What are Chemical Admixtures?

Admixtures are material other than cement, aggregates & water that are added to concrete either before or during mixing to alter its properties & performance in fresh (workability, setting time etc.) and hardened state (strength, durability etc.)

Concrete admixtures are broadly divided into two type’s i.e. chemical and mineral admixture.

Chemical admixture are incorporated to modify the properties of concrete such as heat of hydration, accelerate or retard the setting time, improve workability, help in water reduction ,disperse/deflocculates the cement particles, aid in entrain air and finally improve the impermeability and durability characteristics.

Importance of Chemical admxitures

Chemical Admixtures are added to improve or alter the following concrete properties

- Protect Against Freeze Thaw Cycles –Improve Durability

- Mid- Range water reducers

- High-Range water reducers – superplasticizers

- High Strength Concrete

- Corrosion Protection

- Set Acceleration

- Strength Enhancement

- Set Retardation

- Crack Control (shrinkage reduction)

- Flowability

- Self levelling

- Finish Enhancement

Chemical admixtures are used to improve the quality of concrete during mixing, transporting, placement and curing. They reduce the cost of construction, modify properties of hardened concrete, ensure quality of concrete during mixing/transporting/placing/curing, and overcome certain emergencies during concrete operations.

They are basically chemical compounds. Dosage ranges from 0.2% to 2% by weight of cement.

Types of Chemical Admixtures

Chemical Retarders can be classified into the following types:

- Air Entrainers

- Water Reducers

- Set Retarders

- Set Accelerators

- Superplasticizers

- Specialty Admixtures

- Air entrainers

Air-entraining agents entrain small air bubbles in the concrete. The major benefit of this is enhanced durability in freeze-thaw cycles, especially relevant in cold climates.

- Water reducers

Water reducing admixtures require less water to make a concrete of equal slump, or increase the slump of concrete at the same water content. Typical water reduction is the range of 10 – 15%.

- Set retarders

Retarding admixtures slow down the hydration of cement, lengthening set time. Retarders are beneficially used in hot weather conditions in order to overcome accelerating effects of higher temperatures and large masses of concrete on concrete setting time. If concrete batching and placing location are far apart set retarders are very useful too exted initial setting time of concrete.

- Set accelerators

Accelerators shorten the set time of concrete, allowing a cold-weather pour, early removal of forms, early surface finishing, and in some cases, early load application. For repair and retrofitting works too set accelerators are boon.

- Superplasticizers

High range water reducers are admixtures that allow large water reduction or greater flowability (as defined by the manufacturers, concrete suppliers and industry standards) without substantially slowing set time or increasing air entrainment. Superplasticisers are integral part of a high strength concrete.

- Specialty admixtures: which include corrosion inhibitors, shrinkage control, alkali-silica reactivity inhibitors, and coloring.

Role of Water Reducing Admixtures (Normal/High range) in Concrete

Option-1: Reasons for using a Water Reducer

- To get a stronger and more durable concrete from a given amount of cement by allowing reduction of water-cement ratio

- Most regular water reducers will permit 5-15% reduction water

Example

- Original mix:

330 kg cement, 181.5 kg water, w/c = 0.55 ; strength at 28 days = 30 MPa

- Mix with water reducer

330 kg cement, 165 kg water, w/c = 0.5 ; strength at 28 days = 36 MPa

High strength is achieved at same cement content.

Option-2: Reasons for Using Water Reducer

Making unworkable mix workable

- For a given w/c mix may turn out to be unworkable

Add water reducer to increase slump without making adjustment to mix proportions.

Results in better compactibility of the mix and strength increase slightly

Economy: a concrete with the same w/c and same strength can be produced with less cement.

Normally the extra cost for the water reducer is more than offset by savings in cement.

Example

Original Mix -330 kg cement, 165 kg water, w/c =0.5

Mix with WR (10% water reduction).

150 kg water, For w/c = 0.5, cement required = 300 kg, Save 30 kg cement/m 3

Terms associated with the interaction of chemical admixture and cementitious system:

