Laminate is a hard and brittle sheets having thickness around 1mm used to overlay on wooden furniture. Laminates are the most affordable materials in the market and comes in various colours and patterns that gives furniture more fine and attractive look. They are usually water resistant, abrasion resistant and scratch resistant.

Laminates can be used to decorate your kitchen cabinets, furniture like wardrobes etc., and laboratory surfaces. Laminate sheets are available in market in 8 feet X 4 feet. The thickness of laminate generally thickness is vary from 0.6mm to 1.5mm.

Laminate sheets are available in different size, pattern, colors and textures.

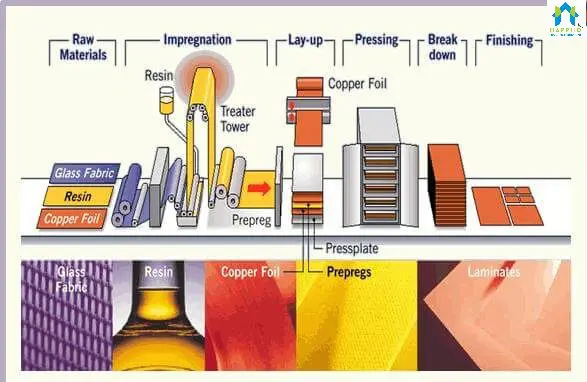

Step By Step Manufacturing Process of Decorative laminates

Step-1: Saturating Laminate Paper

The back of laminate is generally made up of craft paper. This craft paper first drenches in resin containing phenol (a compound derived from Benzene) . This paper absorb phenol and form saturated layer on surface. The paper is then dried in a drying oven where hot air cures the paper. The paper in then would into a roll.

After this a top layer of laminate which is called decorative layer is prepared.

The manufacturing process for a printed or textured design and solid colour decorative laminates are different.

Step 2. Manufacturing Process for solid colored and printed design decorative laminate.

Solid Coloured Decorative Laminate

In this process decorative layers saturates in more durable melamine resin as shown in pictures and two big rolling rings remove excess resin. This resin treatment makes resin more stiff and brittle so that it can sustain wear and tear of laminate.

Printed Design Decorative Laminate

In this process workers cut decorative layer paper into craft paper size and are stacked by placing an overlay on each other according to designs. These overlay papers are transparent to each other which further saturated with melamine resin.

Step-3: Drying

The Saturated papers (both Solid coloured and Printed design) are placed in a drying ovens which blows hot air and dries resin in few seconds.

Step-4: Stacking

Now each dried decorative layer is placed with craft paper. On top of each decorative layer a textured plate is laid, this will prevent the finished laminates from sticking together.

Step-5: Thermosetting

After stacking decorative layer with craft paper on each other, an intense heat and pressure is applied to bind them. The textured plates between each set meanwhile imprints their print on to the heat softened resin, texturing the laminate surface.

Schematic Diagram of Laminate Manufacturing Process

Advantages and Disadvantages of Laminate

Advantages of Using Laminates

- Laminates are easy to clean.

- They don”t require polishing or painting

- Laminates are easy to install

- They are relatively hygienic and easy to maintain

- Resistant to scratch and abrasion

- Resistant to moisture and shock

Disadvantages of Using Laminates

- Laminates are difficult to recycle

- If the top layer get worn then whole laminate sheet has to replaced

- If laminate sheets are used for flooring, then it’s create very slippery surface

- Laminates are brittle hence they are prone to clipping

- Laminates are difficult to bend

The installation process of laminate is very easy and it can apply on any surface and price of laminate is calculated by per sheet. The price of good laminate ranges from Rs.1100 onwards.

List of Good Quality Laminate Brands in India

Laminates are manufactured by many local and branded companies. Few branded manufacturers who produce Good quality laminate in India are:

- Century

- Greenlam

- Merino

- Sunmica

- Formica

- Greenply

- Golden laminates

Since Laminates are used for decorating the surface of your furniture, it is highly important that you not only choose the right colours and patters that gives the desired look but also choose the laminates that are resistant to abrasion and scratching to ensure its durability.