Rainwater harvesting techniques have been already been devised and used since ancient time. These were implemented at the community level in areas where rainfall is the only major source of freshwater, mostly in Rajasthan, Madhya Pradesh. In Southern India rainwater harvesting systems are integrated into their architecture in the form of small ponds/tanks for each house, and temple tanks.

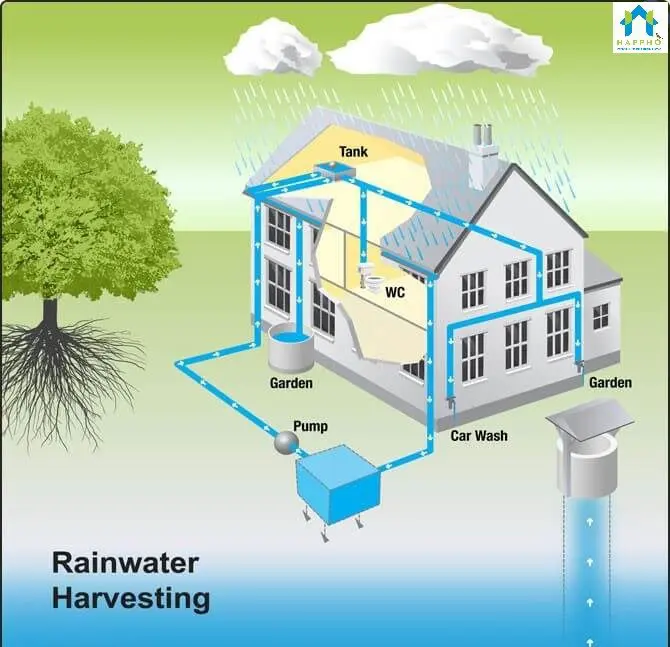

The basic rainwater harvesting system is more of a plumbing job than a technical job, as all the outlets form the buildings’ terrace are connected through pipes to an underground tank which stores water or a dugwell, which serves the purpose of recharging wells and borewells.

Advantages of Rain Water Harvesting System

- Reduces the dependency on ground water, hence potable water is available even during droughts, floods, etc. and is particularly useful where the groundwater is contaminated with chemicals like pesticides, fluoride, etc.

- These are easy to construct, easy to maintain, and easy to operate, and the investment is also less.

- It reduces soil erosion, and conserves groundwater.

Roof Top rainwater harvesting, the roof becomes the catchment area, and the rainwater is collected from the roof of the house/building.

Components of rain Water Harvesting System

The Various components of a rainwater harvesting system are

1. Catchment or Catchment Area

This is the area which directly receives the rainwater. For buildings, roofs made of RCC and corrugated sheets can be used as catchments. RCC roofs need a slope to drain the rainwater from the roof into conduits/pipes which transport the water to collecting pits/tanks, etc. The outlets from the roof of the building should be covered with a mesh which will stop stones and other debris from entering the RWH system

2. Gutters

As most corrugated roofs are sloped, and gutters attached at the edges can collect the water draining from the sloped roof. The gutters can be of circular or rectangular cross section and can be made using iron or aluminum sheets, PVC pipes, or Bamboo, whichever is locally available and economical. PVC pipes (cut in half, to form a semi-circular cross section) are the most durable.

3. Pipes / Conduits

These transport the rainwater collected form the catchment to the harvesting system, using gravity. PVC pipes are commonly used as they are economical and durable. The pipes provided are of 90-120mm diameter, however for major RWH systems the National Building Code 2005 (SP-7) has specified the ideal diameter of the pipe to be used in the following table –

