Geogrid is a polymeric material made up of many polymers like polyethylene, polyvinyl alcohol polypropylene etc. It is one of the most important inventions in geosynthesis which is used as a reinforcing material. They formed by joining intersecting ribs. They have large open spaces in between the ribs known as “apertures”.

Manufacture of Geo-grids:

The manufacturing of geogrids commercially is carried out by three ways which is explained below,

- By Extrusion: In this method a flat polymeric sheet of material is made into a geogrid by extrusion and holes of desired dimensions are punched in the flat sheet to form the apertures. Then stretching is done to impart the tensile strength.

- By Weaving or Knitting: As the name signifies the geogrids are manufactured by weaving fibrous yarns and apertures are formed in between the flexible joints. These types of geogrids have high tenacity.

- By Welding and Extrusion: This method is similar to that of extrusion, only difference is that the extrusion of ribs is carried out by passing it through rollers, then they are sent to the welding section to form apertures. This method makes use of automated machines

Types of Geogrids

Geogrids can be classified into two types based on the stress transfer or direction of stretching during manufacture as

1. Type of Geogrid based on Pattern

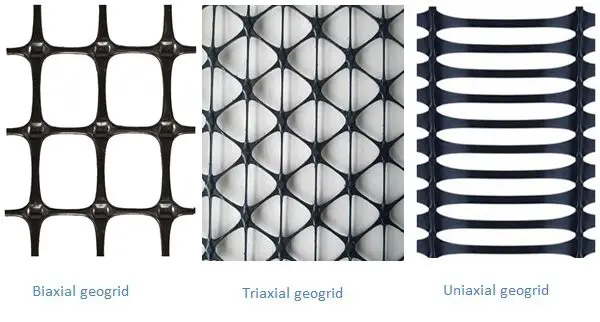

- Uniaxial geogrid – It is stretched only along longitudinal direction. Thus the stress is transferred only along that axis; even the tensile strength is more in longitudinal direction when compared to transverse direction in uniaxial geogrids.

- Biaxial geogrid – It is stretched along two directions (longitudinal and transverse), thus the stress is equally distributed along both directions. In biaxial geogrids the longitudinal direction is called as machine direction (MD) and transverse direction is called cross machine direction (CMD). Since the strength is equal along both axis these geogrids are mostly preferred in construction.

- Triaxial geogrids are also available.

2. Types of Geogrid based on Manufacturing

Geogrids also have another classification based on the method of manufacturing, they are

- Extruded geogrid

- Woven geogrid

- Bonded geogrid

Working of Geogrid

Geogrids work by interlocking with the granular or fine material placed over them. The apertures allow for strike-through of the cover soil material which then interlocks with the ribs (flat straps/bars) providing confinement of the overlaying granular/soil material due to the stiffness and strength of the ribs.

Working of Geogrids by Interlocking the Granular Material

Physical and Mechanical Properties of Biaxial Grid

Component Description Unit

- Tensile strength at 2% Strain 14 KN-m.

- Tensile strength at 5% Strain 28 KNm.

- Maximum tensile strength: MD/CMD 40 = 40 KN-m.

- Elongation at nominal strength: MD/CMD 11 = 10 KN-m.

Note: MD = machine direction; CMD =cross machine direction.

Application of Geogrids

Geogrids in earlier days was only used for the construction of retaining walls.it was found very adaptable in retaining walls because of its highly flexible nature which makes the retaining wall more stable and earthquake resistant. And also the cost of construction was found to be considerably reduced when geogrids we used compared to conventional concrete retaining walls.

Geogrids in retaining wall

The advantages of geogrid in retaining wall resulted in the further use of geogrids in many structures like pavements, dams etc. and it was found very much suitable due its property of redistributing load over a wider area, high tensile strength, holding capacity, environmental friendly properties.

Geogrids in pavement construction and to stabilize railway tracks

Research is being carried out to check the compatibility of geogrids in concrete pavements since it can increase the durability of rigid pavements with its high flexural strength obtained when combined with concrete.

Geogrids are also used to stabilize the subgrade for construction of embankments in highways, railways and also in the stabilization of soil with low bearing strength or high water table levels where laying of foundation to carry heavy loads becomes critical.

Advantages of Geogrids:

- The use of geogrids results in a more economical construction.

- It is environmental friendly.

- Imparting geogrids makes the members more durable since it resists environmental attacks.

- It prevents the soil from erosion.

- Geogrids ensure ease of construction as the placement techniques are simple.

Thus by the above mentioned applications and benefits, it is seen that the use of geogrids will result in a sustainable development in the construction industry.