An aspiring design demands importance to details with visual aesthetics. Spatial arrangements in your home may be distinct with the type of enclosure and volumetric aura. They may be enclosed, Semi-open and open depending upon the usage.

Semi-Open spaces in your home designs may be subject to aesthetic appeal with distinctive constructional and materialistic detail. These semi-open spatial arrangements can be covered with various design ideas that can also be executed through roofing sheets. These roofing sheets can be used for creating temporary structures and as well as protecting the actual roof from external elements.

These roofing solutions are generally a huge financial investment, so it would be better to familiarise with the types and variations that can match your needs.

Locations Where Roofing sheets Are Used

A general observation is noted that roofing sheets are installed at places with semi-open or temporary approach of spatial arrangement in domestic, industrial, and commercial projects. These can be installed at various places like:A general observation is noted that roofing sheets are installed at places with semi-open or temporary approach of spatial arrangement in domestic, industrial, and commercial projects. These can be installed at various places like:

Applications In House Construction

- Garges

- Porches

- Temporary or Permanent Sheds

- Garden Seating or Shacks

- Swimming Pool Deck Seatings

- Skylights

- Walkways

- Patios

- Sunrooms

Other Applications of Roofing Sheets:

- Commercial Warehouses

- Temporary Hospital Bedding Structures

- Externsion Plotting

- Construction Site Offices

- Demo Structures for Clients with False Ceiling

- Agricultural Setups

Types of Roofing Sheets Available in India and Their Comparison

| Material | Galvanized Steel | PVC Plasticol | Polycarbonate | Asbestos Sheet | Plastic |

| Type | Cold Rooled | Hot Dipped Galvanised steel substrate | Mechanical-Vaccum Formed | Wet Mix Casted | Casted or Extrusion Based |

| Available Sizes | 3.5’x 10/12/14/16 | 18’ max. | 12.2x 2.4 mtr or 2.05 x 3.05 mtr | 1.5/1.75/2.0/2.25/ 2.75/3.0/3.6 mtr x 1.05 mtr | 4’ x 10’ |

| Weight | 12.9-19 kg/sq. mtr. For 13 gauge | 6.9kg/m2 | 1.42-1.70kg/ sq mtr | 12-16 kg/sq. mtr | 2.25 kg/ sq. mtr. |

| Cost | 295rs/sq. mtr-350rs/sq. mtr | 250-500rs/ sq. mtr. | 450rs /sq mtr- 1050rs sq. mtr. | 150rs -200rs/ sq. mtr. | 400rs/sq. mtr-550 rs/sq. mtr |

| LifeSpan | 25-30 years | Upto 30 years | Around 25 years | 30 years approx | 20 years approx |

| Surface Treatment | Polyester paints, plastisol coating | PVC rolled over steel sheets | Resin treated | UV film | |

Installation Technique | Lap jointed, bolted, screwed | Lap jointed, groove finish | Frame-Clamped | Overlapped-bolted, groove filled | Drilled and framed in suitable channels |

Additional Features | Scratch Resistant, Fire Resistant | Fade Resistant, Scratch Resistant | Clear finish, Highly Insulated, Fire Resistant | Easy to install | Variant Colours and Textures |

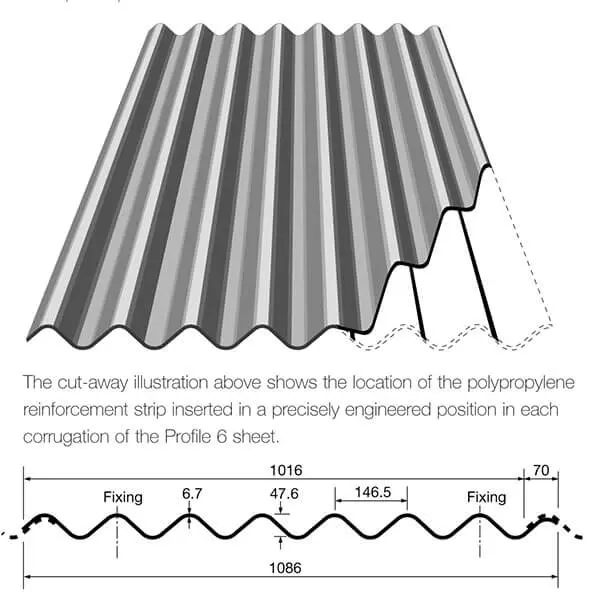

1. Corrugated Sections

Corrugated refers to repetitive fold section sheets. These type of sheets intensifies the roof’s integrity. Corrugated sheets are durable and structurally sound when compared to flat counterparts in similar materials.

