A door may be defines as an “openable barrier or a framework of wood/steel/Aluminum/glass or a combination of these items in a wall opening.

Parts of A Door

Mainly, There are two components in a Door

1. Door Frame

- A door frame is an assembly of horizontal and Vertical members forming an enclosure to which doors are fixed

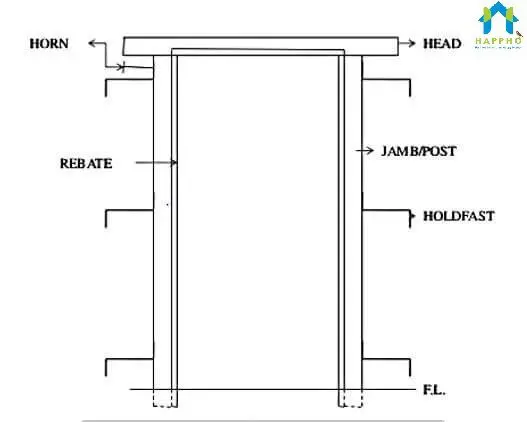

A Typical Door Frame

- The Vertical members are called Jambs or Posts

- The top Horizontal member is called a Head

- The Hrizontal Projections of the head are called Horns, which is important for the frame to act as a combined unit with the wall

- A rebate cut of 12 mm is provided all around the frame to receive door shutter

Door Frames are generally made of

- Timber

- Steel

- Aluminium

- Concrete

- Stone

Note: The Head of the Frame is structurally the strongest member of the entire door. So proper care has to be taken regarding the wood selected for the frame in terms of moisture content and specific gravity of wood.

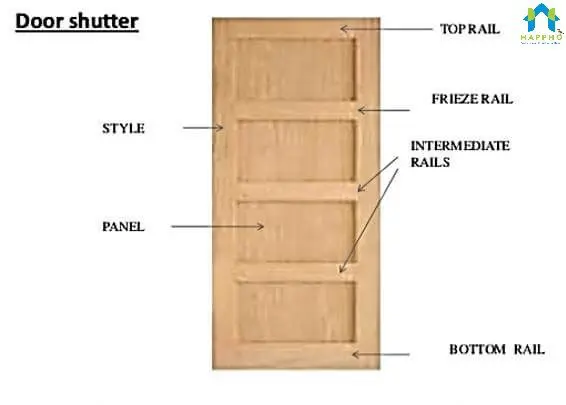

2. The Door Shutter

Door shutters are generally made of

- Timber

- Plywood

- Glass

- Block

Guidelines for Designing the layout of doors

- The Number of Doors should be kept as minimum

- The should be preferably located at a corner of a Room ( Residential) approximately 20 cm from that corner

- If a room has 2 doors, they should be preferably located facing each other to facilitate Cross-Ventilation.

- The door should not be kept in the centre of the wall.

Typical Dimension ratio's of Doors Used in India

- Width = 4 X Height (in India) can go upto 0.6 X Height

- Height = (Width +1.2) m

Standard Dimensions of Doors Used in Residential Buildings

Standard dimensions of the doors used in the various residential building are as followings:

- External Doors : 1.0 X 2.0 m to 1.1 X 2.0 m

- Internal Doors : 0.9 X2.0 m to 1.0 X 2.0 m

- Bath & WC : 0.7 X 2.0 m to 0.8 X 2.0 m

Why are Doors Mostly Made up of Wood

Wood is the oldest material used by humans for construction after stone. Despite its complex chemical nature, wood has excellent properties which lend themselves to human use.

It is readily and economically available;

- Easily machinable

- Amenable to fabrication into an infinite Exceptionally strong relative to its weight

- A good heat and electrical insulator

However, it also has some drawbacks of which the user must be aware. It is a “natural” material and is available in limited amount.

Following properties of wood makes it good for use in construction.

Specific Gravity of Wood used for Doors

Generally, specific gravity (SG) and the major strength properties of wood are directly related. SG for the major, usually used structural species ranges from roughly 0.30 to 0.90. Higher allowable design values are assigned to those pieces having narrower growth rings (more rings per inch) or more dense latewood per growth ring and, hence, higher SG

Moisture Content and Shrinkage of Doors

Undoubtedly, wood’s reaction to moisture provides more problems than any other factor in its use. Wood is hygroscopic ; that is, it picks up or gives off moisture to equalize with the relative humidity and temperature in the atmosphere.

As it does so, it changes in strength; bending strength can increase by about 50% in going from green to a moisture content (MC) found in wood members in a residential structure, for example. Wood also shrinks as it dries, or swells as it picks up moisture, with concomitant warpage potential.

Critical in this process is the fiber saturation point (fsp) , the point (about 25% moisture content, on oven-dry basis) below which the hollow center of the cell has lost its fluid contents, the cell walls begin to dry and shrink, and wood strength begins to increase. The swelling and shrinkage processes are reversible and approximately linear between fiber saturation point and 0% MC.

Wood decay or fungal stain do not occur when the MC is below 20%. There is no practical way to prevent moisture change in wood; most wood finishes and coatings only slow the process down. Thus, vapor barriers, adequate ventilation, exclusion of water from wood, or preservative treatment are absolutely essential in wood construction.