Concrete mix proportions are designed to achieve it desired properties it’s placing, compaction and curing are also critical to realize potential of a concrete as an end product.

Mixing, transporting, and handling of concrete should be cautiously synchronized with placing and finishing operations. Concrete should not be deposited more rapidly than it can be spread evenly, struck off, consolidated and finished to its final position.

Planning concrete pour plays important role to achieve above along with its placing, compaction and finally finishing.

Step by Step Procedure for Concrete pouring and finishing

Step-1: Planning Concrete Pour:

- Approach to reach the placing area should be free from any traffic obstruction, ensuring concrete placement with least lag.

- Periphery/Spaces to receive concrete are clear free from debris and free from water.

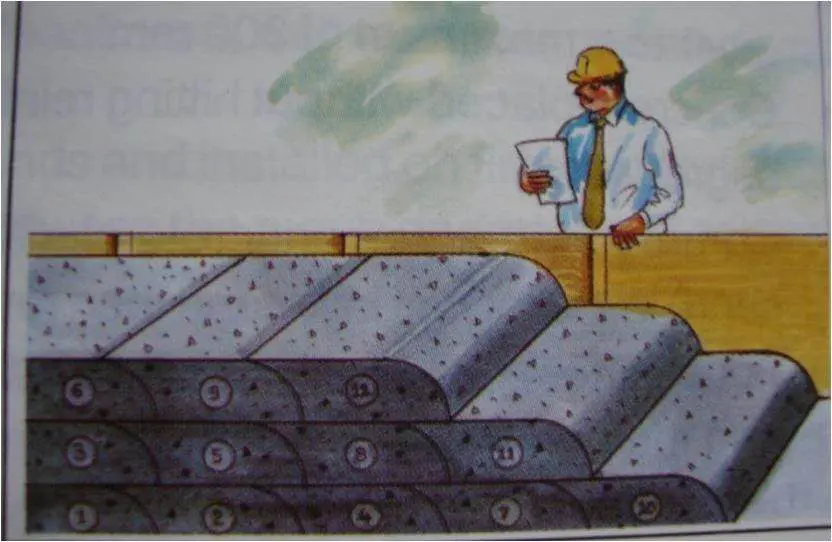

- Foundations to be concreted in layers of thickness not exceeding 300mm.

- Columns to be cast in one or maximum 2 lifts between the floors (window /opening provision to restrict concrete free fall to 1.5m), lift height not exceeding 3.0m for individual lifts.

- Slabs to be cast in strips and not in alternate bays. In slab construction, placing should be started along the perimeter at one end of the work with each batch placed against previously dispatched concrete.

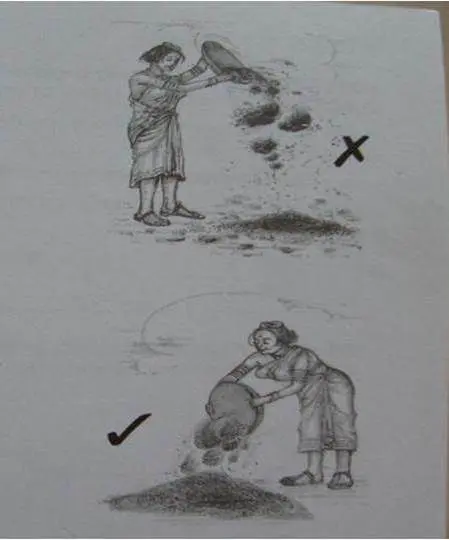

- Do not dump the concrete in separate piles and then level and work them together; nor should it be deposited in large piles and moved horizontally into final position.

- Construction joint locations should be approved (as shown in drawings)

- Items like insert, pipe sleeves, pipe, bolt & other fixtures should be provided as given in the good for construction drawing.

- All works should be true to level, plumb and square and all corners and edges in all cases should be unbroken & neat.

Step-2: Transportation & placing of concrete

- All concrete should be transported with the help of transit mixers to the place of laying as rapidly as possible.

- When a truck mixer or agitator is used for transporting concrete, the concrete should be delivered to the site of work and discharge should be complete within 2 hrs from plant exit.

- Acceptable temperature of concrete, air temperature & shade temperature etc. should be as per specifications and verified by supplier before delivery.

- Placing of concrete should generally be done using pumps to achieve necessary heights wherever required.

- In case of deep trenches/footings, it may be done with the help of chutes or directly from transit mixers from the reasonable height.

- In columns it can be placed manually with the help of staging. Concrete from wheel barrows should be dumped into the face of concrete already in place.

- Suitable platform should be provided for working wherever required.

- The concrete should be deposited as nearly as practicable in its final position to avoid re-handling.

