Steel reinforcement play very critical role in influencing the structural behaviour of concrete.

- They are strong in tension at the same time ductile enough to bent or shaped.

- Thermal expansion of steel and cement are approximately same.

And it bonds well with the concrete.plain concrete without steel or any other reinforcement is strong in compression but weak in tension.steel is one of the best form of reinforcement to take care of tensile strength.

Introduction to Iron and Steel

- Wrought iron- iron that contain glassy inclusions.

- Cast iron- iron which holds 4% carbon.

- Steel- iron with a bit of carbon it as much as 1%.

- Pig iron- pig iron consist of 5% of carbon due to which it is very brittle and makes it very brittle and not very useful directly as material

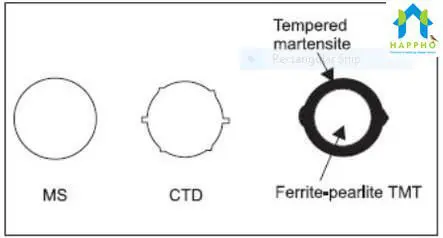

Reinforcement Steel Type

- Plain mild steel of grade Fe-250 (not used much)

- Cold Twisted Deformed bar (CTD)-it involves stretching twisting of mild steel,beyond the yield plateau and subsequently releasing the load.(yield strength in range of 405 MPa)

- high strength deformed bar or TMT (Thermo Mechanical Trated) Bar. they are available in various grades like Fe-415,(415 MPa yeild strength ) Fe-500, Fe-500-D, Fe-550, Fe-600 etc.

- Steel are available in different diameters 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 32mm.

Field test at Site to Check Steel

- Steel bundle should have tag giving details of batch/lot details which confirms that supplied material is as per the requirement of relevant indian standard code.

- Weight per meter (w/m)-for any steel reinforcement bar weight per running meter is equal to d2/162 kg, where d is diameter of bar in mm.

Tolerance on Nominal Mass of Steel Bar

[table id=7 /]

- Bend test : specimen should be doubled over the mandrel by continuous pressure until sides are parallel.if there is no rupture is visible then bar is perfect.

- The bar should be bend at included angle 135 using mandrel and then keep it in boiling water for half an hour and then allow it to cool after that bar should rebend to included angle 157 ½ now if there is no rupture or crack is visible then bar is perfect for construction.

Work Procedure for Fixing Reinforcement Steel

1. Reinforcement brought to site should clean, free from paint,mud,oil,grease or any deleterious material which harmful to concrete or steel.

2. Bar bending schedule to be made as per IS code recommendation and should be duly checked by project manager and after his approval bar bending and cutting should done.

3. Formwork to receive should be clean and free from debris.

4. Ensure that size of lot,diameter of bar, spacing between bar, correct bends, proper laps, enough chairs kept in proper position and cover blocks in order.

5. Number of laps and chairs to be recorded on BBS (Bar Bending Schedule) as per actual placed at site.

6. Reinforcement should be placed and tied in such a way that concrete placement be possible without segregation of concrete.

7. When bar laps on another bar then lap length should take about 50 times of diameter of bar or use mechanical mechanical splice.

8. Top ring should not be half inside the concrete and half outside the concrete as shown in picture it shall be 40 mm below the top concrete same to be ensured for column concrete.

9. No binding wire knot shall come outside cover zone.general consumption of binding wire should be 9 to 12 kg/MT residential bungalow/podium.

10. All hooks or stirrups of rcc to be bend to 45 degree.

11. Provide stirrups about 600mm above shuttering top so that needle vibrator can be inserted without any kind of obstruction.

12. Provide master ring at every 1m in the column.