High Strength Concrete

High strength concrete as the name signifies is concrete having compressive strength more than 40MPa. Nowadays due to high technological development it is possible to obtain concrete strengths of about 150MPa, thus only strengths above 60MPa are recognised as high strength concrete in recent days. Compressive strength is the most important characteristic which is considered to state whether the concrete is suitable for construction or not, though other properties like tensile and flexural strength are being tested for, compressive strength holds prime importance in the construction industry. Hence with higher compressive strengths the concrete becomes more desirable.

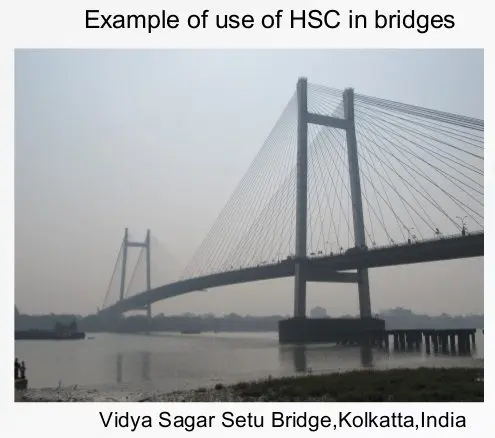

High strength concrete has found its invaluable position in the construction of

- High rise buildings.

- Bridges with long spans.

- High load carrying buildings built on weak soil ( low bearing capacity)

To achieve this high strengths the water cement ratio must be as low as possible, but lowering the water content will result in less workable concrete. Thus more compaction is required while placing this type of concrete to avoid segregation and honey combs.

The addition of super plasticizers can also be implied to increase the workability for the desired water content or decrease the water content for the desired workability.

Mineral admixtures like fly ash and silica fume are also used in high strength concrete to increase the compressive strength. Materials like silica fume being a very fine powder of size in microns with cementitious properties binds well with cement to produce a stiff mix with high strengths of the order of 80MPa or more.

Advantages of High Strength Concrete

The advantages of high strength concrete:

- Reduced maintenance and repair.

- The size of structural members like beams and columns are reduced since smaller sections are enough to carry high loads.

- Since the size of members are reduced the cost of formworks are less.

- In bridge construction the use of high strength concrete becomes inevitable because longer spans with minimum supports can be constructed.

- Construction of slabs and floors with thinner sections is made possible.

mix design procedure for High Strength Concrete

The mix design of high strength concrete is similar to conventional concrete with minor variations because the volume of mineral admixtures is calculated too. It can be done by two methods IS code method and ACI method. The design procedure explained below is based on ACI method

- Determination of mean design strength based on the required concrete strength.

- Determination of optimum coarse aggregate content based on nominal size of coarse aggregate required.

- Estimation of the water content required.

- Selection of water cement ratio from the table based on the field strength and maximum size of coarse aggregate.

- Calculation of cement content based on the water cement ratio.

- Providing the required adjustments in the mix based on the admixtures used.

High Performance Concrete

High performance concrete is a concrete having high strength, high durability, high resistance to chemical attack and high workability. In other words all the mechanical properties of concrete are superior in a high performance concrete.

Though strength has been the major concern in a concrete mix, gradually the importance of durability and workability was realised in the long run which lead to the invention of high performance concrete.

American Concrete Institute defines High Performance Concrete as “A concrete which meets special performance and uniformity requirements that cannot always be achieved routinely by using only conventional materials and normal mixing, placing and curing practices”

The use of high performance concrete has overcome many problems observed in conventional concrete like less durability, weaker transition zone ( aggregate-cement interface), low resistance to chemical attack and difficulty in repair and retrofitting works.

Material Consideration for High Performance Concrete

- The materials used in high performance concrete are nothing different from the conventional concrete, only that the mineral admixtures like silica fume, granulated blast furnace slag and fly ash are used in higher concentrations. Care is to be taken during the mix design to maintain appropriate quantities of these admixtures and other materials within the permissible limits to achieve the properties of HPC.

- Cement with lower percentage of tricalcium aluminate C3A is required to make HPC

- When aggregates are concerned coarse sand can be used as fine aggregate to reduce the water content since more fine particles like silica fume are to be used which will increase the water demand.

- And coarse aggregate nature plays an important role in the properties of HPC. Stronger the coarse aggregate, stronger will be the aggregate cement interface (transition zone) thus resulting in high performance. Mostly well graded cubic aggregates are preferred.

- Chemical admixtures like super plasticizers, retarders and air entraining agents are used in HPC to have better workability (mobility) at lower water contents.

Advantages and Application of HPC

The advantages of high performance concrete are

- Reduced maintenance cost — though the initial cost of HPC is high when compared to conventional concrete, since less maintenance is required it results to be more economical.

- The service life of a structure is more since the concrete is more durable and resist abrasion and chemical attack.

- As a result of high strength the size of structural members is reduced.

On the account of its superior mechanical properties, HPC finds its application in various types of structures like

- High rise buildings

- Tunnels

- Bridges with long spans.

- Nuclear structures

- Constructions at sever exposure conditions

Joigny Bridge Built Using High Performance Concrete

mix design Procedure for High Performance Concrete

The steps involved in the mix design of high performance concrete is given below

- Based on the rheological properties (e.g. Workability) and compressive strength desired, the yield stress and plastic velocity is determined

- The dosage of high range water reducers (HRWR) used to reduce the water content is determined, usually it is 1.5% of the weight of cement

- Sand content required is determined from code as per zones of construction

- Coarse aggregate content required is calculated per m3 of concrete

- Cement content based on the water cement ratio is calculated.

- Finally correction factors are applied based on IS CODE 10262.

Abbreviations Used:

HPC – High performance concrete

HRWR- High range water reducers

– Hemalatha Sekar