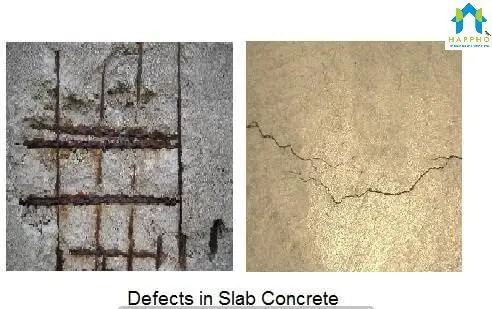

Most buildings in India, whether they are residential or commercial, suffer from cracks and consequently leakages in their slabs. In most of the cases these issues occur within 15 years after their construction, this is less than one-fourth of the design life of the structure. Defects like cracks in the slab, when neglected at the time of construction, can result in heavy repair / maintenance costs in the long run. These cracks provide a point of entry for the water and the aggressive chemicals dissolved in this water to enter the slab, and cause such problems. Cracking in concrete is caused due to

- Improper design of concrete mix.

- Improper placing practises of concrete.

- Drying and shrinkage cracks of fresh concrete

- Cracking due to – intrinsic sulphate attack, alkali-aggregate reaction and incompatibility of different concrete ingredients.

- Cyclic loading and alternate wetting/drying (weathering action)

For constructing the slab, both selection of right materials and use of best practices plays an important role in determining the durability achieved by concrete.

Different criteria for maximum durability are:

Criteria for Achieving Maximum Durability of RCC:

1. How to Select Right Quality Cement for Slab?

- The cement used should have low heat of hydration and after setting it should be water-tight (impermeable).

- The cement which is favourable considering the above aspects is PPC (Portland Pozzolana Cement). PPC should be used when sufficient time is available for construction. Because the slab using concrete containing PPC has a slow rate of strength gain, in comparison to OPC. Since PPC is Grade 33, a higher cement content is required for achieving same strength as OPC. So, Design mix should be adopted preferably when using PPC.

- If the time is unavailable and the formwork needs to be reused within a shorter time period, then OPC 53 is the best cement. Using best practices of construction, OPC 53 grade cement can be an economical option both in terms of saving time and amount of cement used in concrete.

2. How to select the right quality of Aggregates for Slab?

- The gradation of aggregates (percentage proportions of various sizes) should be satisfactory so as to minimise voids and maximize density and compressive strength. This also affects workability.

- Usually coarse aggregates of 20 mm nominal size are used, as they are easily available and they are usually smaller than one-fifth of the depth of the slab. Coarse aggregate of 10 mm size is used along with 20mm for better packing density, so as to minimise voids and maximize density and compressive strength.

- The maximum total amount of deleterious materials allowed is 5 percent. The fine aggregates should not contain salts. River sand should have low silt content, less than 3% by weight, the fineness modulus to be in the range of 2.6 – 3.0.

3. How to batch and Mix Concrete for Slab?

- At general sites, Cement is batched by its weight or the number of bags of cement (each bag contains 50 kg of cement). The aggregates are batched by volume, and hence the amount of water present in them and the bulking of sand should be taken into account.

- The moisture content of aggregates should be tested as frequently as possible, so as to maintain the water-cement ratio constant. Contractors usually add Additional amount of water for increasing workability. This should be avoided as it decreases strength and density of the concrete.

- Use chemical admixture to reduce water requirement in concrete to achieve ease of placing (workability).

4. how to Choose Right Formwork for Slab Casting?

- The formwork has the function of a mould for freshly produced/placed concrete, so that it can harden and attain the desired shape. It should remain rigid while placing and compacting the concrete.

- The formwork should be water-tight to prevent loss of cement slurry, as it results in decrease in cement and water content. It also leads to honeycombing of concrete. Brown tape needs to be affixed at plate joints to make it water-tight.

- The formwork should be fitted with connections and props in such a manner that they can be removed with ease and reused with minimum repairs to them.

- The faces of the formwork in contact with the concrete should be cleaned and treated with form release agent so as to form a thin uniform coating.

