Laminated timber is the result of joining two boards to form a single unit, making the unit stronger and to add o to the strength. But, with the introduction of cross-laminated timber in 1990s, architects and engineers were enabled to design and construct tall structures using timber, with added advantages of resistance to fire and aesthetic appeal.

But with the advancing technology, laminated timber was just not restricted to one type; in fact, there were many new forms, types and varieties of laminated timbers that were produced and experimented with and now are under high-demand. These different types of mass timber have different uses and properties, making each one unique yet connected together.

1. Cross Laminated Timbers

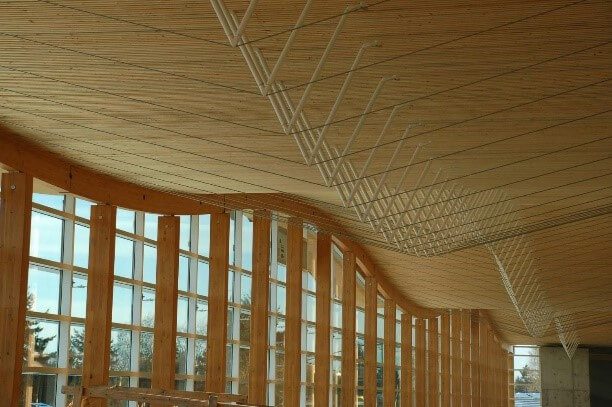

Cross-laminated timber was originally invented in Switzerland, but it was further developed in Austria in 1990s. Unlike the general laminated timber, for CLT, the stacking of boards is in perpendicular layers till desired thickness, which allows the construction of plates or surfaces like walls.

Generally there are three, five or seven layers, which after gluing are compressed and set to dry. It is basically a plywood made of boards that can reach enormous dimensions, 2.4 m to 4.0 m in height and up to 12.0 m in width.

Advantages of Cross Laminated timbers

- It is strong and stable and overcomes the inconsistences inherent in unmodified wood

- It requires lesser to no additional modifications when brought to site.

- Cost for materials and labour can be lower than traditional steel and concrete. The savings can range from 10%-15% more compared to concrete, steel and masonry.

- It requires a smaller foundation since CLT is lighter.

- Installation of prefabricated CLT pieces is faster.

- It is sustainable since wood is considered very environment-friendly due to its properties of renewability and reduced carbon impacts.

Disadvantages of Cross LamiNated Timbers

- Creation of wall cavities is limited hence there might be an increase in costs of electrical and plumbing services

- Since it is prefabricated, if the production site in not in close vicinity then there can be higher material transportation costs.

- Future renovations and changes are difficult.

2. Glue Laminated Timber (Gulam)

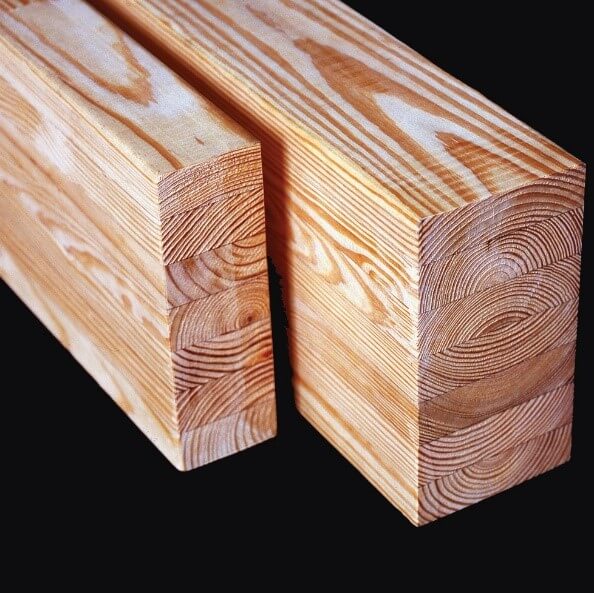

Often referred to as a high-tech building material of the future, Glulam is a versatile engineered wood that is known for its strength, aesthetics and reliability. It constitutes of several layers of timber bonded together using adhesives, in order to form a bigger and stronger piece of wood.

It is often specified as a viable replacement of structural concrete and steel. A lot of structural elements can be constructed out of glulam like parallel beams, pre-cambered beams, sloped beams, curved beams and even trusses.

Advantages of Glue Laminated Timber

- It is perfect for long span and curved designs.

- It offers strength with no compromise on aesthetics. Lamination process is quiet flexible and glulam of varied sizes ranging from 45 mm x 45 mm to 250 mm x 1800 mm x 30 mm can also be produced.

- It is locally available and environmentally sustainable material. Since it is constructed out of timber which is mostly available everywhere, it does not require mining or any other high energy demanding processes.

