Mushrooms aren’t just for eating anymore

– Quoted by Dwell

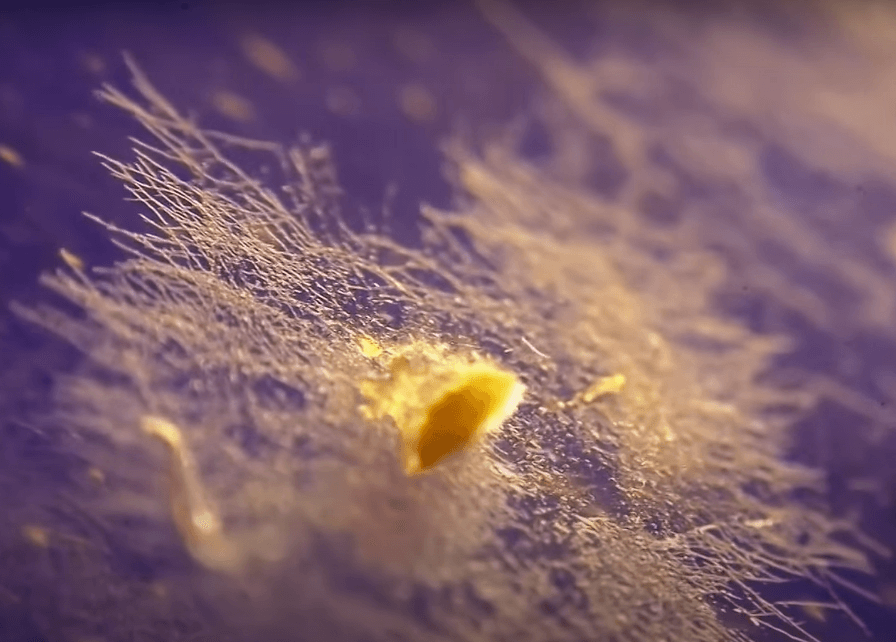

Fungus has been explored for decades, not only for its medicinal or edible usage but also for its engineering, strength, bonding, and as a useful sustainable material. The way it works as a material is uncomplicated: a substrate or an object is kept out as a food source and a fungus species (or subject) is placed on it to consume the object.

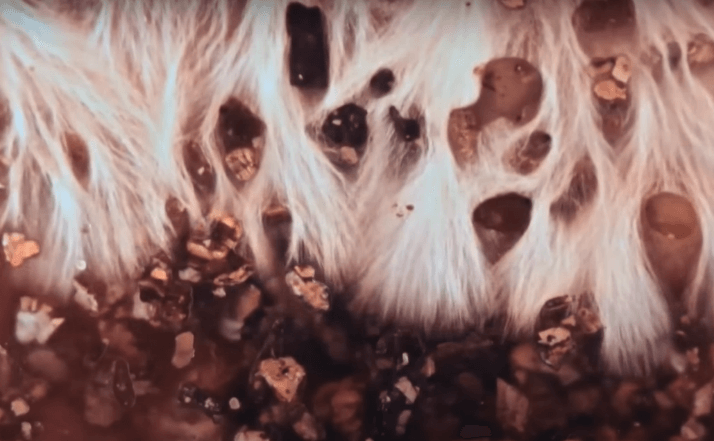

There is creation of fibres that is observed. Gradually, these fibres grow, strengthen and elongate. They start weaving into each other forming a bond and later a surface. These surfaces start layering one on top of the other (depending on the thickness and the hardness of the food source) and form a dense coating.

There are multiple fungi species that are researched upon and utilised, out of which mycelium stands out for its flexible yet dense fibres.

Different mycelium densities can be grown together seamlessly, making it a natural fire-resistant material, which can replace plastics, wood, concrete and polymers easily. This material can be moulded for forms that correspond to both exteriors and interiors, in terms of façades, furniture pieces and even walls.

