Dewatering is a process of removal of water from soil below ground levels i.e. from trenches/pits done for construction of substructure of any building. It is basic and important step in construction process of structure. It is done in various methods as per project requirements. Process can be done manually for small projects and mechanically for large projects.

Necessity of Dewatering

- To reduce water table levels and make soil dry which further serves easy excavation of soil.

- To ensure stability of of excavation slopes which suits to supporting structure.

- To improve physical properties of soil and hard strata below substructure.

- To control water pressure exerted by soil on substructure

Methods of Dewatering

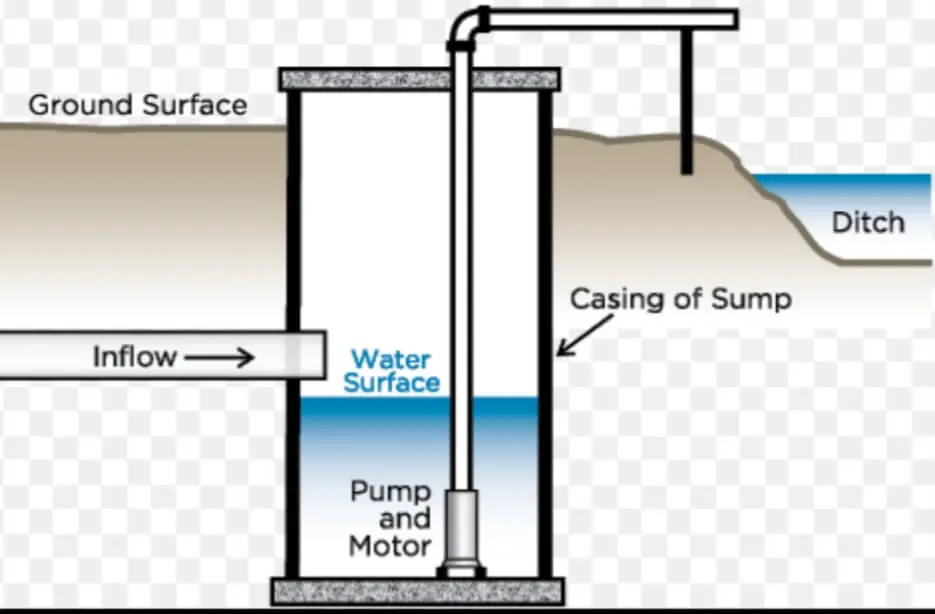

1. Open Sumps and Ditches

In this method, shallow sumps and ditches are dug at the periphery of area to be de-watered.

Water is removed with the help of pump.

This method is adopted for removal of water from small infiltration and surface waters at shallow depths.

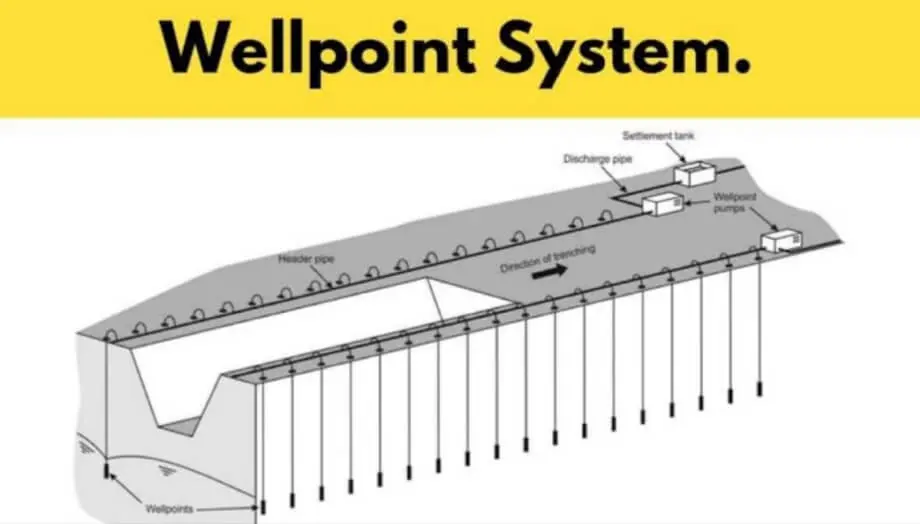

2. Well Point System

This method consists of pipe with dimensions meter length, 5 to 8 cm diameter, wire gauge screen (which acts as strainer), header pipe, pumping unit.

