Staircase are provided to access multiple floors in a building. Even with modern inventions like lifts and elevators, stair cases are a must as they are safe during hazards like fires and earthquakes. Staircase and its steel reinforcement is thats why an important aspect in any building design.

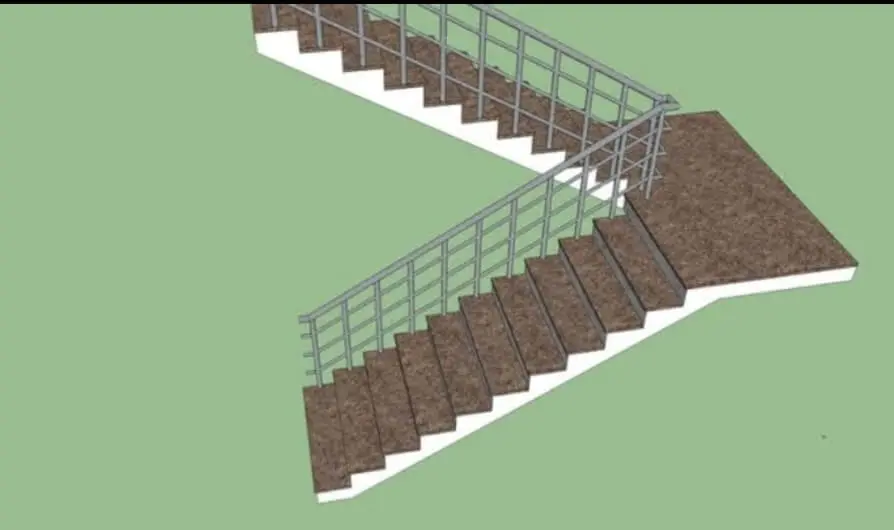

There are multiple types of staircases that architects and engineers use in building design. One common type of staircase used in buildings is Dog legged Staircase.

A Typical Dog Legged Staircase for A House

In this type of staircase, a typical flight between any two floors has 2 ascends with a landing in the center. This type of staircase saves a lot of space and is preferrable for elderly as the landing portion acts as a platform for rest.

In the blog, we understand the design of a typical dog legged stairs. They are some assumptions made for the design like span of stairs, floor height etc., and these might change from building to building. So it is always advisable to get stairs and building designed by a structural engineer before you proceed with any House construction.

Happho provides end-to-end House construction services and we have a dedicated team to design the buildings. So incase you need design services from our end, you can contact here.

design of Dog Legged Staircase

Any staircase has 2 main components. One is a riser and the other is a tread. Riser is the vertical surface of a stair while tread is a horizontal surface where you step on. Sometimes the tread is extended on to the riser to increase its surface area. The overhanging portion is called Nosing.

In a dog legged staircase, usually both the flights are equal. So its enough to design only one flight of staircase.

Design Calculation for Reinforcement Steel:

Data Assumed for Design

- Data :-

Dimensions = (4000× 3000) mm

Floor ht. = 3000 mm

Live Load = 5 kN/sq.m.

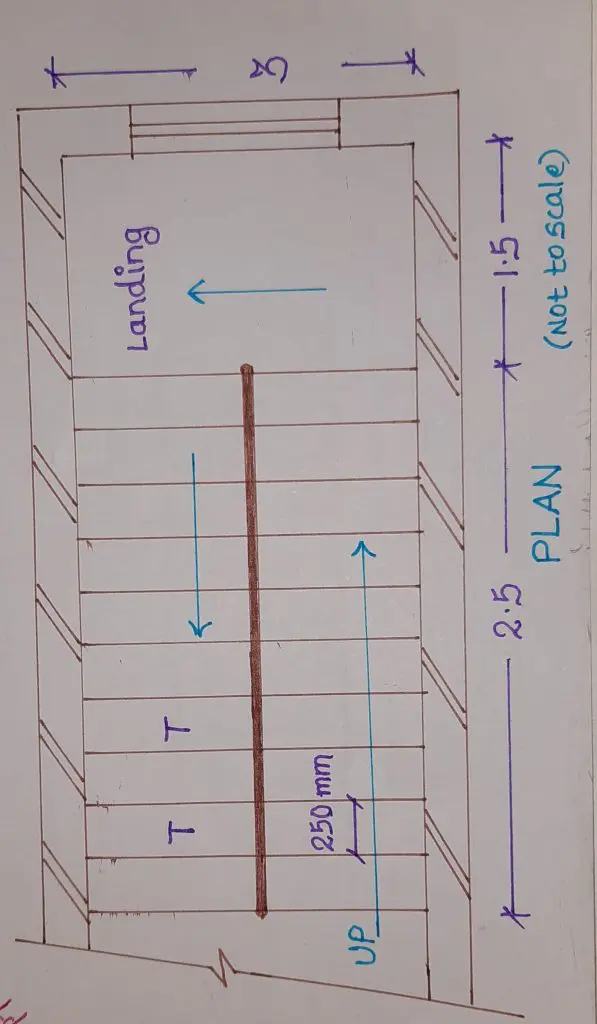

Stair width = 1500 mm

Landing width = 1500 mm

Rise = 150 mm

Tread = 250 mm

Design Calculations of A Staircase

- Of Riser = H/R = 3300/150 = 22

So for a typical 11 feet height building you need 22 stairs or risers.