- The concrete should be placed and compacted before initial setting of concrete commences and should not be subsequently disturbed.

- Concrete should be placed in layers. Bottom layer should not finally set before the top layers are placed.

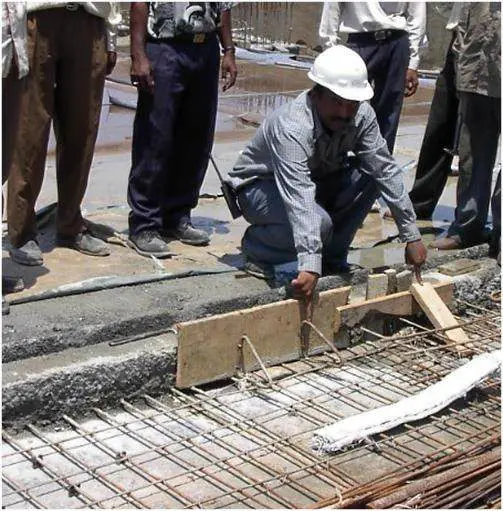

- Methods of placing should be such as to avoid segregation. Care should be taken to avoid displacement of reinforcement or movement of formwork.

- Formwork should be continuously watched during and after the concreting. In case of leakages, bulging or sagging immediate action should be taken before initial setting of the concrete.

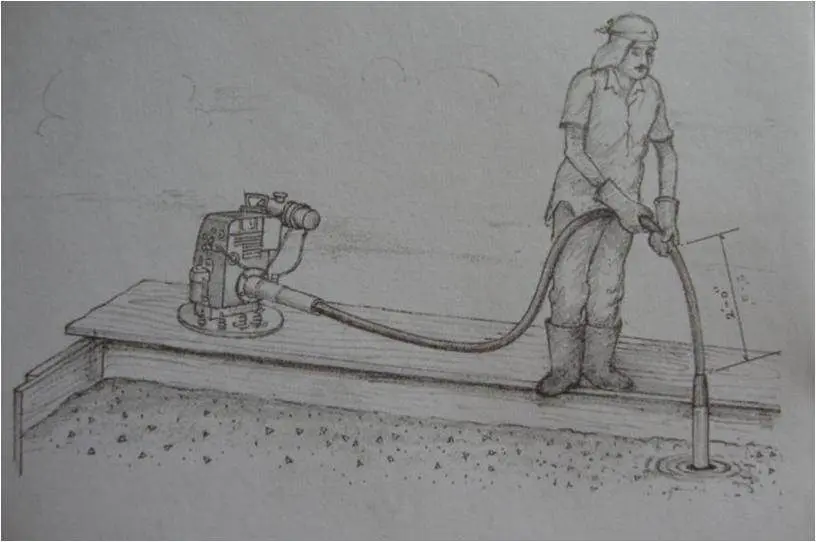

Step-3: Compaction of Concrete

- Concrete should be thoroughly compacted and fully worked around the reinforcement, around embedded fixtures and into corners of the formwork

- If no care is taken during vibration, it may result in honey combing. Remember 5 % Voids in Concrete, reduces strength of concrete by 30%

Precautions while placing and compacting concrete

- Don’t use a vibrator to move concrete horizontally.

- Don’t start a job without a spare vibrator.

- Concrete should not be over vibrated

- Stop vibrating concrete when the concrete surface takes on a shining appearance

- Stop vibrating concrete when larger air bubbles no longer escape

- Stop vibrating concrete when there is a change in the pitch or tone of the vibrator.

- Take extra precautions in locations of abrupt section change

- Set concrete not to be disturbed by successive vibration.

Points To Remember - Placing and Compacting Concrete

- Cube test cannot check degree of compaction achieved in-situ.

- Poor vibration may take all the difference between good and poor quality concrete.

- Vibration is a skilled job. Insist on a qualified operator. It will be good for the concrete and make the operator take pride in his work.

After Pouring Precautions!

Step-5: Finishing of Concrete

- Roof should be troweled even & smooth with wooden float before concrete begins to set.

- Surface that will receive plaster should be roughened immediately.

- Surface in contact with masonry should be roughened immediately.

- Surface that will receive floor finishes, tiling etc. should be roughened while it is still green.

- Freshly laid concrete should not be disturbed

- For ramps and basement concrete should be broom finished.

- After removal of formwork from vertical members the surface is checked for defects if any. All minor defects if appeared, to be rectified immediately.

- Hessian cloth should be wrapped on the surface of columns for curing.

- After 24 hrs of laying of concrete, the surfaces should be cured by either ponding or covering with moist Hessian cloth for period of 7 days.