Perforated pipe is driven in to ground 1 to 2 meter apart.

Upper ends are joint to header pipe.

This header pipe is connected to self priming pumpsamd thus water is pumped out.

This method is used for dewatering at a depth of 10 to 15 meters below ground level.

Used for building excavations (multi storeyed and high rise structures).

Also Read: Can House Construction Be Started in Rainy Season

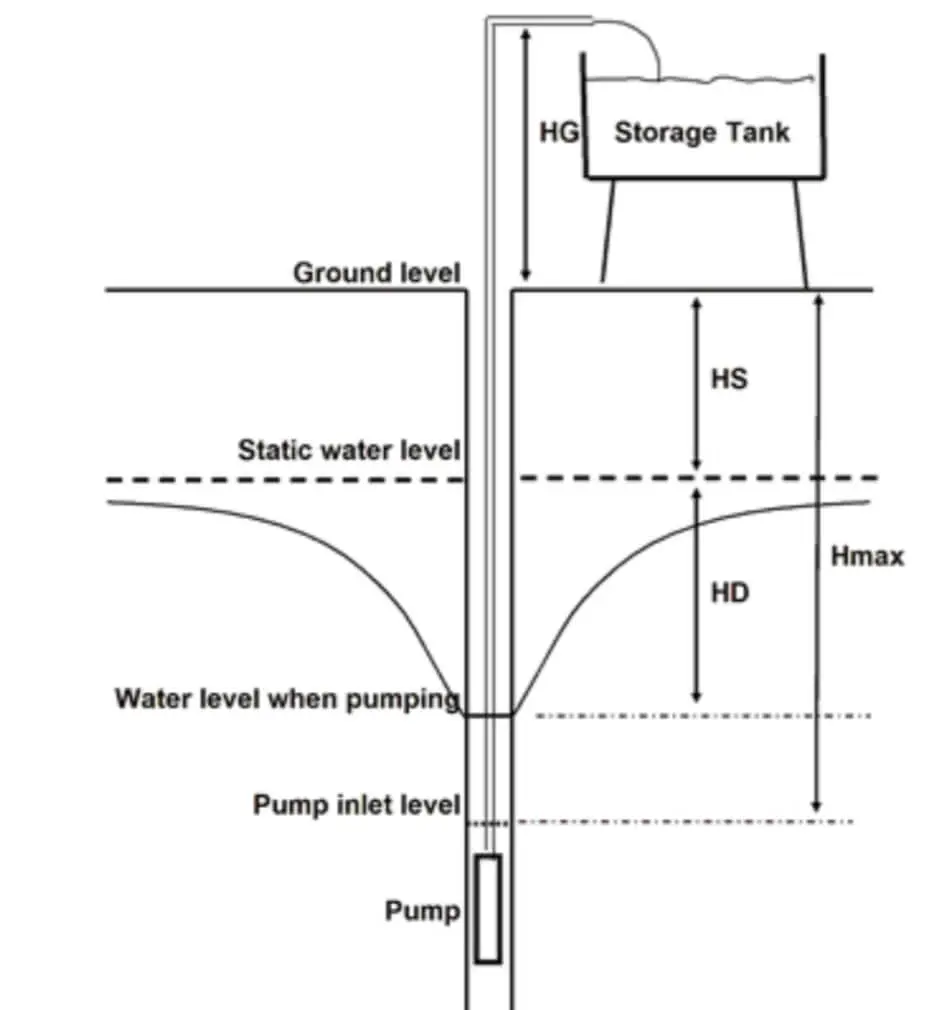

3. Deep Well Point System

A hole of 45 cm diameter is done around the well point.

Deep well pump is inserted in perforated pipe.

Water is then removed from the hole with the help of pipe.