- It is far superior to solid timber due to its high strength and dimensional stability. Glulam members will remain more stable and will not form cracks unlike solid timber members.

Disadvantages of Glue Laminated Timber

- Prices compared to solid timber are higher

- Manufacturers tend to use sub-standard timber, which might cause defects later. Hence a proper and efficient check of the timber should be made.

- Due to the usage of glue, adhesives and other treating chemicals, which if not used properly, can cause the loss of natural look of the wood.

3. Nail laminated Timber (NLT)

Nail laminated timber (NLT), is a mass timber product constructed by turning dimensional lumbar on the edge and mechanically fastening the laminations together with nails. It is most commonly used for floor and roof systems.

The adjoining panels are laid in one direction and require support from beams or other structural elements. It can also be used for walls and elevator shafts. NLT can be fabricated on the project site or in a controlled environments.

Advantages of Nail Laminated Timber

- It delivers flexibility since it is relatively easy to fabricate it

- It is light weight compared to other materials used for floor and roof systems like concrete, steel etc.

- It can be used for both residential and commercial projects. It can achieve a variety of forms, including dramatic cantilevers, simple and compound curves etc.

- NLT with consistent cross section will allow sound waves to reflect similar to other hard-surface systems like concrete, CLT etc.

Disadvantages of nail Laminated Timber

- Once nailed completely and permanently, there is no possibility for rearrangement of timber panels. To make any possible changes, one has to use a saw leading to disfigurement of the actual constructed element.

4. Dowel Laminated Timber (DLT)

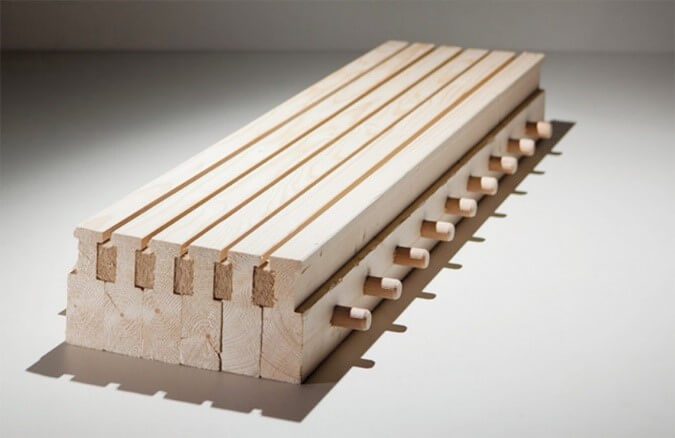

Dowel laminated timber or DLT is one of the most recent developments. ‘Dowel’ refers to the inclusion of wooden dowels, used to replace the nails or adhesives, making the laminated timber more flexible to changes and arrangements. The process includes inserting hardwood dowels into pre-drilled holes perpendicular to the posts or timber panels.

This system was designed to utilise a moisture content variation between the posts and dowels. Softwood posts are dried to moisture content of 12-15% and the hardwood dowels are dried to a moisture content of 8%. This property helps dowels lock themselves with the posts in order to maintain equilibrium of the moisture content.

Advantages of Dowel Laminated Timbers

- It is flexible in terms of attachment and construction. In order to make changes, dowels can be removed the posts can be rearranged.

- DLT members are more diverse and make up advanced structural applications and subsequently yield both environmental and economic benefits.

- It is very well suited for horizontal spans.

Disadvantages of Dowel Laminated Timbers

- Over time, hardwood fasteners or dowels lose their stiffness causing dimensional instability.

5. Laminated Veneer Lumbar

Laminated veneer lumbar of (LVL) is constructed by stacking of multiple layers of veneer, with grains running in same direction. It is used like glulam, for columns and beams. It stronger. Straighter and more uniform compared to lumbar. It can take greater stresses than glulam.

This high performance engineered hardwood permits beams and columns to have smaller cross sections than softwood glulam, thereby offering greater elegance to the timber structure.

Advantages of laminated veneer Lumbar

- The size of LVL is not limited by log size, due to its manufacturing method.

- LVL is one of the strongest wood-based construction materials relative to its density.

- Since it is manufactured with homogeneous quality that has minimum number of defects or even distribution of defects, mechanical properties of the final product can be predicted.

- LVL can be manufactured or customised in different shapes depending on its function.

Disadvantages of Laminated Veneer Lumbar

- Enhancement of strength properties of LVL by densification of veneer during the process is very limited.

- Although its dimensional stability is better than solid wood, the product may result in some defect such as warping, if not stored properly.

- LVL requires high capital investment to have relatively low production cost.

– Janvi Mangukiya

(+91) 7249196273

(+91) 7249196273