No. of Riser in 1 flight = 11

No. Of tread in 1 flight = 10

- Going = 250 × 10 = 2500 mm

- Span (L) = 2500 + 1500 + 230 = 4230 mm

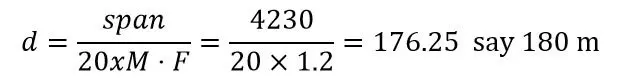

- Waist slab thickness :-

Assume = 0.55 %

M.F. = 1.20 for Fe 415

Cover = 20 mm

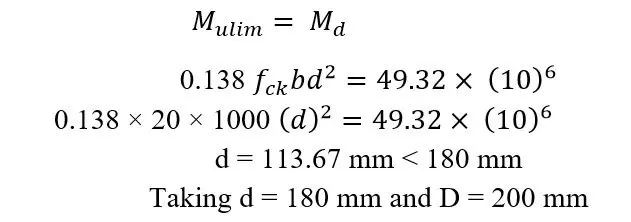

D = d + cover = 180 + 20 = 200 mm

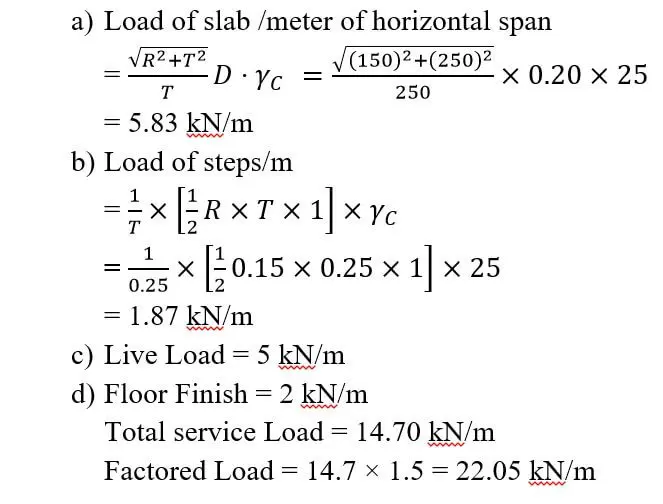

- Loads :-

- Load of slab /meter of horizontal span

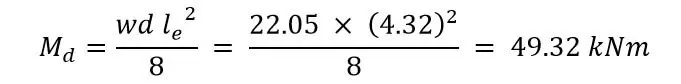

- Factored BM :-

- Required Efficient Depth :–

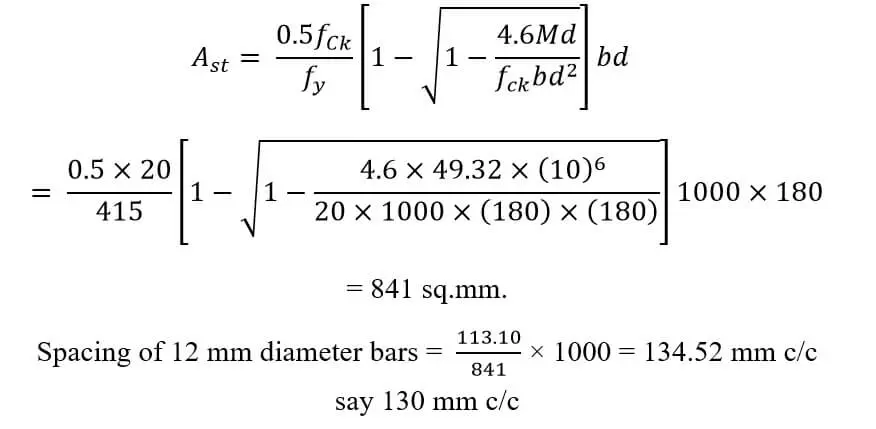

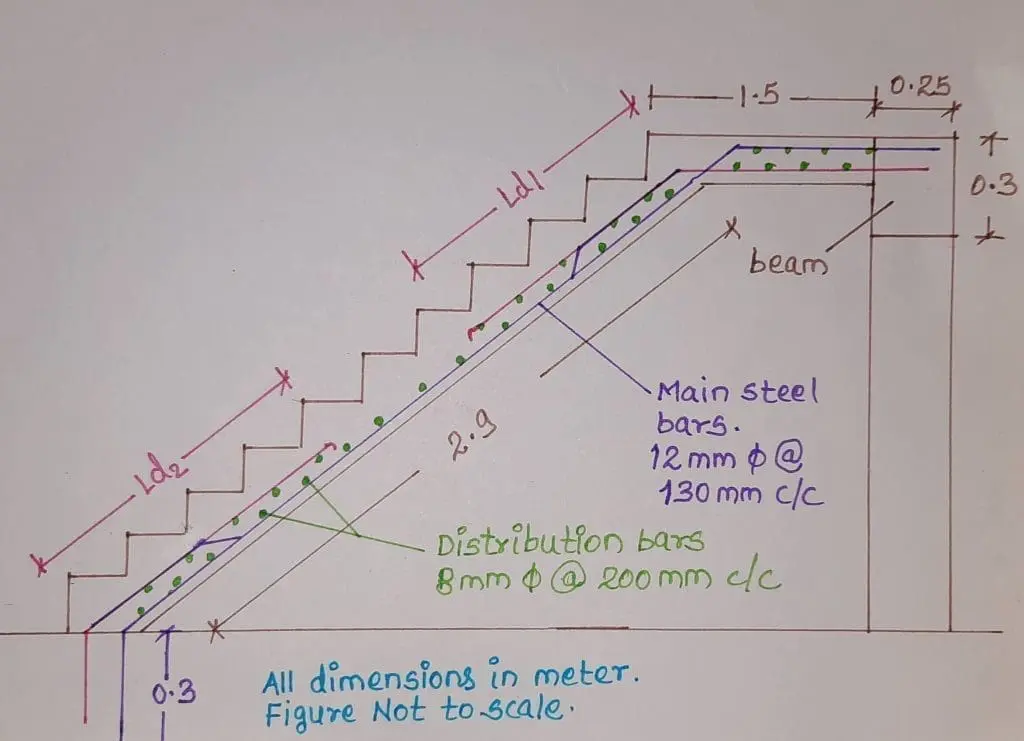

- Main steel and Spacing Calculations:

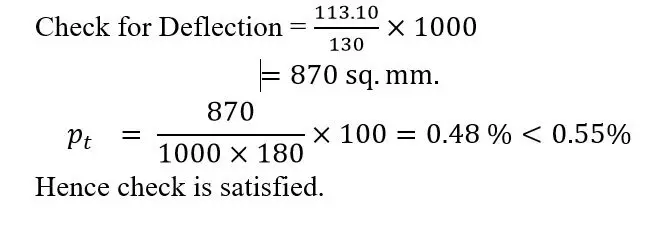

- Check for deflection :-

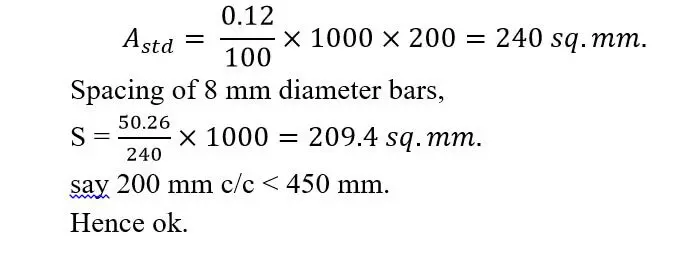

- Distribution steel :

Quantities of Concrete and Steel Required for a Typical Staircase

Concrete Requirement for a Staircase

- Waist slab length = √(0.150²+0.250²)=0.29

Total length = 0.29 × 10 = 2.9 m - Waist slab quantity = l×b×h = 2.9× 1.5×0.2 = 0.87 cu.m (for 1 flight

- Landing = 1.5×1.5×0.2 = 0.45 cu.m (for 1 part)

- Total staircase = (0.87×2)+(0.45×2) =2.64cu.m.

Also Read: Vaastu Principles of a Staircase – Type, Location & Colour

Steel Requirement for A Staircase

