What is Ferro cement?

Ferro Cement (also called Ferro-concrete) is a rich or composite mortar plaster applied to both sides of a thin and well distributed reinforcement layer (usually a layer metal mesh and closely spaced thin steel rods). Normally plaster of 1:2 cement mortar should be applied to a matrix structure made of weld mesh would round the chicken mesh.

Ferro cement componets have high strength as the cement content is very high (i.e, in the orders of 700 kg/m3). Since the steel is spread over the area, the ferro cement components are usually a homegenious in composition.

Ferro cement is applied with pressure over the weld chicken mesh matrix. The mortar holds in position because of the mechanical interlocking. So No shuttering is required to cast ferrocement components.

Since Ferrocements are made of mortar with higher cement content, the chances of shrinkage cracks are high. Ferrocement components are to be cured for a minimum period of 7 days without interruption to avoid any shrinkage cracks.

application of Ferrocement

- Used in making boats

- Used as planks for shelves in housing projects replacing costly wooden planks

- Used in construction of boxes for water and electrical meters

- Used in construction of sewage manhole covers

- Ferro-cement components are Used in Rural areas for low cost housing

- Recently Ferro-cements are used in some residential and industrial buildings also

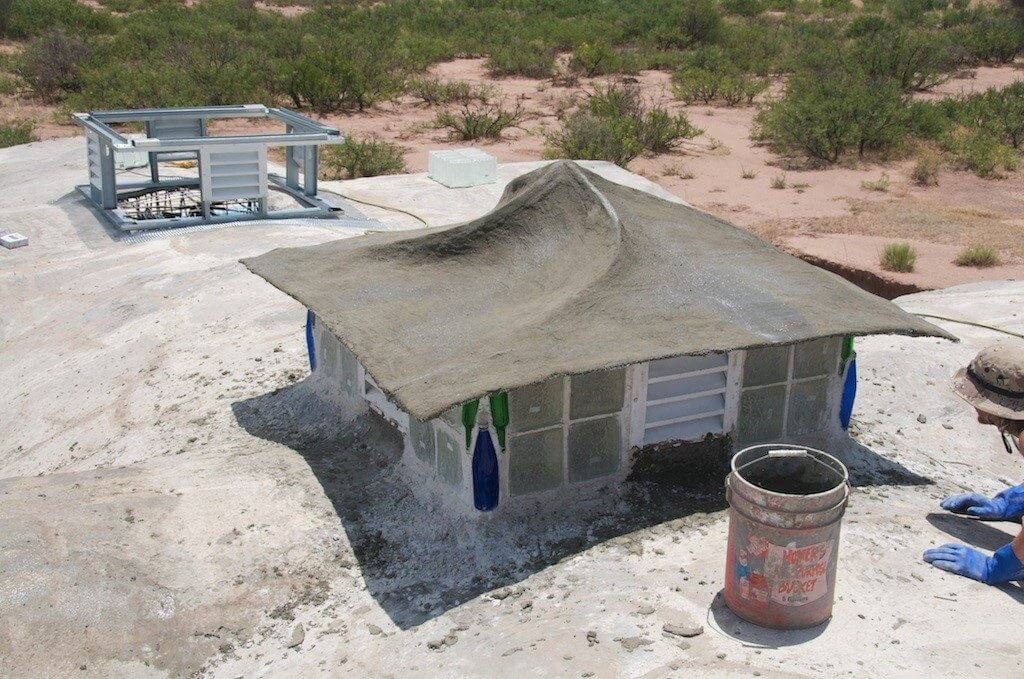

Roof Constructed Out of Ferro Cement

Advantages of Using Ferrocement

- Raw materials required for Ferrocement construction are easily available

- The fabrication of the mesh can be done in many shapes that suits the requirements

- Ferrocements are more durable and are cheaper than steel and wood

- Application of Ferro-cement doesn’t require any heavy machinery

Disadvantages of Using Ferrocement

- Excessive shrinkage due to higher cement content. Needs constant curing for a period of 7 days to avoid any shrinkage cracks

- Prone to corrosion of MS rods and GI mesh due to incomplete coverge of materials by mortar

- Ferro-cement is labour intensive. So it might not be economical to use ferrocements in places where the labour costs are high

- As ferro-cement components are usually thin structures, Buckling is another factor that needs to be taken into consideration during

(+91) 7249196273

(+91) 7249196273