Concealed Conduit Electrical Wiring systems are the most popular, aesthetically appealing, and most common type of House Electrical wiring used. Conduit wiring is a professional way of wiring a building. Mostly PVC conduits are used in domestic wiring.

The conduit protects the wires from external damages like rodents etc., increasing the longevity of the wires used. Before talking about the installation procedure, lets talk about what house electrical wiring system is and their different types.

Different Types of House Electrical Wiring Systems

House Electrical wiring is distributing the electricity (electrical energy) from suppliers meter board to various appliances in the home like lights, fans, TV etc., There are lot of different types of house electrical wiring systems used in India and other countries. Few of them are:

1. Cleat Wiring

Cleats with groves are used to hold the cable. It is a temporary wiring system so not used in typical house constructions

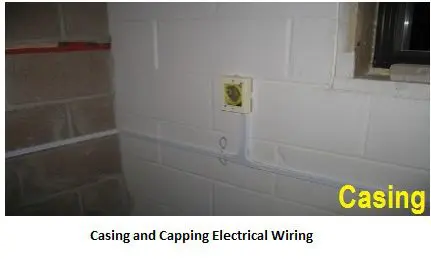

2. Casing Wiring

Open wiring system where the wires are run through casing enclosure and capping is used to cover the casing.

3. Batten Wiring

Single or a group of wires are laid over a wooden batten. The wires are hold to the batten using a brass clip, which is attached to the wooden battens at an interval of 10-15 cms

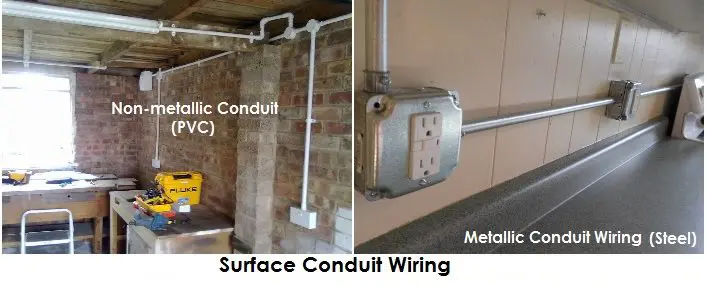

4. Surface Conduit Wiring

PVC or GI conduits are laid on the surface of the wall or ceiling. These conduits are attached to the walls with a 2-hole strap and base clip at a regular certain distances. Electrical wires are laid inside the conduits.

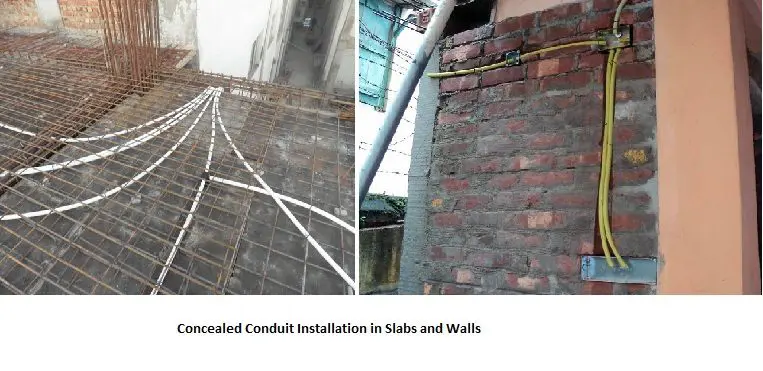

5. Concealed Conduit Wiring

PVC conduit pipes are placed inside the chiselled brick/block wall before plaster. The wall is later completely plastered and painted. Electrical wires are laid inside the conduits. This type of wiring are aesthetically appealing since they are no electrical wires/conduits seen on the top of the wall.

