As the world is expanding so is the construction, as population increases and so is the construction for livelihood. But do you know how much energy one building consumes in construction? It’s a lot. Then can you imagine how much energy would all these constructions around us would be taking on a regular basis. Well we cannot stop construction because that is needed for livelihood, economically and for the development of the country. But what we can do is to use some green and eco friendly materials to at least reduce all these environmental effects to some extent.

Here we will see what is an ECOBRICK? Its manufacturing process and usage in our regular buildings. So, let us see some facts about it, its types and their construction methods below:-

Eco friendly Bricks

1. Bricks Made from Garbage

As the world is growing it is producing enough garbage as a living waste no matter how much we ignore it , or we dump it at the right place then make its garbage mountains , If it’s not recycled and used in the best way it will still be waste only. Garbage includes plastics, fabrics, wood and a lot of random materials. All of this is organic waste so we need to find a way to use this organic waste to turn it into something useful. This is done by a process called CONEX PROCESS that turns ecological garbage into bricks for construction. Let us understand the process of its manufacturing: –

- At first all the garbage is collected from the landfills and it goes to a hygiene process, and then all the recyclable materials like metal, are kept aside for further reuse and the rest is grounded until it become sand.

- Then this sand is mixed with con licks with enhance and inhabits its growth with bacteria’s the final compound is a clean compound that compiles with the microbiological standards of some standard companies and labs.

- Then this sand is mixed with soil and cement with red colour sometimes to give it a feel of brick and finally we have an ECOLOGICAL brick which is odourless and also double resistance power.

So, with this innovation the waste which looked of no use has been converted into a material which can be used in any construction process. Yes, you cannot use it in many high rises building but it can easily be used in a building till the height of 15 metres.

This conventional material is still underrated in our country and many others mainly because it takes time and energy to build. But if we start manufacturing and using it in our regular projects, we can contribute a lot for our environment with our benefits also as it is also cost effective. As you are using nothing but garbage as the raw material.

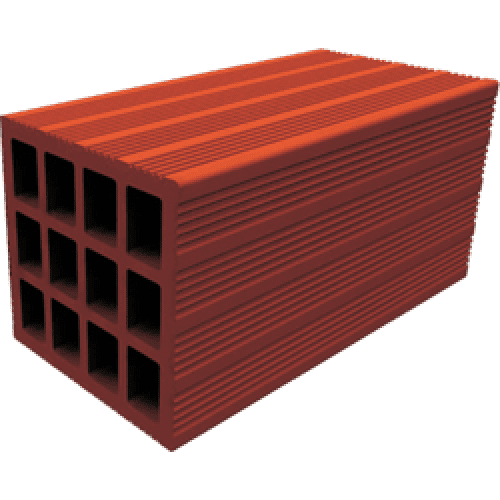

2. Porotherm Bricks

Another form of Eco brick that we can talk about is POROTHERM BRICKS now they are not necessarily eco bricks in terms of their manufacturing process but definitely in terms for their We know in India we have extreme climatic conditions and humidity so most part of our year either goes in humidity or in summers.

So, to keep our traditional homes cooler we eventually use artificial services like air conditioners but that is not only high on our pockets but also for they are bad for our enjoinment. So why not use a material that naturally cools down our building without any extra efforts by the user.

This is what POROTHERM BRICKS do when they are used in any building. Let us see how they works: –

- So, these are perforated clay bricks made with variety of natural materials like coal ash rice husk and some hard material granules, they are called POROTHERM because and are known only for their highly insulation properties.

- This brick facilitates thermal conditions in such a way that it keeps your home cooler in warm weather and warmer in cold seasons.

- They are made from natural materials away from any chemicals which makes them an eco-friendly solution for a better and greener environment.

Advantages of using Porotherm bricks

Now let us see some of its benefits in brief and why every architect or constructor should consider them using in their projects: –

- High strength – The best part about this brick is probably the strength it provides, as its manufacturing process involves high temperature, and also the use or terracotta gives it a great strength.

- Thermal power – It gives high level of thermal power and insulation due to the process of perforation which basically means giving small holes in between which let’s the air pass and also due to the absorption of moisture through those holes it gives desired result.

- Cost effective – Not just in energy saving but these bricks are also good at cost saving as when you have a home or building build with this brick you won’t feel the need to have A.C in summer and heater in winter. It does not even require any sand or cement to get laid on the walls also its maintenance free. All of this makes it a big cost saviour.

- Construction speed – When using this brick in any building construction speed also get high as these are light weight, ease of handling and eliminates the curing time since sand and cement are not used in construction with porotherm bricks for walls.Also, they can be easily cut and chisel which makes fixture installation easier.

Finally, these bricks when used maintain a dry and clean site work as they do not leave any debris to dispose. They can also be used in load bearing or non-load bearing walls as well. The only disadvantage is they cannot be used in very high-rise structures due to less density.

The last thing to be known is they can only be used in wall construction and not foundation or any other structure part as their sole purpose is to provide insulation to the wall for a comfortable inside temperature.

– Asmita Madan