Waterproofing in buildings is the process of making a structure impervious to water. It is one of the most critical part of building construction.

Where do Leakages generally Occur?

- Basement of structure

- Walls

- Bathrooms and kitchen

- Balconies, decks

- Terrace or roofs

- Green roofs

- Water tanks

- Swimming pools

There are many causes and locations of leakages in a building. Broken pipes, hoses, improper construction and waterproofing, structural cracks and several such issues are major causes of leakages. It is necessary to have a leak-proof and damp-proof building to avoid losses and harm to our health.

Why Do Leakages harm Us?

Leakages can cause dampness and this in turn encourages the growth of molds, microbes, and many other organisms which could be harmful to us. Asthma and allergy are some common respiratory disorders that are causes by these problems.

Apart from health issues, leakages can cause issues like flaking and blistering of paints, cracking of structures, etc. This can harm its users and also lead to depreciation of the property value.

Dampness in buildings can cause several respiratory disorders

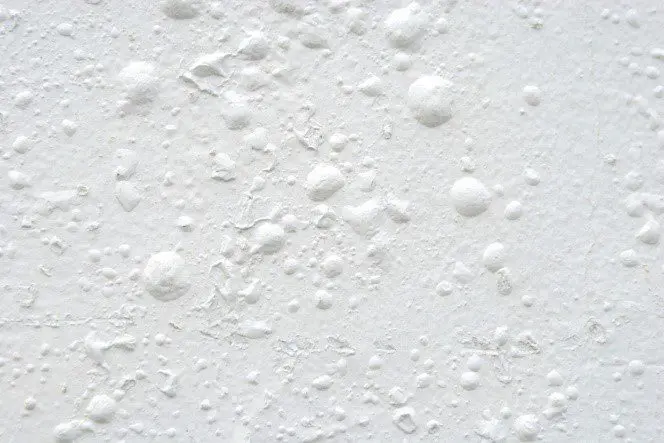

Mold growth on walls due to dampness

Leakages may cause dampness which in turn may cause flaking and blistering of paint

How Can We Make a Building Water Resistant?

- Some of the commonly used methods for waterproofing are:

- Cementitious waterproofing

- Liquid membrane method

- Bituminous membranes and coating methods

- Polyurethane liquid membrane method

1. Cementitious Waterproofing

Cementitious waterproofing in toilet

It is the simplest form of waterproofing. The products required for this are easily available in the market. Cementitious method is used for internal wet areas such as toilets which are not exposed to sunlight and weathering. In this method, a mixture of dry cement, sand, and liquid latex are applied over the surfaces using brush or roller

2. Liquid Membrane Method

Primer coating process

The membrane used consists of a primer coat and two top coats applied using spray, roller or trowel. The liquid cures into a rubbery coating on the surface. It it generally composed of polymer-modified asphalt. Various grades of this are available by different manufacturers depending on whether the membrane is going to be trowelled, rolled or sprayed.

3. Bituminous Membranes and Coating Methods

Bituminous emulsion being applied

Bitumen a.k.a. Asphalt and bituminous substances have been popular waterproofing solutions. Bitumen is a thick organic liquid which can be applied on required surfaces to make them waterproof. This method is excellent with concrete structures but should not be exposed to sunlight. Sun-exposure makes it brittle and fragile.

Bituminous membrane rolls

Bituminous membranes are generally used for low-sloped roofs. Resins and oils are added to bituminous membranes to increase adhesiveness. The membranes come in the form of rolls 2-4mm thick, which are later unfolded and laid on required surfaces. Inflammable materials should not be in their vicinity to avoid fire accidents.

4. polyurethene Liquid Memberane Method

This method is generally used for flat roof areas and other weathering-prone surfaces. The membranes can be clear or pigmented Aliphatic Polyurethane. It is a two-pack system consisting of a pigment and solvent which are mixed in definite ratios before applying on the required areas. This method offers high flexibility in terms of application.