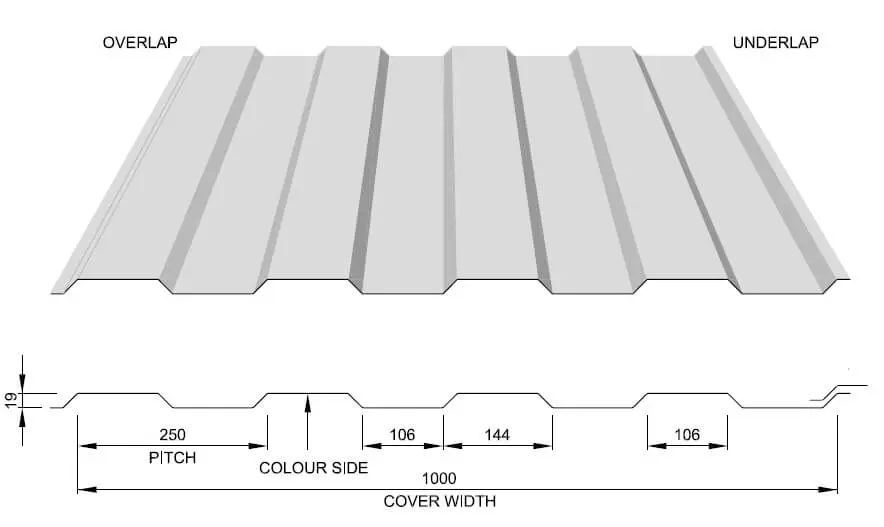

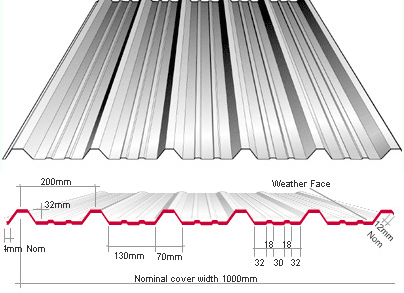

These are available in regular corrugated section and as well as corrugation in corrugated in unit. The latter option provides better rigidity due to structural force distribution. Their corrugated design with ridges and grooves makes them reliable with enhanced strength.

2. Metal Roofing Sheets

Metal roofing sheets are environment friendly roofing solutions as they are highly recyclable. They are highly durable and have a long life expectancy. These are good acoustic insulators with varied textured and plain finishes. Their base material is basically Zinc or steel.

Metal roofings are expensive than other variants but if calculated by the lifespan and durability, the metal roofing solution pays back the investment generally.

3. Glavanized Steel Sheets

Carbon Steel when coated with zinc produced through continuous hot dipping process. Usual usage is bare, coated or painted sheets chose according to weathering effect it has to withstand.

Galvanised steel sheets are basic base material for major roofing sheets in corrugated and plain sheet form. These can be protected with coated polyester paint or PVC plastisol coated paints.

4. Plastic Roofing Sheets

Plastic roofing sheets include polycarbonate, acrylic, polystyrene and PVC variants. They can be completely transparent or customised according to privacy. Plastic variants usually create considerable amount of noise when subjected to rain impacts.

5. PVC Plastisol Sheets

These sheets are highly durable. General base material in these sheets is Steel which is treated with primer paint for rust protection and shine. These steel base sheets are called PVC plastisol because PVC is rolled on their surface and they are scratch resistant with typical lifespan of 25-30 years.

6. Polycarbonate Sheets

Polycarbonate sheets are used in industrial and commercial large scale implications. They are easy to install, weather resistant and extremely durable. Their maintenance cost is very low and is available in various textures and designs.

Polycarbonate sheets are good insulators, these are available in clear finish and foam backed sheets.

Clear polycarbonates are often featured in sunrooms and patios with UV protective film layers. These sheets have polypropylene resin as their base material and are available in various color choices.

7. Asbestos Cement Roofing Sheet

Asbestos cement refers to fibrous cement that is used to reinforce thin rigid cement sheets. These are affordable and durable solution in terms of fire safety. These are moulded sheets in form of corrugated sections.

Due to fibrous composition, asbestos when exposed to weather and erosion elements can be susceptible to airborne diseases. They are cleaned with pressure washers to prohibit fibre suspension in air.

– Anshul Kulshreshta