5. How to Choose Quality Reinforcement for Slab?

- The reinforcement should be tied properly to minimise the movement of re-bars and the binding ties should not protrude into the cover region /zone.

- The spacing between successive re-bars should be maintained and the alternate bars should be extended 0.3 times the span to the adjacent slab.

- The lower reinforcement mat is supported on cover blocks and the upper reinforcement mat is supported using steel chairs and edge U-bars.

- The laps in different bars should be staggered and the lap length should be as prescribed in IS 456 – 2000

6. how to do Waterproofing the Slab While Casting?

- Integral waterproofing for terrace slabs can be carried about by mixing waterproofing admixtures in the concrete before placing. Integral Water proofing admixtures are of two types – crystalline, hydrophobic & powdered/filler. These admixtures reduce the porosity of the concrete.

7. Placing of Concrete / Casting of Slab Properly

- The casting of the slab should be scheduled on a rain-free day. Concreting should be avoided at all circumstances when it the weather is extremely hot or extremely cold.

- The freshly casted slab should be covered with moist gunny bags, after 4-5 hours, in case of concreting in summer to avoid plastic shrinkage cracks. Start curing as soon as feasible.

- The concrete shall be poured only after making sure that the formwork is in line, level and re-bars are tied properly and proper spacing is maintained between re-bars.

- The electrical and plumbing conduits/pipes should be laid and should be checked for leakages, before the casting of the slab. The pluming fittings like elbows, bends, etc. should be choked with gunny bags to prevent the entry of concrete into the pipes.

- Placing should be started along the perimeter at one end of the slab, with each batch placed against the previously placed batch, never delay placing of concrete batched beyond the initial setting time of concrete (~90 min.)

- The concrete should not be dumped in separate piles and then levelled and worked. It should not be dumped in large piles and moved/spread horizontally to its final position.

- The concrete should not be allowed to free fall from a height more than 1.5 meters.

- The formwork should be constantly monitored till the concreting is completed, so as to spot and leakages of slurry or if the formwork is displaced due to the weight of the concrete or compaction process.

8. How to Compact Slab Properly

- The concrete should be compacted so as to mould it around the reinforcement within the formwork to eliminate large voids, honeycombs and entrapped air. This results in maximum density and minimum voids, which ensures high compressive strength

- The most commonly used compacting equipment are vibrators, either internal (needle type) or external (screed/pan type).

- Special care should be taken to make sure compaction is properly carried out at the edges & corners.

9. How to Finish the Surface of Slab?

- The surface of the poured concrete should be finished using a wooden float or rake, as close as possible to its final plane. This should be done after excess concrete has been removed and the surface has been levelled using a screed.

- Adequate sloping (generally 1 in 45) should be ensured, if it’s a terrace slab, to facilitate drainage of rainwater. The valleys should be checked for leakages after the concrete has set and should be filled with grout in the construction phase itself.

- If there is bleed water (water which accumulates at the surface), then the surface should not be finished, let water get evaporated before finishing. Check concrete mix if excess bleeding is observed.

10. How to Cure Slab Concrete?

- Curing can be done either by ponding or using membranes, it should be carried for 7-10 days.

- Ponding is the best method of curing. The slab is divide divided into smaller rectangular areas using mortar or clay, and these small ponds are filled with water. This method of curing requires a large amount of water. Curing should be started 24 hours after casting of concrete.

- Membrane curing can be adopted in regions where water is scarce. The membrane is a waterproof material which is used to cover the slab, which prevents the evaporation of water.

11. Miscellaneous Things to Keep in Mind

- The slab should not be overloaded with piles of construction materials after it has been cast. This should be avoided till 28 days from the day of casting of slab.

- Honeycombs (If any) should be finished with polymer modified repair mortar.

- De-shuttering of slab should be done 7-10 days or more after casting the slab depending upon the span and the type of cement used.

- The formation of cold joints in the slabs should be avoided, never delay placing of concrete batched beyond the initial setting time of concrete (~90 min.)