| Diameter Of pipe (mm) | Average rate of rainfall in mm/h | |||||

| 50 mm/hr | 75 mm/hr | 100 mm/hr | 125 mm/hr | 150 mm/hr | 200 mm/hr | |

| 50 | 13.4 | 8.9 | 6.6 | 5.3 | 4.4 | 3.3 |

| 65 | 24.1 | 16.0 | 12.0 | 9.6 | 8.0 | 6.0 |

| 75 | 40.8 | 27.0 | 20.4 | 16.3 | 13.6 | 10.2 |

| 100 | 85.4 | 57.0 | 42.7 | 34.2 | 28.5 | 21.3 |

| 125 | – | – | 80.5 | 64.3 | 53.5 | 40.0 |

| 150 | – | – | – | – | 83.6 | 62.7 |

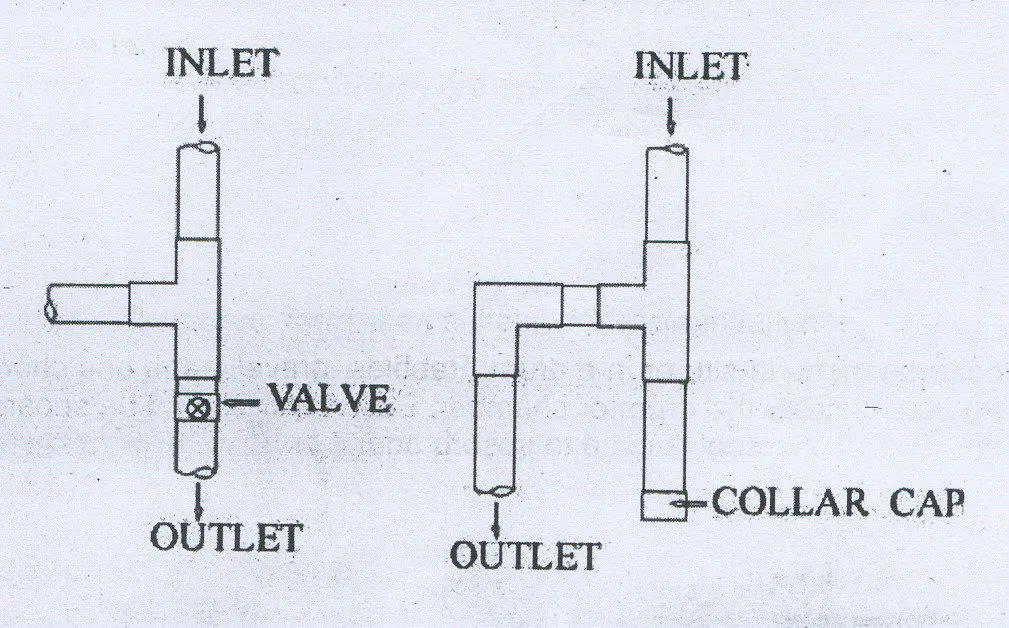

4. First Flush

First flush is a mechanism which discards the water received in first shower. The first shower of rains contains impurities and contaminants, such as dust, very low quantities of pollutants, organic matter, etc. The first rain separator should be attached at outlet of each drainpipe.

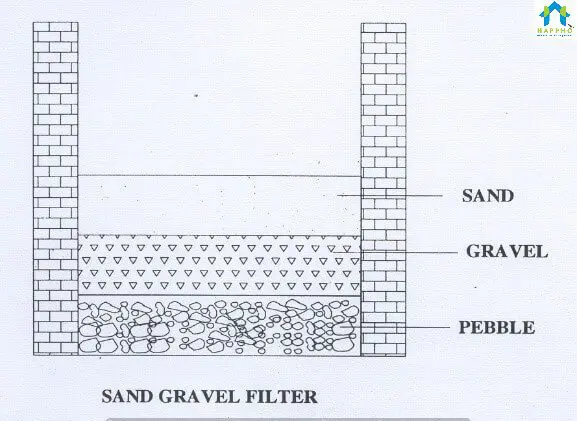

5. Filter

The water from the conduits/pipes is made to pass through the filter to remove the suspended particles and micro-organisms from water before it enters the storage tank or recharge well. A filter is made up of filtering media such as very fine fibre mesh (muslin cloth), coarse sand and gravel Charcoal can be added for a better quality of purification. There are different types of filters –

A. Charcoal Water Filter

A simple charcoal filter can be made in a plastic drum or an earthen pot. The filter is made up of layers of gravel, sand and charcoal, all of which are easily and cheaply available. The charcoal needs to be periodically replaced, usually once a year, before the rainy season. It needs to be replaced more often, depending on the quantity and quality of water collected form the catchment.