Mushroom chair constructed from mycelium by MycoWorks is a waste-free, pollution-free furniture piece

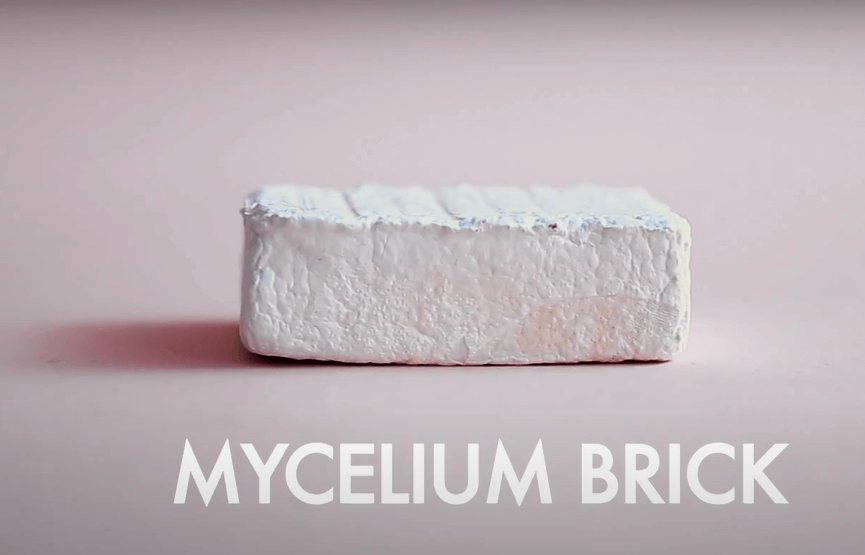

Mycelium bricks form one of the most recent yet widely used sustainable material. They are made from Mycelium which grow on rotten crops. It is hair-like and later turns into mushroom.

What makes Mycelium Sustainable?

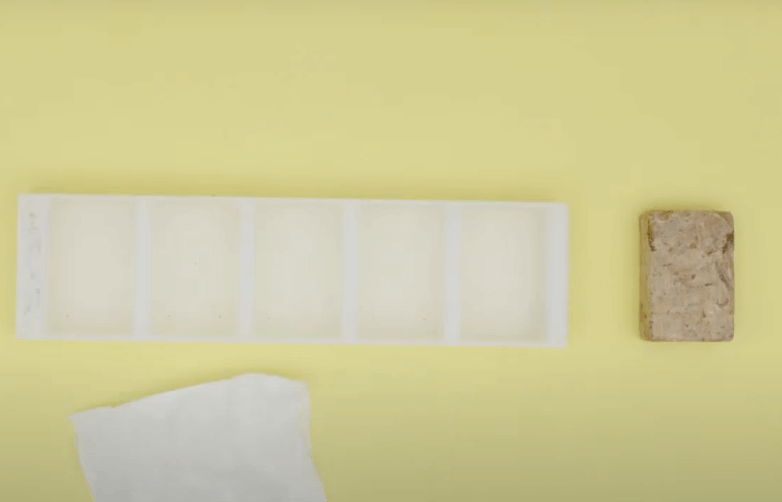

Standard inter-locking mycelium brick at moderate temperature

- There’s lesser reliance on fossil fuels, which is required in production of many other materials such as bricks, reinforcement bars etc.

- Less to no embodied energy is required for the fabrication of mycelium bricks.

- There is massive reduction in building waste since there is no requirement of additional bonding material and mycelium bricks grow, expand and contract over time.

- It is 100% bio-degradable

- As mentioned, it is water proof to a great level, provided correct and adequate proportions of sub-materials are used.

- Over time, they weave into each other in a way that there is porosity formed which also results in good ventilation and passage of air.

- Mycelium fibre ages, grows and interweaves well in high temperatures.

- In terms of structural integrity, it is as good as concrete, provided accurate proportions of the substrate material are used.

What makes mycelium a sustainable material?

There are many different ways to construct a mycelium block or a brick. One of the most common and easiest ways, suggested by MycoWorks is:

- Collect a mushroom sample. Leave it in open till it dries out and the tissues are visible.

