When concrete ingredients (Cement, sand, aggregate and water) are mixed together, the water causes the hardening of concrete through a process called hydration with cement. Hydration is a chemical process where cement reacts with water and form hydrates.

More the quantity of cement hydrates, the more will be its concrete compressive strength. This chemical reaction is exothermic, which means it releases heat during reaction.

This heat and external environment can make the available water in the concrete to escape and there would be less cement getting hydrated as amount of water available for hydration will reduce, majority of designed cement will remain unreacted.

To avoid this freshly casted concrete is kept in sufficiently wet or humid conditions till the required strength is achieved (usually up to 7 – 14 days),curing at early ages is very important ,once a concrete is deprived of curing it is a dead concrete, can’t be revived.

Curing is a process of controlling the rate and extent of moisture loss from concrete to ensure an uninterrupted hydration of cement once the concrete is placed and finished in the position.

Why is Curing Important?

Curing helps in the following ways:

- Reduces the loss of water required for cement hydration process, thus will help in gaining the required strength for concrete

- Improves durability of concrete by reducing permeability and porosity

- Improves microstructure of concrete.

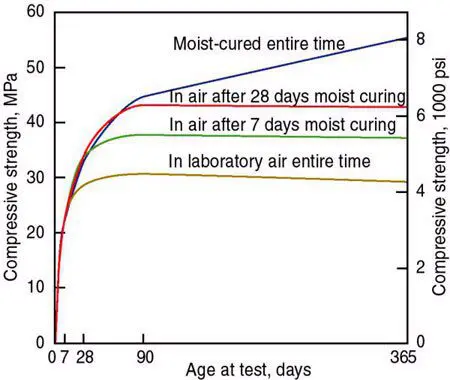

From the above graph it is evident that curing increases the compressive strength of concrete.

Right time to Cure Concrete:

1. Immediately after placement of concrete, water bleeds to the top of the surface as plastic settlement occurs. During this stage, if the rate of evaporation of bleed water is greater than the rising water, plastic shrinkage of the concrete occurs. Concrete Mix design can be done to counter the external environment or concrete placement may be done early morning/evening. Mist curing may be arranged if concrete placement cannot be rescheduled.

2. Wet hessian cloth can be place on finished concrete surface, as soon as the surface is hard enough to walk upon.

3. Once the concrete finally is set, curing should be done meticulously as per any of the procedure mentioned in the article.

Duration of Curing:

Concrete should not be allowed to dry fast in any situation. This condition should be maintained for 24 hours. Best way is to keep the concrete under wet hessian/gunny bags for 24 hours and then commence water by way of water ponding or spraying.

The curing period varies for different structures, situations, different atmospheric conditions, type of cement and grade used and mix proportion.

In general, concrete must be cured at least for 7 days if Ordinary Portland Cement is used. If rapid hardening cement is used, the period can be reduced slightly. If low heat cement is used curing can be extended to 14 days. In cold weather regions, curing should be continued for a long time.

Methods of Curing:

Curing can be broadly divided into three different ways:

1. Water Curing

2. Membrane Curing

3. Steam Curing

4. Miscellaneous methods for curing

1. water curing

Water curing prevents moisture form drying up of surface thereby allowing the hydration process to take place

A. Sprinkling or Spray Curing

One of the simplest and basic forms of curing cconcrete. In this method, Water is sprayed onto concrete using a hose or a bucket at frequent intervals through out the day. This method is suitable for small works like bungalow construction or construction of any small concrete structures. Water has to be sprayed every time the concrete surface dries up. So this method requires great care and supervison.

b. Ponding Method

Ponding is the most common and inexpensive method of curing a flat surface like slab or road pavements. Small shallow ponds are prepared on the top of the surface using clayey soil or cement mortar. Water is filled and stored up to a depth of 50mm for required period (usually 28 days). Care should be taken so that the water in the pond doesn’t dry up. Water used in ponding should be of good quality and should not contain any harmful chemicals or salts that will damage the concrete.

c. Wet covering with Hessain or Gunny Bags

This method is very useful for vertical surfaces of concrete like sides of column and maintaining the moisture during the initial setting phase of concrete. Gunny bags, cotton mats, rugs etc., which are water absorbent can be used to maintain the water on concrete surface by completely covering the concrete surface once it has set. These materials absorb water and retain moisture for long time. These materials have to be kept moist continuously to prevent the fabric from absorbing the water from concrete surface by capillary action.

2. Impermeable Membrane Curing

Membrane curing is used in areas of acute water scarcity. Water mixed while preparing fresh concrete is generally sufficient for the entire hydration reaction. In this method a sealing membrane is applied over concrete which will trap the water inside and avoid its escape through evaporation. Membrane may be actually a sheet of polythene or formed by application of chemicals.

Different sealing compounds used in membrane curing are:

- Rubber latex emulsions.

- Bituminous and asphalt emulsions.

- Emulsions of paraffin or boiled linseed oil.

3. Steam Curing

Steam curing is a process of accelerating the hardening of concrete by quickening the hydration process. This type of curing is mostly used for precast structures and products. Due to steam, the components are heated uniformly and the strength is gained evenly at a very fast rate.

There are two ways of steam curing.

Low Pressure Steam Curing: In this method the steam curing is done at atmospheric pressure and about 70% of the 28-days strength can be achieved in 16-24 hours.

High Pressure Steam Curing: In this method steam curing is done at a pressure of 8 atmospheres that is 800KN/m2. Main disadvantage in fast curing is that rapid rise of temperature cause loss of strength. This difficulty is minimised with application of high pressure. High pressure steam curing gives high durability to concrete.

In developed nations, other forms of thermal curing are also employed to concrete to accelerate the gain of early concrete strength

4. Miscellaneous Techniques

A. Curing by Infrared Radiation

IR radiation is also used for curing concrete in some developed countries with cold climates. In this method, the frameworks are heated electrically

B. Electrical curing Method

Large electrical blankets are used to heat the slab surface which will give early strength to the concrete. Alternatively electrical current (AC only) is made to pass through the freshly laid concrete between two externally fixed electrodes.