B. Sand Filters

The major filtering media is sand. Sand filters are easy and inexpensive to construct and maintain. These filters are used for treatment of water to effectively remove turbidity (suspended particles like silt and clay), colour and microorganisms.

The formation of schumutzdecke (a layer of microbes which digest organic matter) further helps in filtering the water, but this needs to be periodically cleaned. In a simple sand filter that can be constructed domestically, the top layer comprises coarse sand followed by a 5-10 mm layer of gravel followed by another 5-25 cm layer of gravel and boulders.

Each layer should be separated by wire mesh. In larger sand filters, the enclosing chamber is made of RCC or masonry. There is provision for overflow and a splash plate. The filtering media consists of 20cm sand, 20cm gravel (8-10mm), 30cm sand, 40cm of gravel (8-10mm) – from top to bottom in this order.

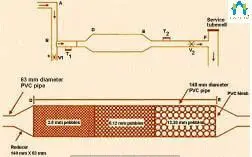

C. PVC pipe Filter

This is an indigenously developed filter which consists of a polyvinyl chloride (PVC) pipe 140 mm in diameter and 1.2m long. There are three chambers.

The first purification chamber has pebbles varying between 2-6 mm, the second chamber has slightly larger pebbles, between 6 and 12 mm and the third chamber has the largest – 12-20 mm pebbles.

There is a mesh at the outflow side through which clean water flows out after passing through the three chambers. This is a low cost alternative to the sand filter suitable for rural areas where the scale of RWH is small.

D. Sponge Filter

This filter is made from a 90 litre High Density Poly Ethylene (HDPE) drum. The lid is perforated. This is the first sieve which keeps out debris. The rainwater then passes through three layers of sponge and a 150mm thick layer of coarse sand.

Presence of sponge makes the cleaning process very easy. The first layer of sponge is periodically removed and cleaned, if needed it is replaced. It is the simplest and cheapest form of filter.

6. Storage facility

The water demand in urban areas is usually in the range 135-225 liters per person per day (IS 1172). In rural areas, it can be as low as 80 liters per person per day. The capacity of the storage tank for the rainwater should be designed accordingly. The various characteristics of the storage tank are –

- Shape: Cylindrical, cuboidal, etc.

- Material of construction – RCC, ferro cement, masonry, plastic (polyethylene) or metal sheet (galvanised iron)

- Position of tank: Depending on the availability of space and cost considerations storage tanks can be constructed above ground, partly underground or fully underground. Some periodic maintenance like cleaning and disinfection is required to ensure the quality of water stored in the container is not affected.

7. Recharge Structures

When the rainwater collected contains high amount of impurities, such that the cost of purification is high, and the prcess is too complex and difficult. The rainwater then may be charged into the groundwater table through recharge structures like dugwells, borewells, recharge trenches and recharge pits.

Various recharge structures are possible – recharge pits/trenches promote the percolation of water through soil strata at shallower depth, whereas recharge wells (sometimes fitted with pressure filters) conduct water to greater depths.

At many locations, existing structures like wells, pits and tanks can be modified as recharge structures, eliminating the need to construct any structures afresh. Here are a few commonly used recharging methods:

A. Settlement Tank

Settlement tanks are used to stagnate the rainwater to allow removal of silt and other floating impurities from rainwater. A settlement tank is like an ordinary storage tank having provisions for inflow (bringing water from the catchment), outflow (carrying water to the recharge well) and overflow.

A settlement tank can have an unpaved bottom surface to allow standing water to percolate into the soil. The settlement chamber acts like a buffer in the system. A storage tank can be used as a settlement tank. The typical volume of a settlement tank is 1.5 to 5 cubic meters.

B. Recharge Pits

A recharge pit is 1.5m to 3m wide and 2m to 3m deep. The excavated pit is lined with a brick/stone wall with openings (weep-holes) at regular intervals. The top area of the pit can be covered with a perforated cover. This allows the rainwater to infiltrate the soil and recharge the groundwater table.

