Due to climatic adversities and abnormality in loading or a chemical attack, a significant damage could be caused to a member or to structure as whole. Appropriate repair, restoration and strengthening measures must be provided to avoid any premature failure.

The first step is to find the cause or source of the aroused defect and after collecting adequate information about defect and corresponding region, the repairing method and materials are selected.

Mostly, non-shrink repair materials which possess easy application properties are preferred and its compatibility with parent material is most vital criteria. The repair material must be durable, economically consistent and should not accelerate the existing damage.

Materials used for RCC Repair Works

1. Non-Shrink Grouts

Grouts are suitably used for small repair works such as crack filling cement concrete. It is used due to it’s readily availability and it is cost effective. In case of non-shrink grouts, their volume does not change upon setting.

Polymers are also used in mix to improvise its tensile strength and adhesive property. It develops an appreciable bond with existing concrete and if used with suitable admixture, it enhances strength and reduces curing time while enhancing workability.

2. Shortcrete

Shotcrete is pneumatically applied mortar or concrete mix, containing coarse aggregates size limited to 10 mm. Shotcrete is sprayed directly to the effected region or surface using compressed air.

Application of shotcrete through jet nozzle at high velocity produces a compact homogeneous mass on the surface of existing material. Shotcrete application is preferred when the required repair work is at large extent and application through other methods is impractical or uneconomical.

3. Epoxy Resins

For the defects such as large cracks or holes and to provide a surface coating, adhesive agents possessing high tensile strengths such as Epoxy resins are used.

The most advantageous merit for using Epoxy resins is that their composition can be changed as per requirements and suitable epoxy resin can be mixed right before the application. Depending upon viscosity, epoxy resins could be applied for both fine cracks (low viscosity) and large cracks (high viscosity).

For surface coating, Epoxy resins with high viscosity are used. Moreover, these adhesives can also be used to attach steel plates for strengthening the damaged structures.

4. Epoxy Motar

With addition of low viscosity resins with fine aggregates to amplify its usage in filling voids or gaps of large sizes. Epoxy mortar possesses better compressive strength but lower modulus of elasticity than cement concrete. To enhance modulus of elasticity, sand is added while formation of epoxy mortar.

5. Fiber Reinforced Plastics or Polymers

FRP could be used as replacement of steel plates, while strengthening of reinforced concrete or masonry structures. FRPs provide higher corrosion resistance and high strength to weight ratio. Adhesives such as epoxy mortar could be used to attach these plates to the affected region of structure.

6. Latex Emulsions

Various emulsions such as Polyvinyl Acetate (PVA) , Styrene Butadiene (SBR) latex, Acrylic latex are used as bonding agents. These are basically used to enhance bond between fresh concrete and existing concrete.

Moreover, these can be applied over moist surfaces also because these provide a waterproofing layer and can be used as anti-carbonation coating over concrete.

7. Rust converting Primers and Corrosion Inhibitors

Alkaline rust converting primer can be used on rusted steel frames. Its application forms a deoxygenating complex agent which makes the affected steel more corrosion resistant.

Most rust converters are safer for application and for environment as they are water based, free from mineral acids and produce no fumes and could even be used in enclosed spaces.

Corrosion inhibitors diffuses through densest concrete to reach corroding steel as these possess high affinity for embedded metal and high vapour pressure.

Corrosion inhibitors can easily reach the unexposed side of reinforcement and assures protection to reinforcement, even in presence of chlorides. Corrosion inhibitors are mostly used for coastal structures, structures subjected to damp conditions, etc.

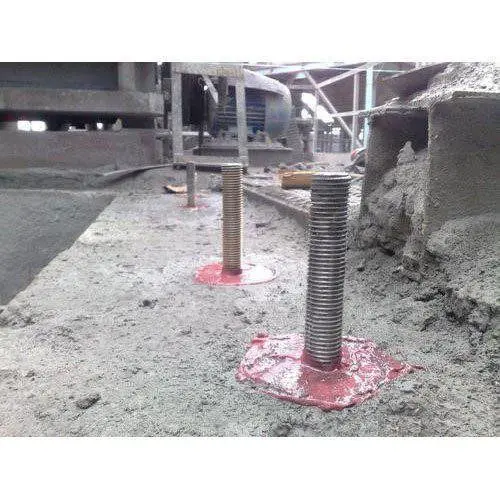

8. Anchors

Mechanical anchors are fasteners used to provide anchorage through wedging actions to concrete or masonry structures. These are used to provide extra strength to structure to resist tension as well as shear stresses. Mechanical anchors are inserted in concrete and then they expands, this causes anchor to grip and provides strength.

Chemical anchors are preferred for fastening concrete at places where more flexibility is required. The chemical injected into cavity fills in irregularities and makes the cavity airtight, this phenomenon provides extra strength.

– Tushar Meena