Concrete, in itself, has poor tensile strength. To increase the tensile strength of concrete, steel reinforcement is used. Steel bars are embedded within the concrete mass. These steel bars carry most of the tensile load applied to the concrete.

The concrete renders the steel bars passive due to its highly alkaline nature, thus preventing them from corrosion. Still, due to various other reasons, the steel bars may get corroded over a long period of time. And due to the corrosion of the steel bars, various weaknesses arise in the concrete structure, which may eventually collapse if not taken proper care of within suitable time.

Corrosion of steel reinforcement bars is basically an electrochemical reaction. Small anodes and cathodes are created and a flow of ions between these two electrodes lead to the corrosion of the steel bars. There are two types of corrosion observed in the steel reinforcement bars:

- Crevice corrosion – In small crevices within the concrete structure, solutions may get stagnated. Anodes and cathodes may be created within the solutions due to uneven reaction of solute ions over the volume of the solution. Flow of ions is triggered by these electrodes, thus slowly causing corrosion.

- Pitting corrosion – It is related to de-passivation of small areas on the steel reinforcement bars. This type of corrosion is extremely localized and small holes or pits are created in the steel.

Causes of Corrosion in Reinforcement Steel

Corrosion of the steel reinforcement bars may occur due to localized failure of the passive film on the steel by chloride ions or a general failure of the passivity by neutralisation of the concrete due to reaction with carbon dioxide from the atmosphere. The main factors responsible for corrosion of reinforcement bars are:

- Loss of alkalinity due to carbonation – When the steel surface is left unprotected in the atmosphere, rust begins to form on the steel surface and gradually flakes off.

- Loss of alkalinity due to chlorides – Chloride ions tend to de-passivate the steel surface by destroying the alkalinity of the concrete.

- Cracks in concrete – Cracks may expose the steel bars to the atmosphere and hence increase carbonation.

- Moisture pathways – Regular wetting of the concrete may lead to water reaching the steel reinforcement bars by diffusion through the pore structure of the concrete or cracks present in the concrete. Rusting of the steel bars follow thereafter.

- Insufficient Cover: Insufficient dimension of concrete cover.

Corroded steel reinforcement possibly due to insufficient concrete cover

Effects of Corrosion on Steel Reinforcement

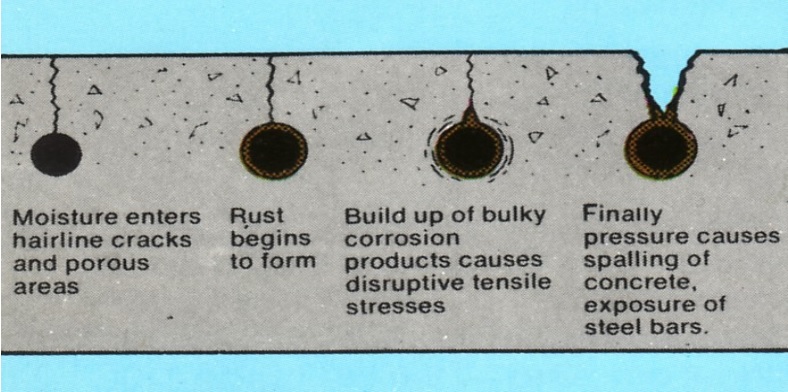

Once the steel bars start corroding, the reinforced concrete member gradually begins deteriorating going through the following stages:

- Formation of white patches – Atmospheric carbon dioxide reacts with calcium hydroxide present in the cement paste forming calcium carbonate. This calcium carbonate is carried by moisture and deposited onto the concrete surface forming white patches.

- Brown patches along reinforcement – When the steel bars start corroding, a layer of iron oxide is formed on it. This iron oxide also gets carried to the surface of the concrete by moisture.

- Formation of cracks – The products of corrosion occupy a greater volume than the original material. Hence they exert pressure on the concrete and crack it. With more corrosion occurring, more and wider cracks are formed.

- Spalling of concrete cover – Due to loss of the bond between concrete and steel, the concrete starts forming multiple layers of scales and peels off. The steel bars also get reduced in size.

- Snapping of bars – Due to reduction in the size of the steel bars, they finally snap. Also, there is a considerable reduction in the size of the main bars.

- Buckling of bars – Spalling of the concrete cover and snapping of bars lead to buckling of the main bars. This bulges the concrete in that region and eventually the whole structure collapses.

How to Avoid Corrosion of Steel Reinforcement

Corrosion of steel reinforcement bars may be prevented or at least delayed by practising good measures. Also, damaged steel bars can be repaired and the concrete structure can be restored properly. Some steps are given below:

- Providing Sufficient Concrete Cover: A good amount of concrete cover should be provided over the steel reinforcement bars. This ensures proper maintenance of the alkaline nature within the concrete and the passivity of the steel bars. The steel bars should be precisely placed in position

- Use of Good Quality Concrete: High quality concrete must be used. It helps to maintain proper alkaline nature. For the concrete, a water/cement ratio of 0.4 or less is to be maintained. Excessive water may damage the steel bars

- Proper Compaction fo Concrete: Concrete must be completely compacted such that there are no air voids or pockets present inside

- Use of FBE coated Bars: Fusion Bonded Epoxy Coating (FBEC) may be applied on the steel bars to prevent them from corrosion. Epoxy powder is spread electrostatically on to the steel bars. The powder melts and flows over the bars upon heating, forming a protective coating. They are thermoset polymer coatings because application of heat will not melt the coating. Apart from rebar it also has wide application in pipeline construction

- Use of Cement Based Polymers: Cement based polymers can be used in the concrete to enhance its protection against corrosion capabilities. The cement based polymers act as a binder in the concrete. They also increase the durability, tensile strength and vibration damping of the concrete

- RCPT test to assess degree of Corrosion: The Rapid Chloride Permeability Test (RCPT) may be performed to assess the degree of corrosion. The quantity of electrical current that passes through a sample 50 mm thick and 100 mm in diameter in 6 hours is measured. Based on this a qualitative rating is made of the permeability of the concrete

- Use of Migratory Corrosion Inhibitors: Migratory corrosion inhibitors may be used in the concrete mix or may be applied on the hardened surface of the concrete. These inhibitors diffuse through the concrete cover and reach the steel bars to protect them against corrosion. Calcium nitrite based inhibitors are quite common

– Vikram Agarwal

(+91) 7249196273

(+91) 7249196273