C. Soakaways / Percolation Pit

Percolation pits, one of the easiest and most effective means of harvesting rainwater, are generally not more than 60 x 60 x 60 cm pits, (designed on the basis of expected runoff as described for settlement tanks), filled with pebbles or brick jelly and river sand, covered with perforated concrete slabs or slotted pipes at appropriate depths at which pervious soil is available.

D. Recharge Trenches

A recharge trench is a continuous trench excavated in the ground and refilled with porous media like pebbles, boulders or broken bricks. A recharge trench can be 0.5 m to 1 m wide and 1 m to 1.5 m deep. The length of the recharge trench is decided as per the amount of runoff calculated.

The recharge trench should be periodically cleaned of accumulated debris to maintain the intake capacity. In terms of recharge rates, recharge trenches are relatively less effective since the soil strata at depth of about 1.5 metres is generally less permeable. Recharge trenches usually require less maintenance

E. Recharge Troughs

To collect the runoff from paved or unpaved areas draining out of a compound, recharge troughs are commonly placed at the entrance of the plot. These structures are similar to recharge trenches except for the fact that instead filling the excavated portion with filter materials, a number o boreholes are drilled at suitable spacing in the trench. These do not require any filter material. The amount of runoff that can be handled by recharge troughs is limited because of the limitation in space and size.

F. Recharge Well with Pressure Filter

This method is suitable for areas with low ground water table and presence of impervious strata, which hinders the infiltration of water into the ground water table. In this method water is first collected in an underground tank, which contains a filter bed of layers of sand gravel and then the water is pumped into the ground through borehole containing a sotted or perforated GI pipe into the ground water table. not pumped into the aquifer but allowed to percolate through a filter bed, which comprises sand and gravel. The annular space between the borehole and the pipe is filled with gravel and developed with a compressor till it gives clear water.

Treatment of Rainwater

The chemical treatment of stored rainwater is to ensure that it is not re-contaminated. The most common types of treatment are –

i) Chlorination: Chlorination can be carried out by using bleaching water and/or chlorine tablets, both of which are readily available commercially. A single 0.5g ‘halazone/chlorine’ tablet is sufficient to disinfect about 20 litres of water. Bleaching powder has multiple applications, it can also be used to disinfect other parts of the RWH system, and it is generally available in powdered form.

ii) Boiling: Boiling is a very effective method of purification and very simple to carry out. Boiling water for 10 to 20 minutes is enough to remove all biological contaminants and it also removes hardness of water. But this is suitable for small scale RWH systems only as a large amount of water needs a larger amount of fuel for boiling.

iii) Direct sunlight: This can also be used to kill many of the harmful bacteria in water by exposing it in clear glass or plastic bottles for several hours to the UV radiation which is a part of sunlight. The water must be clear form turbidity and clear weather are the prerequisites for this type of treatment. Most of the microorganisms are killed by the effect of UV rays and the heat generated due to exposure to sunlight.

Do's and Don'ts of RWH system

The following precautions must be taken to ensure that the RWH system operates at maximum efficiency:

- The catchment area, i.e., the roof/trace used for harvesting should be clean, free from dust, organic matter such as vegetation etc. and should not have any obstructions to the flow of the rainwater They should be properly cleaned before tee the monsoons. This increases the service life of the filter media used in the different components of the RWH.

- Provide gratings at mouth of each drainpipe on terraces to trap leaves debris and floating materials, as thses may damage the filter media

- Provision of first rain separator should be made to flush off the first rains, due to the potential risk of acid rains and presence of contaminants form the roof/terrace.

- Polluted water, such as the water containing soap and other cleaning products, shpuld not be used to recharge ground water. Ground water should only be recharged by rainwater.

- Before recharging, it should be made sure that all the components of the RWH are in working order and there are no obstructions and waste material in the storage and settlement tanks. Filter media should be cleaned before every monsoon season.

- During rainy season, the whole system (roof catchment, pipes, screens, first flush, filters, tanks) should be checked before and after each rain and preferably cleaned after every dry period exceeding a month. At the end of the dry season and just before the first shower of rain is anticipated, the storage tank should be scrubbed and flushed off all sediments and debris.

– G. Arvind Kumar