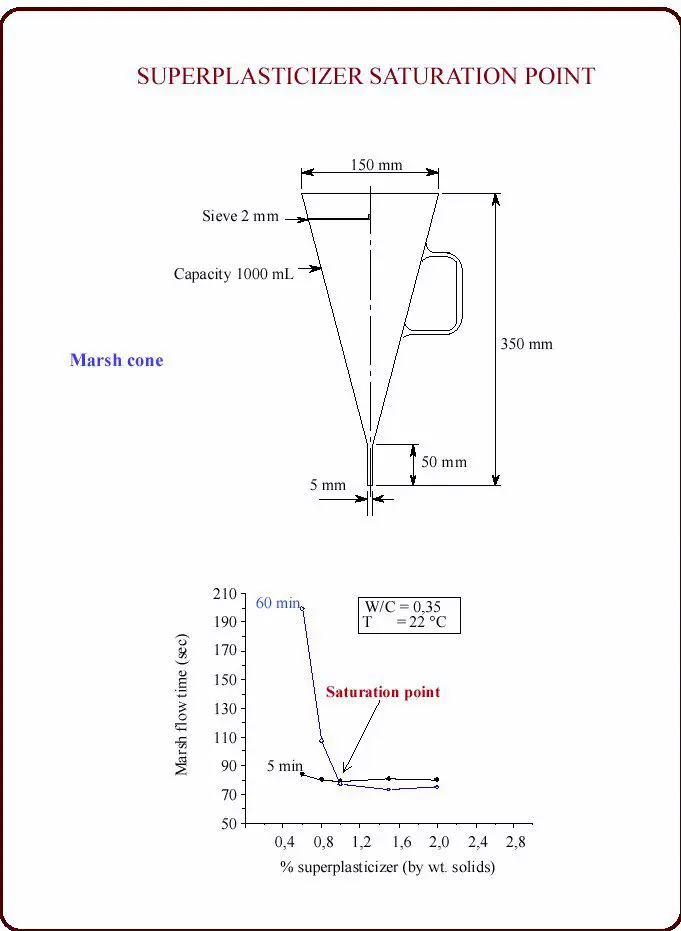

- Saturation point :Saturation dosage of a given HRWRA (High Range water reducing admixture) exists for each cementitious system. Beyond this dosage any additional increase does not generate any increase in fluidity of the cement paste and the increase slump of concrete.

- Incompatibility : A rapid loss is sometime observed in superplasticized concrete, although the saturation dosage has been used, in this case the cement and HRWRA are said to be incompatible.

- Compatibility : When a high slump can be maintained for a longer period of time, without any significant segregation and bleeding, the HRWRA are said to be compatible.

- Robustness: When a little variation in the composition of one of the ingredient of the mix does not lead to a big variation of the properties of the concrete.

Issues related to addition of Chemical Admixtures in Concrete

Compatibility and Robostness

Compatibility and robustness are the two main issues governing the choice of chemical admixture in cementitious systems, to achieve the intended concrete properties.

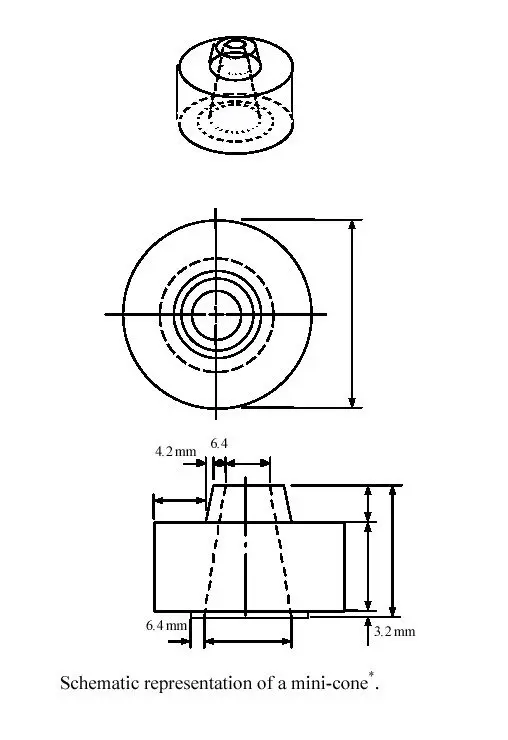

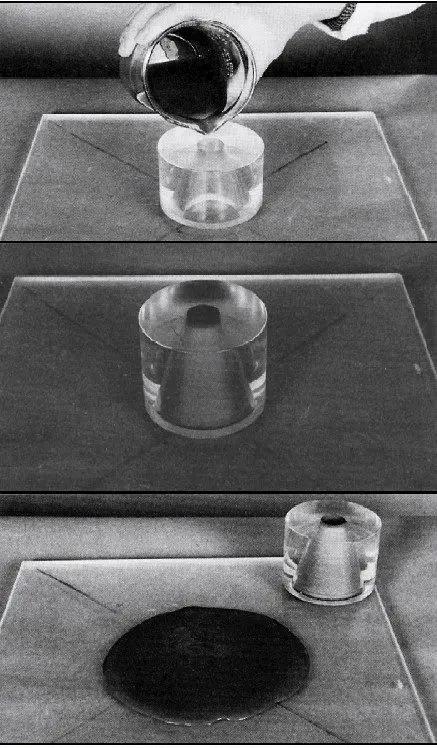

- Simple tests on grouts, such as Marsh Cone test or Mini- slump cone test can give a fair idea of compatibility between chemical admixture and cementitious system.

- Fewer trials concrete mixture may be needed to obtain an optimized concrete mixture, once above test on grouts are performed.

Mini Slump Cone

Key Factors governing chemical admixture and cementitious system compatibility:

Key Factors governing chemical admixture and cementitious system compatibility:

- Chemical & phase compositions of cement especially C3A & alikali.

- Cement fineness.

- Amount and type of Gypsum

- Chemical & Average molecular weight of admixture.

- Dosage of Admixture & addition method.

- Degree of sulphonation, purity.

Type and quantity of mineral admixture present in the concrete also plays critical role.

Concluding Remarks

Chemical Admixture play a very important role in concrete, its judicious selection improves its fresh and hardened concrete properties & enhances its long terms performance.

New age concrete like Self Compacting Concrete, High Volume Fly Ash Concrete, High Performance Concrete etc, would not have been realized without the availability / incorporation of chemical admixture.

Mandatory use of chemical admixture should be encouraged in order to attain true sustainable development.