Concrete is a composite material that essentially consists of a binding medium embedded with fine aggregate, coarse aggregate with or without chemical and mineral mixture.

Primary Reasons To Use Concrete in Construction

- Concrete possesses excellent resistance to water.

- It easily forms structural concrete element in the variety of shapes and sizes.

- It is cheapest and readily available material on the job.

Concrete Ingredients

1. Cement

The following are the types of Portland Cement available in the market.

Ordinary portland cement (IS 12269)

- 43 grade (IS 8112)

- 53 grade (IS 12269)

- Portland pozzolana cement (IS 1489)

- Portland slag cement (IS 455)

All these cements are different chemically, physically and mineralogically in their formulation. So these cements can’t be substituted for each other in given concrete mix.

The main purpose of cement is to increase strength in concrete but cement content in concrete has to be kept minimum to get an economical and volume stability (cement increase drying shrinkage and plasticity of concrete).

2. Water

Water plays the primary role in Cement hydration and concrete workability and its content should keep as according to concrete mix design so that it will not decrease strength in concrete and porosity in concrete and use precaution to use only drinking water.

- Portable waters are generally considered satisfactory for mixing and curing of concrete.

- Impure water used to make concrete can cause problems when setting or in causing premature failure of the structure.

3. Aggregate

Aggregates are a chemically inactive material which is bonded together by cement. Most of the aggregates used are naturally occurring aggregate such as crushed sand, AGGREGATE :coarse gravel.

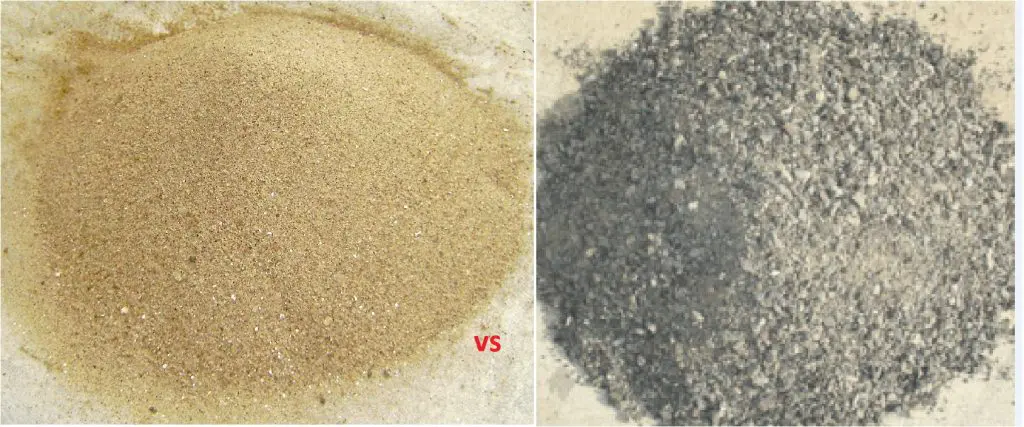

Aggregates are classified into fine aggregate and coarse aggregate according to is particle size and bulk density.

3(a). Fine Aggregate

The following should be the ideal properties of fine aggregate used in concrete

- Particle size smaller than 4.75mm.

- Natural sand is generally used as fine aggregate.

- Sand generally obtained from pits,river, lake, sea shore.

- When obtained from pits it should be wash thoroughly so that it should be free from silica.

- Sea-shore sand may consist chlorides which may cause efflorescences and may cause corrosion of reinforcement, hence it should wash thoroughly before use.

- Angular grained soil makes good concrete because of its good interlocking property while rounded grained soil does not afford such interlocking.

3(B). Coarse Aggregate

The following should be the ideal properties of coarse aggregate used in concrete

- Particle size larger than 4.75mm.

- It provides volume stability and abrasion resistance and reduce volume changes.

- Blast furnace slag, coal ashes may also be used as aggregates to obtain lightweight and insulating concrete of low strength.

- When very high strength concrete is required a very fine grained granite is perhaps the best aggregate.

- Coarsed grained rocks make harsh concrete and need high proportion of sand and high water cement ratio to get reasonable degree of workability.

4. Admixtures

Admixtures are material other than cement,aggregate and water that are added to concrete either before or during mixing to alter its properties and performance in fresh (workability, setting time etc.) and hardened state.(strength durability etc.)

These aggregates broadly classified into two types

- Chemical admixtures(water reducer,superplasticizer,retarder,accelerator etc.)

- Mineral admixtures (fly ash, metakaolin, silica fumes etc.)

Admixtures typically used for following purpose.

- As a water reducers.

- As a retarders

- As a accelerators

- As a air entertainers

- To increase flowability

- To increase workability

- To increase strength of concrete.etc.

What is Fresh Concrete?

Concrete which can be moldable and ready to place is called fresh concrete.

Main properties of concrete are

- Consistency- It is an ease with which concrete flow.

- Segregation- Separation of concrete ingredients from each other.

- Bleeding- In bleeding water comes out on the surface of concrete.

- Workability- It is an ease with which concrete can handle on site.

Types of Concrete

Concretes are classified into different ways

1. According to binding material used in concrete

- cement concrete

- lime concrete- mostly not used

2. According to design of concrete

- Plain cement concrete

- Reinforced cement concrete

- Prestressed cement concrete

3. According to purpose of concrete.

- Vacuum concrete

- Air entertained concrete

- Lightweight concrete

What is Water-Cement Ratio and Its Importance

- It is the ratio of volume of water mixed in concrete to volume of cement used.

- The strength and workability of concrete used is depend on quantity of water and cement used.

- More than optimum water increases the workability but decrease the strength. An increase in 10% above the optimum may decrease the strength approximately by 15% while an increase in 50% may decrease the strength to one -half.

- The excessive amount of water will not only decreased strength of concrete but also decrease durability, density and increase shrinkage.

- Water cement ratio needs to be 0.25 to complete the hydration reaction.

- Typical values of w/c are between 0.35 to 0.40 because they give good amount of workability without sacrificing lot of strength.

Mixing of concrete is done according to condition of site and importance of work as :

If construction site is small and requirement of concrete is less than generally concrete mixing is done on site by volume batching according to grade of concrete as below.and transportation is done using the concrete trolley.

Where as if the construction site is big and concrete requirement is high then concrete mixing is done at RMC (Ready Mix Concrete)plant by proper weight batching according to grade of concrete and transported on site using transit mixer mounted on truck.

Grades of concrete are M5, M7.5, M10, M15, M20, M25, M30…….M60. The garde of the concrete is decided/used according to importance of work.