To calculate the steel requirement we have to make a bar bending schedule for the Main Steel bar (12 mm dia) and distribution steel bar (8mm). Below is the bar bending schedule for a staircase in a typical house.

Number of Steel Bars To be Ordered for a Typical Staircase:

Standard Length of single bar available at market = 12 meter. (10.56 kg)

Unit weight of a 12mm thick steel bar = 0.89 kg/mtr = 10.68 kgs (for a 12 mtr length bar)

Unit weight of a 8 mm thick steel bar = 0.395 kg/mtr = 4.74 kgs (for a 12 mtr length bar)

Total No. Of 12 mm dia. Bars to be ordered

= Weight of 12mm steel required / Weight of 12mm thick steel bar (12 mtrs)

= 192.051/10.68 = 17.8 bars (say 18 bars)

Total quantity of 8 mm dia. Bars = 53.78 kg.

Total No. Of 8 mm dia. Bars to be ordered

= Weight of 8 mm steel required / Weight of 8 mm thick steel bar (12 mtrs)

= 53.78/4.74 = 11.34 (say 12 bars)

So You would need 18 Nos of 12 mm steel bars and 12 Nos of 8 mm steel bars for constructing one flight of a typical dog legged staircase

P.S. : As mentioned earlier also, these are not standard designs for any buildings. The design parameters changes for building to building. So its highly advised to get the building and staircase designed by a structural engineer. The design calculations are just for reference incase you need to verify the quantities calculated.

– Vrushali Pathak