With the increasing blend of biology with architecture and engineering, there have been many new innovative materials that have come up, experimented with and invented in recent years. One of the biggest challenges to building with concrete is the material’s tendency to crack both while it’s drying and in the coming years when it is under active usage.

This can happen due to forces and loads, both internal and external. In such situations and encounters, biocement plays a very important role in making a building sustainable as well as self-healing.

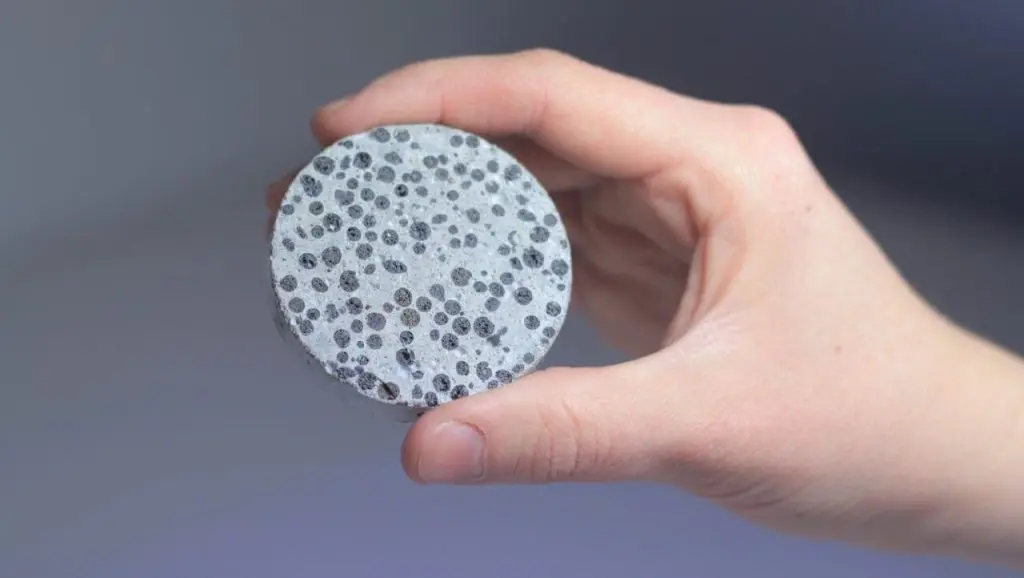

Biocement has been continuously experimented and now invented and practised with; today it plays a critical part in architecture and the results obtained are extremely promising. Biocement, like ordinary concrete is made from Portland cement, water, coarse and fine aggregates and other admixtures; what stands out here is the addition of a mixture of bacteria and capsules of calcium lactate.

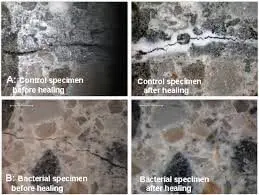

When cracks start to form, while drying or post drying, calcium lactate in presence of water reacts and forms calcite that fills in the gaps created by the cracks.

How Bio cement works

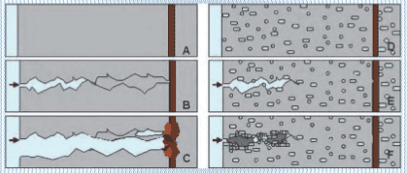

(Schematic representation of how biocement is different and more efficient than ordinary cement.

Diagrams A, B, C represent how ordinary concrete reacts to cracks and how there is no self-healing and repair taking place. Whereas diagrams D, E, F represents how biocement reacts to a crack caused.)

Biocement also uses microorganisms in soil to produce a strong and renewable material with minimal impact on environment. It is a living building material that is capable of reacting to stress independently of human intervention.

Biocement Bricks

When we think of applications of biocement in detached individual houses, biocement bricks are the most preferred media. These can be grown. Instead of requiring significant amount of heat in the production process, these bricks are created using a bacterial by-product to fuse sand particles together and form a durable building material.

These bricks consist of biomass, aggregates, renewable nutrients and minerals that are placed into moulds and then treated with a type of bacteria that is fed with calcium ions and water. This process results into formation of calcite shells which are used as biocement bricks or blocks. The process takes about two or three days.

Advantages of Biocement

- Biocement takes shorter time to be processed and prepared when compared to ordinary cement. This makes it more suitable for in-situ process.

- Raw material of Biocement van be produced and manufactured at low temperatures, which is more efficient compared to an ordinary cement which uses temperatures up to 1500 degree Celsius in production process

- Biocement can be used as eco-construction material since it consumes less energy and releases less carbon emissions in the production process unlike ordinary cement.

- It increases compressive strength of mortar by up to 40% making it more resistant towards stresses and forces.

- It can remediate cracks and regain strength within 28 days through its self-healing properties.

- In case of ground movement (Earthquakes) or violent impacts, biocement has the ability to repair itself without any external support or maintenance.

Disadvantages of Biocement

- The method of producing biocement is more complex than the ordinary chemical cement as the microbial activity is completely dependent on environmental factors like temperatures, humidity, concentration and diffusion rates of nutrients and metabolites.

- Successful commercialisation of the technique requires economical alternatives of the medium ingredients that cost as high as 60% of the total operating costs.

– Janvi Mangukiya