This method is adopted for depths greater than 15 meters and large excavation areas.

Can be used for excavation of dams, tunnels, shafts.

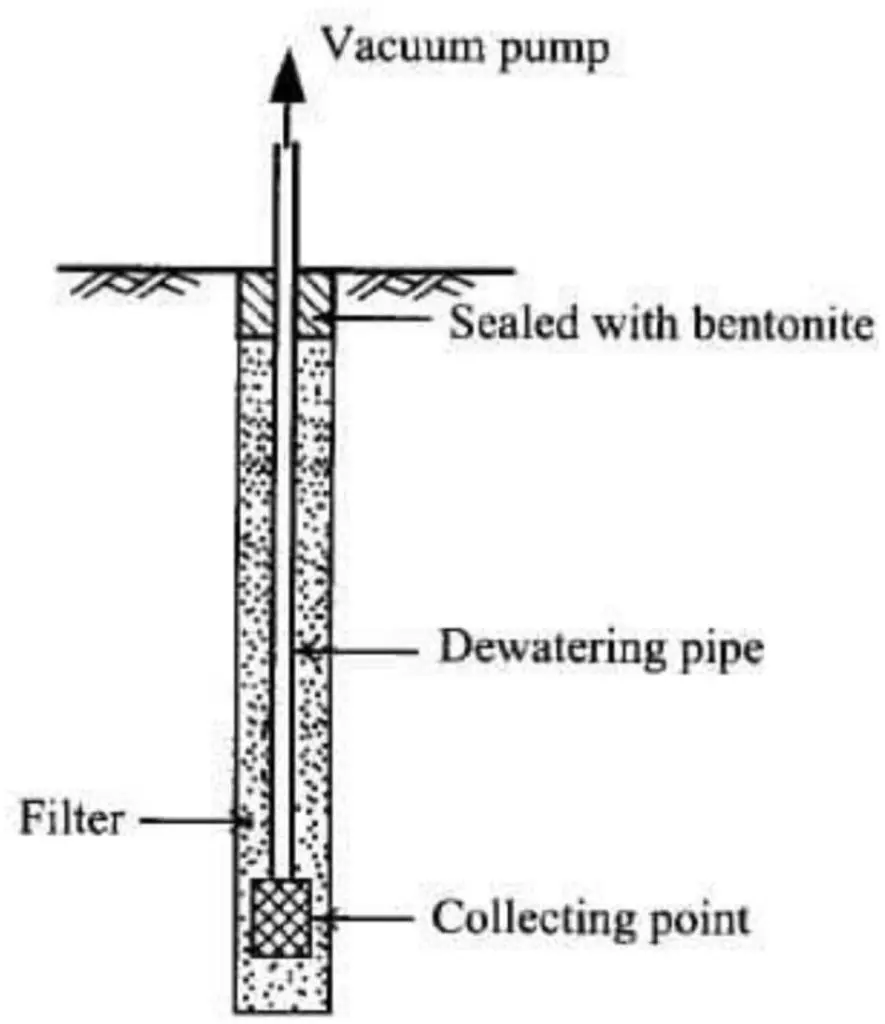

4. Vacuum method

A hole of about25 cm diameter is formed around well point.

Corse sand is filled up to 1 meter. Cement, clay, sand can be used as sealing material.

Due to pressure difference in atmosphere and water table level, water can be removed with the help of vacuum pump from these holes.

Used for excavated layered soil.

Also Read: Which Season is Best Suitable for Construction In India

Precautions to be Taken In De-watering Process

- Site selection and study of soil properties should be done thoroughly.

- Pre-drain process should be done wherever necessary before dewatering.

- Pumps should be used as per the method adopted for dewatering.

- Side slopes should not be disturbed.

- Skilled labour work is required for this process under experienced supervisors/professionals.

- Selection of method dewatering should be based on location of site, availability of machines/tools/equipment, depth of excavation, type of soil, water table levels, permeability of soil.

- Power sources should be ensured with continuous supply.

- Duration should be as minimum as possible with respect to Project requirements.

- Process should be economical and suitable to project cost.

– Vrushali Pathak