinding air entraining agents to clinkers formed.

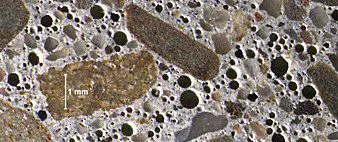

The air entraining agents added reduces the surface tension of the water film on cement particles generating foam, thus forming microscopic voids which are uniformly distributed in the concrete. The air voids are of the size ranging from 5 to 80 microns and mostly in spherical shape.

Entrained air is often confused with entrapped air, the difference is entrained air are microscopic voids, intentionally introduced to improve the properties of the concrete but entrapped air are voids of bigger sizes as a result of improper compaction. Entrapped air will result in degradation of concrete over time.

Effects of Air Entrainment in fresh Concrete and Hardened Concrete

Air entrainment has various effects on both fresh and hardened concrete they are,

Effects of Air Entrainment in Fresh Concrete

- Increases workability: To increase the workability it is necessary that the aggregates and mortar are spaced properly so that they can move freely, in conventional concrete for this purpose the amount cement paste added is to be increased. But by entraining air which can behave has fines it allow the movement of aggregates by lubricating the concrete paste thus increasing workability.

- Reduces segregation and bleeding: We know that segregation is the process of separation of aggregates from mortar and bleeding is the process of emergence of water on the surface of fresh concrete due to sedimentation of heavier material. Entraining air will improve the mutual adhesion between cement and aggregate thus reducing segregation, further the air voids does not allow the heavier particles to settle down thus reducing bleeding considerably.

2. Effects of Air entrainment on Hardened Concrete

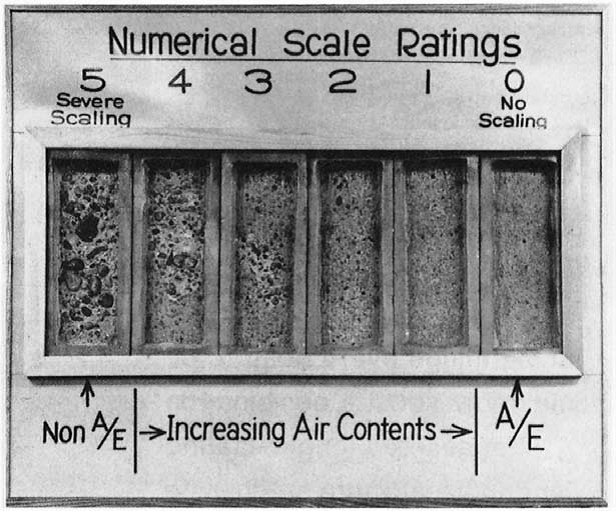

- Reduces scaling: The scaling in concrete occurs due to freezing and thawing cycles, in conventional concrete when temperature falls below freezing point, the water in concrete freezes in the entrapped air voids, since ice has an increased volume it causes plastic shrinkage cracks and scaling on the surface of concrete. But in air entrained concrete since the air voids are microscopic in size the increase in volume of the water freezed will not cause any cracks or scaling.

- Effect on strength: It is often believed that entraining air will reduce the strength of concrete, but if this system is properly implemented we can achieve a very less or no loss in strength.It is true that air entrainment reduces the strength of concrete to certain extent but the entrained air can be used to reduce the water content for a given workability thus it can regain the lost strength.

- It also reduces permeability of concrete, thus in turn increasing the resistance to chemical attack.

The air entrained concrete is designed by taking the air entraining agent as the fifth element in concrete (after cement, fine & coarse aggregate and water). Thus amount of air entraining agent is calculated separately unlike the other admixtures. There are many air entraining agents available, some are listed below:

- Vinsol resin

- Darex

- Sulphated and sulphonated organic compounds

- Animal and vegetable resins and fatty acids

- Natural wood resins

Factors Affecting Air Entrainment

The amount of air entrained in the concrete is affected by variety of factors some are explained below

- Experiments show that increased compaction will reduce the amount of air entrained, because when concrete is compacted the air bubbles escapes through the surface or it is destructed. It is estimated that 50% of air entrainment in lost after compaction for 2½ minutes.

- If the water cement ratio is very low then the air entraining agents cannot form the foam to produce air bubbles, but when the water cement ratio is too high initially more air bubbles are formed but they are lost with time. So moderate water content is preferred (0.4 to 0.6).

- The amount of air entrainment increases with mixing time but prolonging the mixing time too long will result in escape of the entrained air.

- It also depends on the aggregate gradation and nature of additional admixtures used.

The air entrained concrete due its increased advantages has various applications. It is best suited in places of very low temperature since it is good at resisting freezing and thawing effects. For this reason it was widely used in United States and Canada. In India it is not popular because our climatic conditions never demanded resistance to freezing and thawing. The air entrained concrete has been found best suited for multipurpose dam constructions. Some structures built using air entrained concrete are

- Hirakud dam.

- Koyna dam.

- Rihand dam etc.,