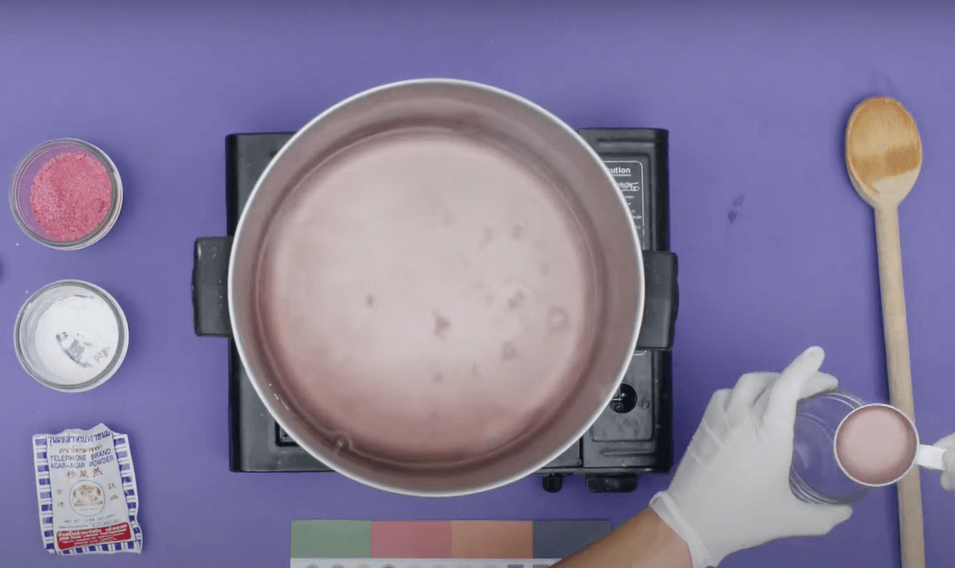

- Prepare the agar, a gelatinous substance obtained from seaweed. Put it in water and boil. Pour it in a container once ready.

- Place the mushroom tissue in the container filled with agar. One will observe how mushroom tissue settles on the surface and starts expanding in terms of hair-like fibres at slow pace. Wait for the mushroom tissue to form a semi-solid, semi-liquid mass.

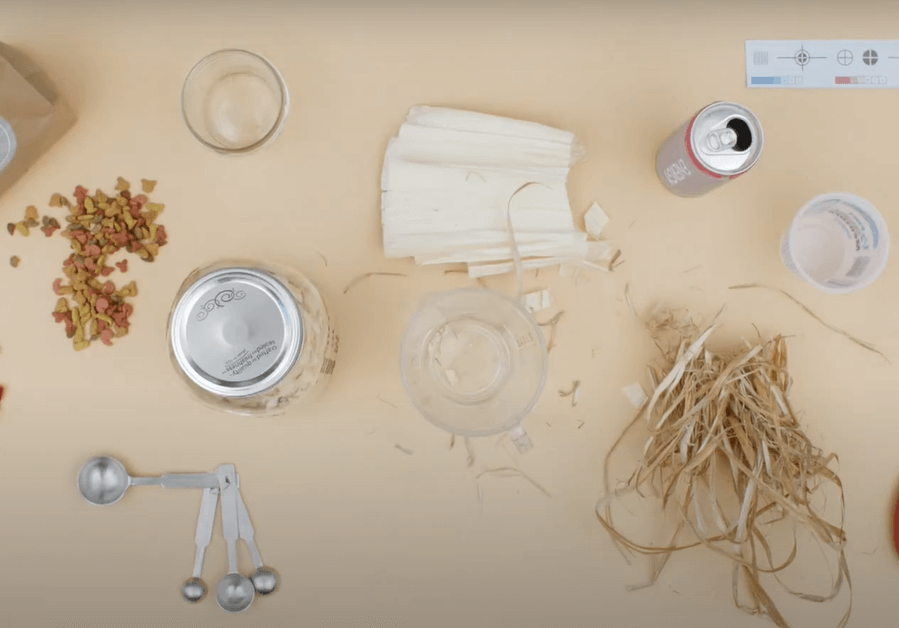

- Prepare the substrate (object or food source) for the mushroom tissue expansion. It can be a mixture of agricultural waste, sugars, pet food or even energy drink. Fill it up and confine it in a container.

- Once the mushroom mass is ready, place it in the container containing substrate mixture. Allow the mass to settle, increase in volume and occupy the substrate. Shut the container and shake it for the mass to reach out everywhere. This might take 3-7 days, depending on the amount and type of substrate.

- Remove the mushroom mass from the container once ready, break it up into smaller pieces and put it in a tray or mould in order to give it a particular form. Let it settle and strengthen under ideal conditions.

- Once the brick block or form is ready, remove it from the mould and let it stay in ideal conditions for approximately 7 days. Within these 7 days, the block will strengthen and dry out all the moisture content.

