Marble is one of the most appreciated finishing materials to improve the aesthetics of your home/building. Selecting marble at a particular budget can be a daunting task for end user. Here we plan to make an attempt to make your life simpler by giving you tips for Marble Selection.

Understanding Marble as A building Material

Marbles are formed from calcite or dolomite crystals that are subjected to extreme heat and pressure in the interior of the Earth.

Though all marble are formed in the same way by nature, a marble may be unique and more highly sought after than others due to various factors like looks and availability. A high-end natural stone may have a distinctive look and precious rarity, as limited availability and high demand often create a gulf in pricing from one type to other marble type.

For example Calacatta Marble is unique in appearance and also extraordinary in that it is only available from one quarry in the world, located in Carrara, Italy.

Marble can be given a high polish with less effort than other polishable stones (such as granite and porphyry – reddish purple rock) but it is not just this thing that makes it so sought for.

Its typically large calcite crystals allow light to pierce without great absorption, bringing a depth to the stone that is unparalleled. The crystals at times sparkle like sugar.

The highest quality marbles are usually considered to be those with very little distinction from veining, spotting and other features, and the pure whites with evident translucence.

Marble choices customarily come down to aesthetics and what is factual in general holds good for marble: Beauty is in the eye of the beholder; pricing become secondary.

How Marble is Extracted from Earth?

Mining marble blocks from the wall of the quarry starts with a “bench Quarrying.” The bench quarrying creates, bench wall which is a large section of marble along a vertical wall that is cut with diamond cables, drills, and torches.

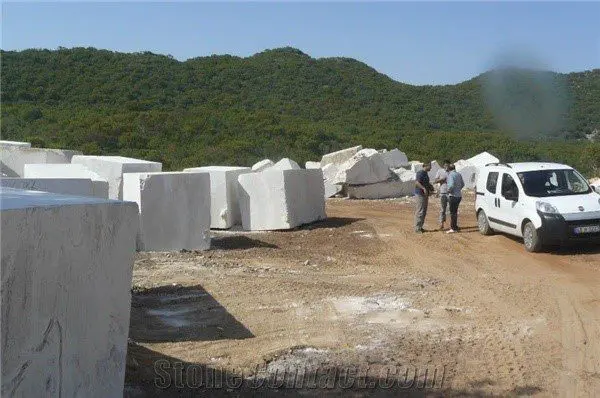

Once mining has begun, there may be several months of excavating before any marble is mined from the quarry. Overload, or dirt on top of the desirable ore, needs to be extracted before blocks of marble can be extracted.

Marble blocks are mined from examined marble quarry face (yielding the most favourable blocks).It is required to be supervised each cut made from the quarry; marble mined along the “vein” of the deposit will have a very altered look than marble that is “cross-cut” transversely the vein.

Newly extracted blocks are then firstly examined for dimensions, defects and more or less apparent veins which govern the quality and value for each block.

Smaller and irregular shaped blocks with good color are set aside to make strips that will be used to make tiles.

Where veining (pattern of veins or streaks), spotting and other features occur, the colour and intensity provide the character that can be completely changed in the end product by altering the alignment of sawing the blocks into slabs.

Technology Used for Cutting Marble and Polishing:

Two basic types of machines are involved in the processing marble blocks: saws & polishers

Saws:

Saws perform several tasks during fabrication. A block saw, or gang saw, cuts the massive stone blocks into slabs. A metal wire is embossed with industrial-grade or synthetic diamonds, and this wire rapidly cuts through stone as hard as granite, water is sprayed onto the blade to cool it through the cutting process.

Gang Saw Machine Cutting Marble

Polishers:

Polishers grind down the naturally rough surface of the stone to multiple finishes the consumer desires. Hard stones like marble and granite can be polished all the way to a mirror finish. The polisher consists of rotating pads which are textured with an abrasive material. The finer and smaller the abrasive grits are, the higher the polish.

Machine for Polishing Marble Slabs