Pre-engineered buildings are basically steel structures, the structural members like columns, roof truss, purlins etc. being pre-fabricated in a factory in accordance with the design specifications and they are erected in the site, joined together using bolts.

The prefabricated structural members are usually “I” sections. The foundations of these buildings are the conventional concrete foundations to support the lighter super structure and to carry heavy loads. The floor of such buildings is also built of conventional concrete in certain cases.

This type of pre-engineered building is preferred for

- Low rise industrial buildings

- Ware houses

- Power plants

- Laboratories

- Airport hangers

- Parking lots

- Factories etc.,

Where it is necessary to have a large floor space area that is intermediate columns are to be avoided. In these cases conventional concrete proves useless because over such long spans, the load due to its own self weight increases, thus making the structure critical.

A One Storey Residential Pre-Engineered Building

Steps involved in Construction of PEB Structure

Step-1: Design of PEB Structure

The steel frames to be used in a particular structure is extensively designed and fabricated in a company. This design involves the use of meticulous design software giving no room for any error or change in the structural frames. Thus design forms a key aspect in the construction of a PEB

Step-2: Construction of Foundation

This step involves the conventional construction practise of site clearance and building of concrete foundations. Usually shallow isolated foundations are preferred for a PEB since the self-weight of the super structure is very less.

In severe exposure areas like coastal zones pile foundations are laid but the depth of the pile is less when compared to the conventional concrete structures. They often prefer to lay a flat slab base of PCC below the pedestal (isolated footing of shallow depths) to prevent its direct contact with the soil. The columns of the super structure are bolted to the pedestal.

Step-3. Erection of Steel Frames

The grade of steel used varies based on the structural requirement, for instance if it is a one storey building then the thickness of the steel provided can be less (.9mm to 1.2 mm) but for a warehouse (large structure) thickness to be provided increases (4mm to 50mm).

The steel columns and beams are bolted together. Steel is also used in roofing of a one storey building and for both floors and roofs in two or more storey buildings.

Step-4. Construction of Walls on all Sides

The final step in construction of a PEB is building the walls. Usually for a PEB the walls are built with different range of materials like granite, fibre cement insulated panels, insulated steel or aluminium panels, conventional brick work, stone cladding etc., the choice depends upon the user. But generally insulated steel panels are preferred because of their structural stability.

Advantages of Pre-Engineered Building

- Reduced Construction time: When the foundation is being built in site, the structural members are simultaneously fabricated in industries. Since the erection time is also less it results in the early completion of the structure

- Less Manpower at Site: Most of the work in a PEB construction is done in the industries thus the requirement of manpower at the site is very less comparatively

- Reduction in Cost: Since both materials and manpower is minimized the overall cost of construction is reduced

- Flexibility in Design: The steel structural members are designed in software and is fabricated with machines, thus desired shape can be achieved without any compromise. Hence the PEB can be architecturally versatile

- Scope for Future Expansion: Since bolted connections are only used, the length wise expansion in a PEB becomes more evident

- Low Maintenance: Modern metal finishes and coatings will help the steel panels to resist corrosion, chemical attack etc., and also the steel surfaces can be easily repaired if damaged.

- Seismic Resistance: The super structure made of steel is light in weight and flexible enough to offer greater resistance to seismic waves when compared to conventional concrete structures.

Disadvantages of a PEB structure

- Susceptible to Corrosion: If not properly maintained the steel frames are susceptible to corrosion, thus special coatings becomes necessary to resist the corrosion of steel

- Low Thermal Resistivity: Steel being a metal is good at conducting heat, thus it reduces the thermal comfort in the building.

- Low Fire Resistance: During fire, this type of building becomes more susceptible to damage due its conductivity.

Abbreviations used:

PEB- Pre-engineered building

PCC- Portland Cement Concrete

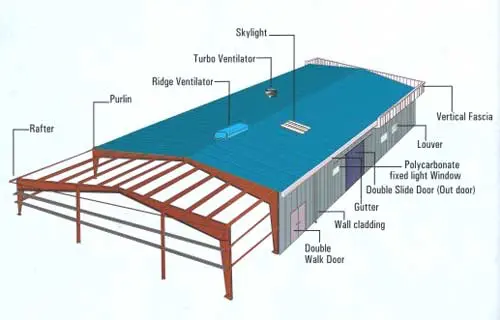

A Typical PEB Structure