Advantages and Disadvantages of Concealed Conduit wiring System

Advantages of Concealed Electrical Wiring System

- It is the safest wiring system of all the ones mentioned above

- It is Aesthetically appealing

- There is no risk of fire or mechanical wear and tear

- There is no risk of damaged cable insulation

- It is safe from humidity, chemical affects and smoke

- There is No risk of shock

- Its most Reliable and popular wiring system

- Do not hamper interior layout as conduits are concealed in wall

- Renovations can be easily performed as old wires can be easily replaced

Disadvantages of Concealed Electrical Wiring System

- Its expensive when compared to other surface conducting methods

- Its very hard to find any defects in the wiring

- Adding additional conduit in future is cumbersome (Needs wall chiselling and finishing)

- Changing of location of appliances or switches is difficult

- Installation is difficult as compared to other methods

- Complicated to add/manage additional connection in the future

Step by Step Procedure to Install Concealed Conduit Wiring System

Step-1: Laying of Electrical Conduit in Slab

- Slab conduits for house wiring should be done in 2 mm thick 25 mm size FR PVC conduits. Preferably Slab conduits shall be laid in between top and bottom reinforcement. Please ensure concrete thickness i.e. cover to PVC Conduits incase of singly reinforced slabs.

- Only Deep junction boxes shall be used in slabs. With Binding wire, properly bind the PVC conduits

- Preferably follow different color coding for conduits for data (LAN wire, telephone wire etc.,) and electrical wires

- Use grey PVC pipes for data and black PVC pipes for electrical wires. Use PVC solvent for jointing the accessories

- Wall drops shall be properly checked for face of wall/beam. Please ensure concrete thickness i.e. cover

- All the conducting shall be checked as per services drawing, which contains locations of switchboards and number of points to be installed at each location.

- Special precaution shall be taken during concreting of slab.

- All broken pipes are to be replaced

- All joints have are to be watertight joints to avoid choke up)

- GI wire passing shall be carried out immediately after de-shuttering of slab & beam. (any choke up to be documented and alternate routing to be shown in shop drawings and documented for future references).

- All necessary sleeves shall be provided in beams, columns, prior to slab casting as per electrical & air-conditioning.

- Pull boxes shall be provided at suitable locations.

- The pull and junction boxes shall not be clustered at one place and shall be so arranged that they should not be easily seen from heavy movement areas as per electrical drawings.

Step-2: Laying of Electrical Conduits in Walls

- The concealed conduit work shall be carried after construction of masonry walls but prior to plaster.

- Chasing work shall be carried out after completion of curing of brickwork (at least 7 days gap from brickwork).

- The wall chasing should be done with wall cutters only,this would avoid damage to walls.

- The conduits shall be fixed with approved clips to ensure proper routing and wiring later.

- After fixing the conduits, boxes, and accessories, the chiseled surface should be filled with cement mortar and chick mesh wrapped around conduits.

- Wall conducting activity shall start with level marking on the wall (usually box level),knowing its height above FFL(Finished floor level)

- The width of chasing shall be limited as per number of conduits.

- The depth of chasing to have conduit recess at least 10mm from masonry wall.

- All horizontal conduit runs shall be straight at box level. Light point conduit shall run straight vertical to switch box. No wall conduit shall be taken haphazardly.

- No Elbows & bends shall be used. In case of change in direction in pipe use spring to bend the pipe.

- Power conduits should not be run near any communication line.

- Conduits above false ceiling shall run with proper supports / suspenders. Conduits shall not be rested on false ceiling grid in any case. All vertical runs with open ends shall be sealed at top in case of false ceiling work, while masonry civil works going on.

Step-3: Installation of Switch Board Back Boxes

- All concealed switch board shall be fixed properly in level as per given schedule (Height, distance from Finished Floor (FFL) should be as per architect’s recommendation)

- The gap between two concealed switch boards shall be uniform & maintain same for all installation.

- The switchboards shall be readymade modular type metal boxes of approved makes & drawing.

- Concealed box shall be fixed 3 mm below the plastered surface.

- Box fixing shall be done before plastering work along with wall conduiting. These boxes shall be filled with thermocol while plastering work.

Step-4: Installation of Distribution Boards

- DB’s shall be concealed before plaster work

- DB box shall be fixed in proper line & level in the recess provided in brickwork

- DB’s shall be ready-made as per design (fixing no. of conduits pipe entering DB)

- All PVC pipes shall enter in to DB from given entry holes only