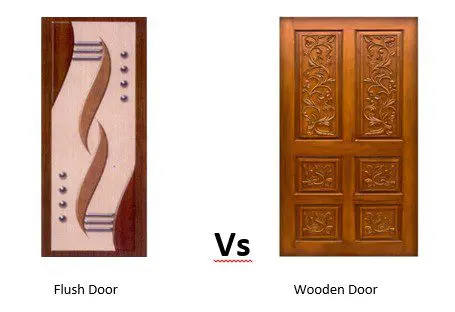

Flush Door

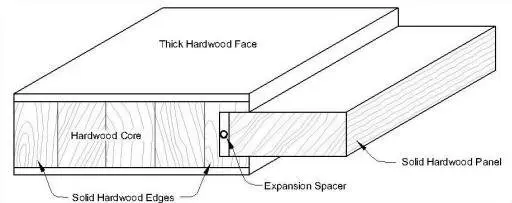

A flush Door has completely smooth surfaces and are made by sandwiching plywood or MDF Board over light timber frame. The Hollow part between these Doors are filled with cardboard/hardwood. The flush doors can be finished with either laminates or veneer.

Cross Section of A Typical Flush Door

Wooden Doors

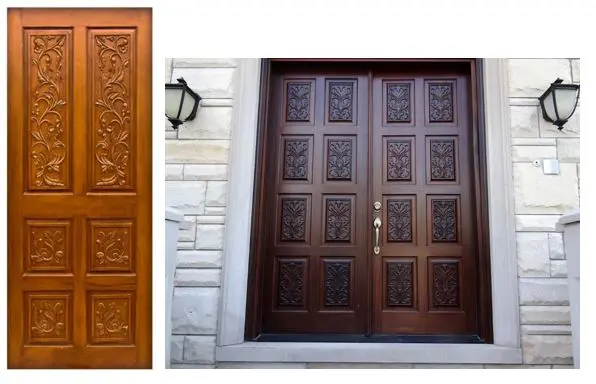

Wooden Doors are completely manufactured out of solid wood. There are various types of wooden doors available in the market like Paneled Door, Battened Door etc. These Doors are manufactured by joining wooden panels the are cut in the as per required size and design. Wooden Doors can be finished using oil, wax, spirit polishing etc., which gives them a great aesthetic look.

Comparison between Wooden and flush Door on various Parameters

| Factor | Flush Door | Wooden Door |

| 1.Raw material Used | Flush Door are made by using Timber frame which are Covered by plywood or MDF on both sides of door and hollow portion of door filled with cardboards/hardwood. These Doors are then finished by veneer on top or teak ply etc. These doors have less joints with perfectly flush. | Wooden Door is made from wood totally. There are various types of doors are available like Paneled door, Battened door, Glazed door etc. In these type of door panels of wood are joined together as per Design or requirement. The frame is grooved on the inside edges to receive one or more panels. |

| 2Cleaning & Maintenance Required | Flush doors have plain shutters so they are easy to maintain and clean as they don’t have Designs or grooves in which dust will gather. The doors either have veneer finish or laminate finish.so for cleaning you just need to wipe out door with clean dry cloth. | Wooden shutters take more time and cost for cleaning and maintaining as it have lot of designs and grooves in which dust will gather. |

| Thickness of Shutters | Flush Door Usually available in market with thickness 25mm, 30 mm and 35 mm. But as per requirement you can manufacture any thickness flush door can manufacture. | Wooden Door Usually available in market with thickness 25mm, 30 mm and 35 mm. But as per requirement you can manufacture any thickness flush door can manufacture. |

| Finishing | Flush doors are generally finished with veneer and polish over it or it may finish with Laminate over ply or MDF used on it. | Wooden doors can finish with various ways using ingredients such as oil, paint, wax polishing and spirit polishing directly on wood or it can finished with laminate fixing on wooden doors. |

| Advantages | 1. They are less expensive. 2. It can’t split, peel or rot and don’t require periodic maintenance. 3. They are resistant to stains, scratches and crash. 4. They are easy to clean. They are resistant to termite than wooden doors. |

1. Wooden doors can cut and adjusted to any size and minor changes can easily done at site. 2. Wooden doors have lot of designs than flush door. 3. Carving can done on wooden doors. |

| Disadvantages | 1. Flush doors are manufactured in factory so you have to provide exact size of door otherwise it will be very hard to redo the size. 2. Carvings Can’t done on Flush Door. |

Wooden doors are more to termite attack than any other materials available in market except Teak wood Doors. |

| Strength | Flush Doors have good strength but not as good as wooden door. | Wooden door have better strength than flush door with better lifespan. |

| Aesthetical Appearance | Flush door are cost effective but they are not aesthetical appealing as Wooden door. | Wooden doors are aesthetically more appealing than flush doors. |

Typical Look of Flush Door

Wooden Doors with Carvings