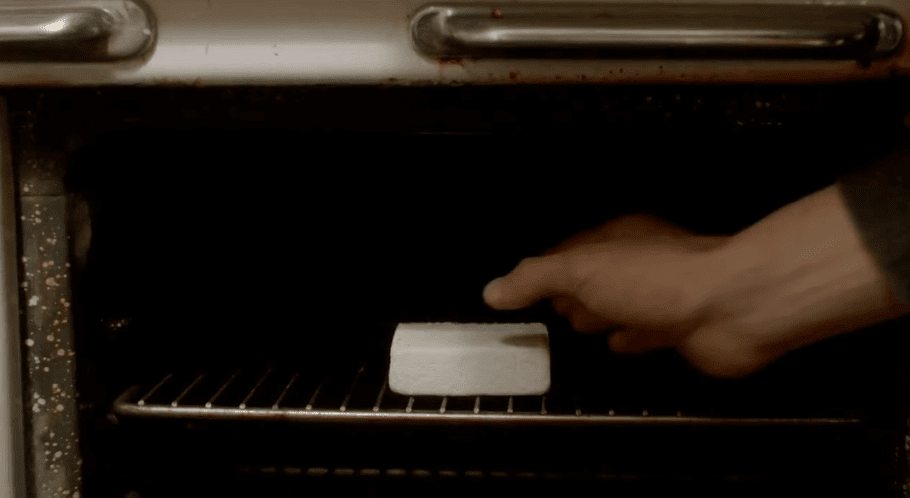

- Once the brick dries out, it forms a white powdery coating on top. Now place the block in an oven to kill all the unwanted organism, which might absorb moisture. Once baked, mycelium block is ready.

Advantages of Mycelium as construction material

- It is 100% biodegradable, hence temporary set-ups, installations can be easily erected and demolished based on usage.

- Mycelium tissue can trap more heat than fiberglass insulation, it is also fireproof and non-toxic.

- Wen dried, it becomes lighter due to porosity formation, but it is still stronger pound for pound than concrete.

- The production of mycelium is not time-consuming. It is fast, low-cost and easily produced material.

- There is almost no need for a bonding material since, when two mycelium bricks are placed together, they rapidly spread amongst them and become a bonding material.

- If maintained in favourable and stable conditions, mycelium bricks can have a lifespan of approximately 20 years.

Disadvantages of Mycelium as construction material

- The capacity of resisting water decreases over time and thus the mycelium bricks become vulnerable to mould and humidity over time.

- Mycelium bricks cannot be used for long term structures due to its decreasing resistance towards water, humidity and mould growth

- Usually no coating is required under normal climatic conditions, mycelium bricks expand, contract and relax according to the weather and when they remain untouched from ground. If they touch the ground, there is moisture absorption that takes place, lowering the efficiency of the mycelium bricks.

Some Structures Constructed using Mycelium bricks

- The HY-FI Mushroom tower by The Living for MoMA

These 12 metre high towers, which seem to interweave into each other as they go upwards, are completely constructed from mycelium bricks and corn stalks (substrate). The brick production required zero energy and there was no waste or even by-products produced. It was a temporary structure, which was demolished three months post its construction, the bricks used for construction were then used as a form of compost.

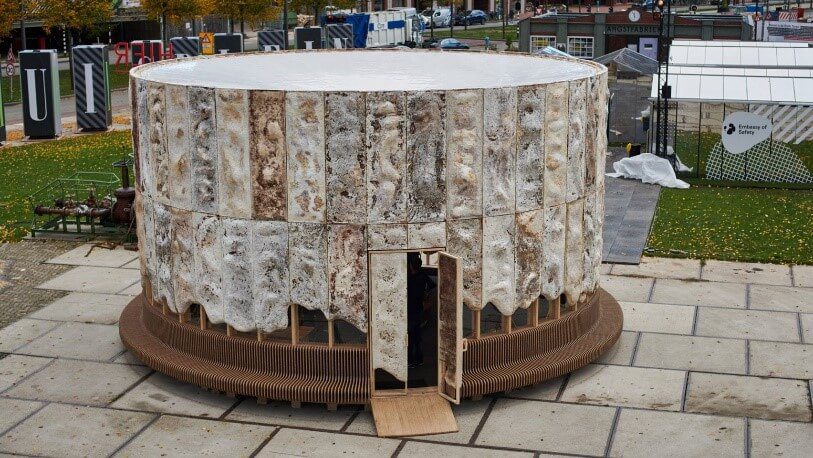

- Mycelium Pavilion by Pascal Leboucq (Company New Heroes),

This growing pavilion is composed of a timber frame and seating, the panels are made from active growing mycelium. It is a temporary public structure. The substrate used here is the agricultural waste obtained from the locals from Ketelhuisplein, Netherlands.

– Janvi Mangukiya

(+91) 7249196273

(+91) 7249196273